Method for preventing heavy tank accidents of coke dry quenching electric locomotive

A technology of electric locomotive and CDQ, which is applied in the direction of coke cooling, coke oven, electrical program control, etc., can solve the problems of CDQ production safety threats, not being properly solved, tank heavy tank accidents, etc., to reduce labor Operation strength, easy maintenance, high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

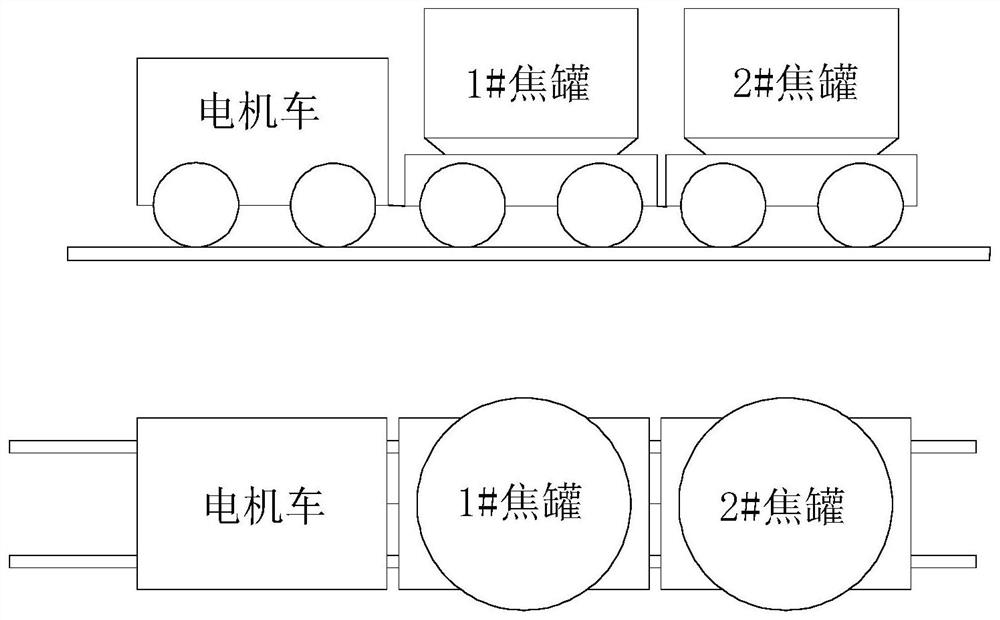

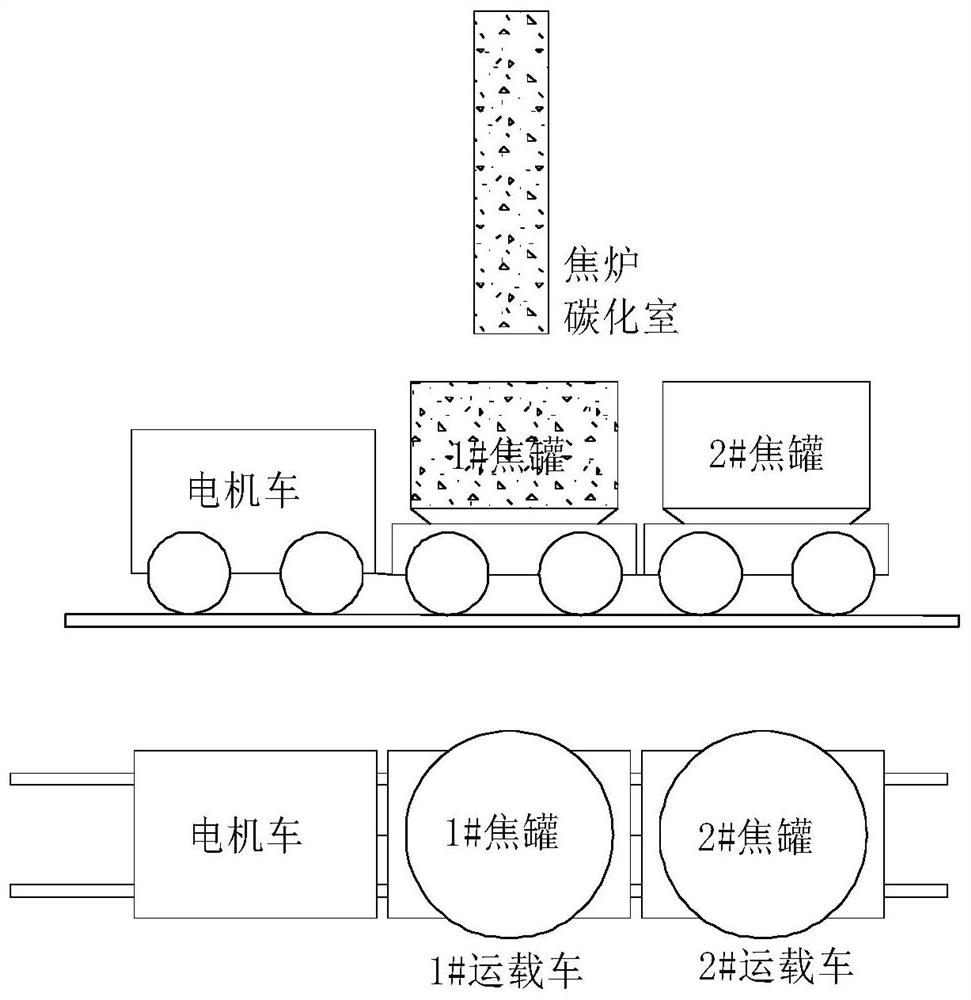

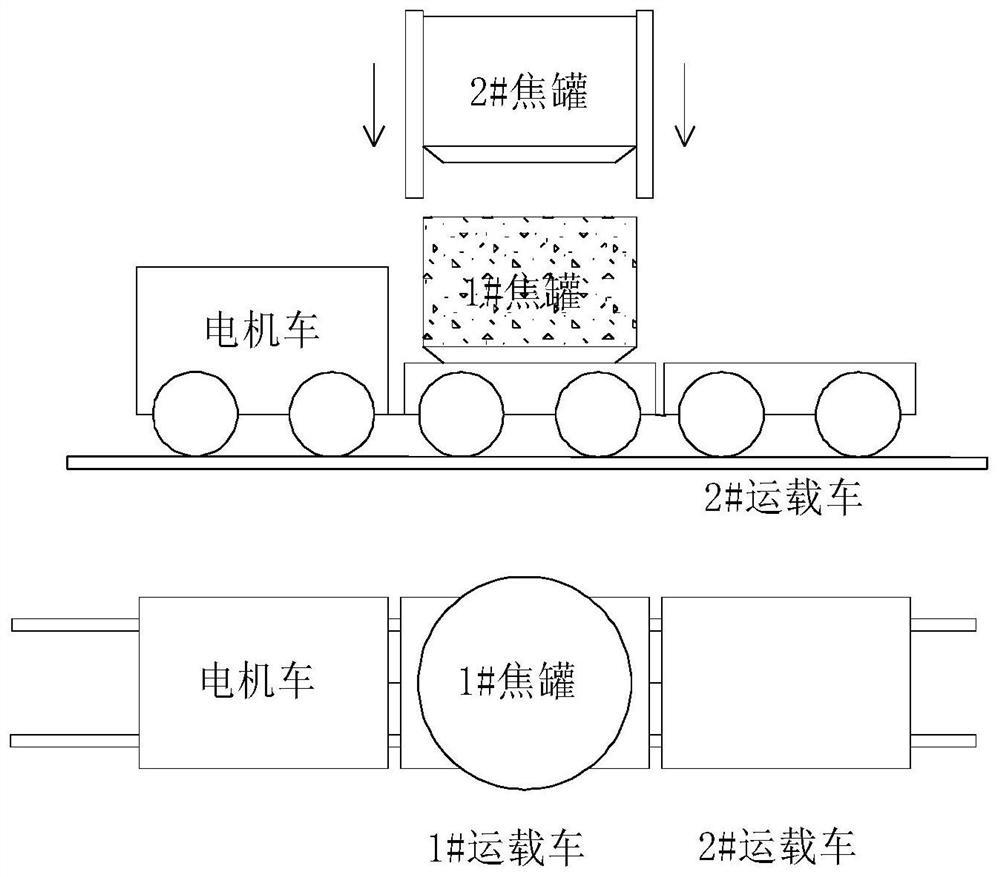

[0022] Example 1: see Figure 1-Figure 5 , a method for preventing heavy tank accidents of CDQ electric locomotives, the method adds a set of coke tank state detection equipment to the coke tank, and then relies on logic control methods to logically control various detection signals so as to realize the coke tank of electric locomotives Safe work, wherein an additional set of coke tank state detection equipment includes a coke tank temperature measuring device, a coke tank presence or absence detection device, and a coke tank weight weighing device. The coke tank temperature measuring device is installed on the outer edge of the coke tank and used It is used to detect the temperature T of the coke in the coke tank, and is used to judge whether there is red coke in the tank; whether there is a detection device for the coke tank, which is installed on the carrier vehicle near the coke tank, and is used to detect whether the coke tank is on the carrier vehicle; The coke pot weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com