A vertical material system for cylindrical materials

A cylindrical, vertical material technology, applied in the direction of conveyor objects, vibrating conveyors, transportation and packaging, etc., can solve the problems of poor vertical material stability and low efficiency, achieve high stability, improve detection efficiency, and improve conveying efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

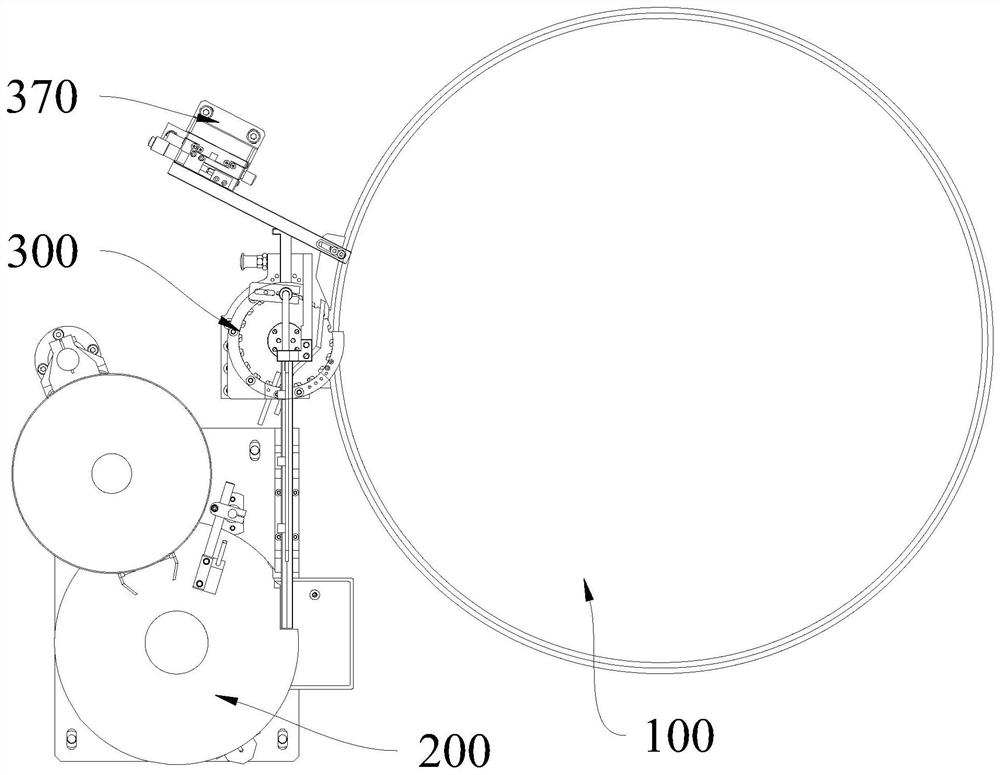

[0053] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings. Among them, the directional nouns such as "up" and "down" mentioned in this article are based on figure 1 orientation as a reference.

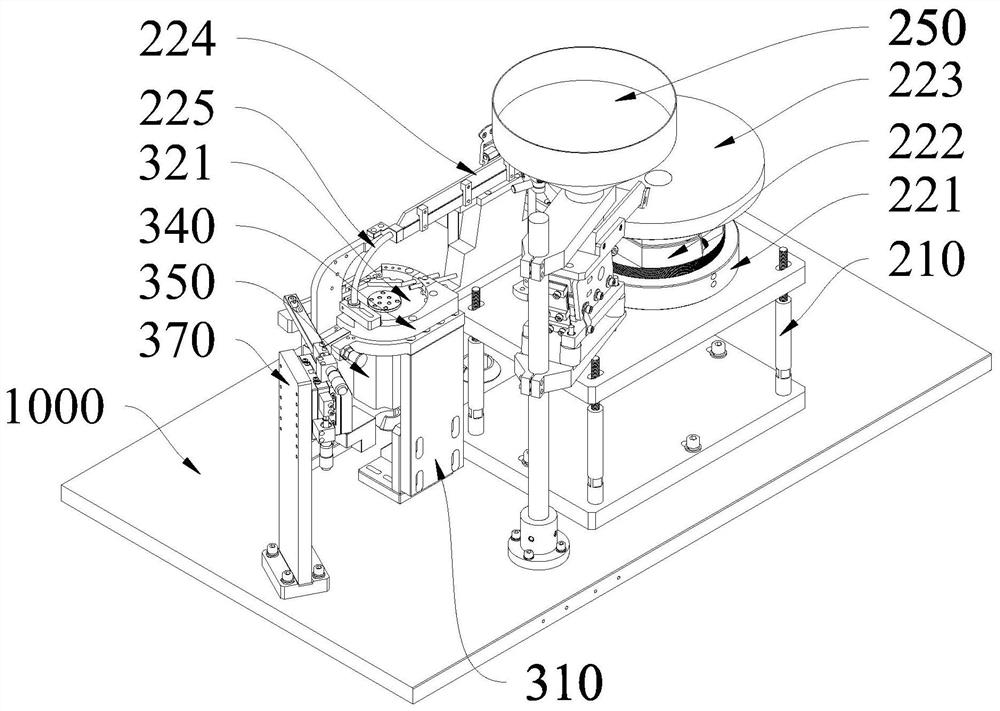

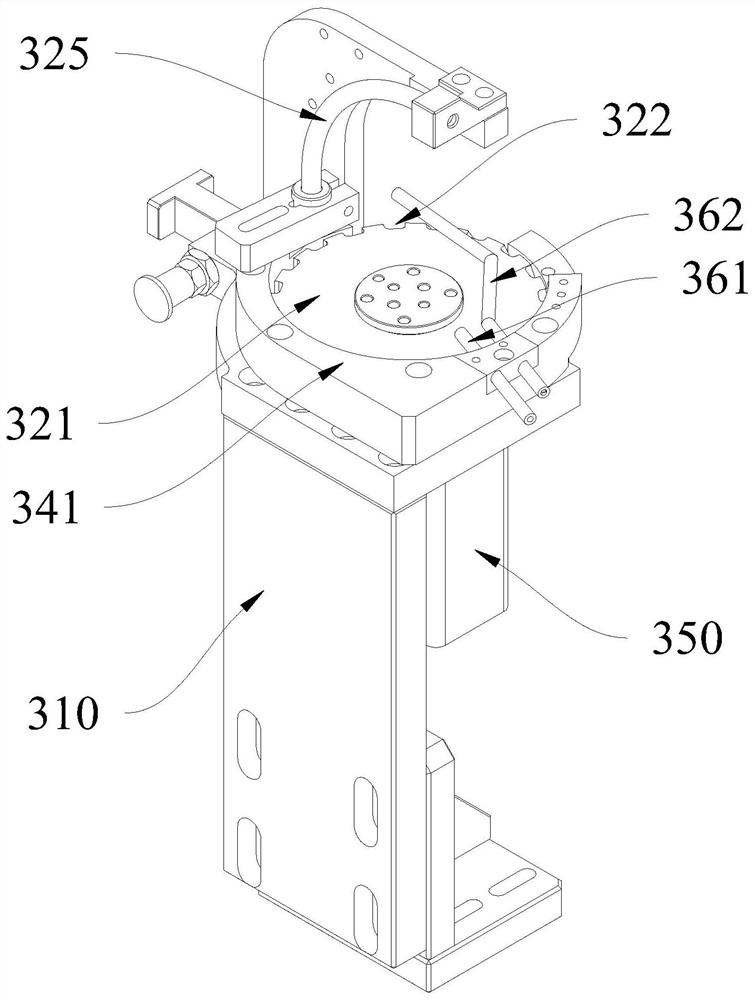

[0054]The embodiment of the present invention proposes a vertical feeding system for cylindrical materials, which solves the technical problems of poor vertical stability and low efficiency during the feeding process of cylindrical materials 110 . The vertical feeding system for cylindrical materials includes a material sorting device 200 and a vertical feeding device 300. The material sorting device 200 includes a vibrating plate mechanism and a loading bin 250. The outlet of the charging bin 250 is connected to the inlet of the vibrating disc mechanism. The vertical material device 300 includes a vertical material tray mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com