An automobile front upper member assembly structure

A technology of front upper component and assembly structure, which is applied in the direction of upper structure sub-assembly, upper structure, vehicle parts, etc., can solve problems that do not involve the installation of new array type automobile headlights, and achieve increased strength, stiffness, and clearance Consistent and guaranteed effect of height difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

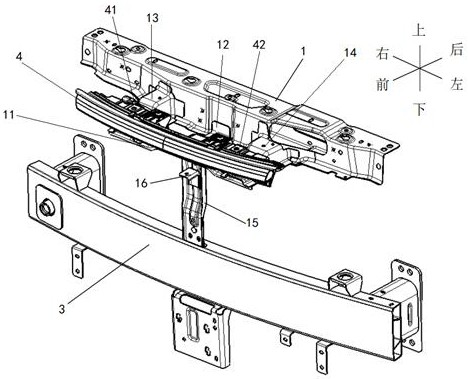

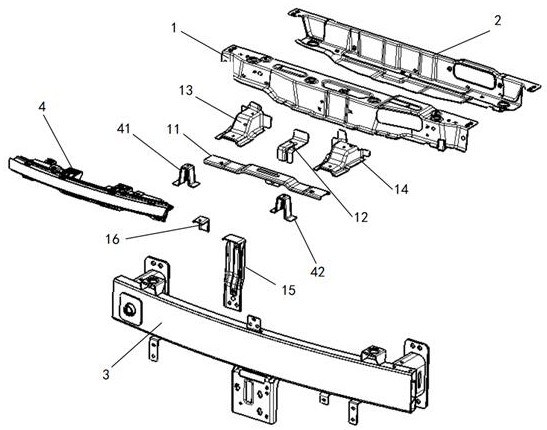

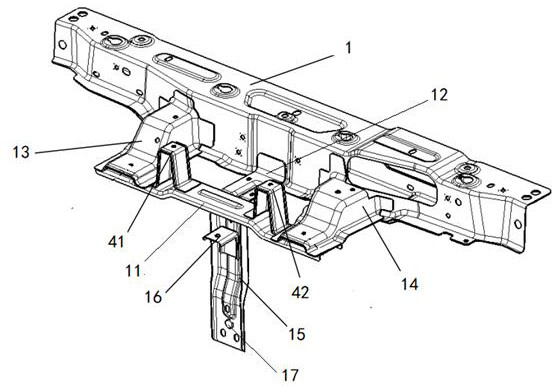

[0028] The present invention will be described in detail below with reference to the accompanying drawings.

[0029] see Figure 1 to Figure 4 The shown assembly structure of the front upper component of an automobile includes a front upper component body 1, a radiator upper mounting plate 2 connected behind the front upper component body, the front upper component body is located on the outside of the vehicle body, and the radiator is mounted on the radiator. The mounting plate is located on the inner side of the vehicle body, and the two are connected by spot welding to form a cavity structure to improve the main body strength and rigidity of the front upper member assembly. It also includes the front protection right installation bracket 13, the front protection left installation bracket 14 and the front collision beam 3, which are characterized by:

[0030] A middle beam 11 is located in front of and parallel to the front upper member body 1, and the middle portion of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com