Efficient two-for-one twisting stranding machine

A plying machine and ply twisting machine technology, which is applied to spinning machines, continuous winding spinning machines, textiles and papermaking, etc. It can solve the problems of insufficient sealing of gear reduction boxes, poor production cycle capability, and high production costs, etc. To solve the problem, to achieve the effect of stable rigidity, not easy to get stuck, and improve twisting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

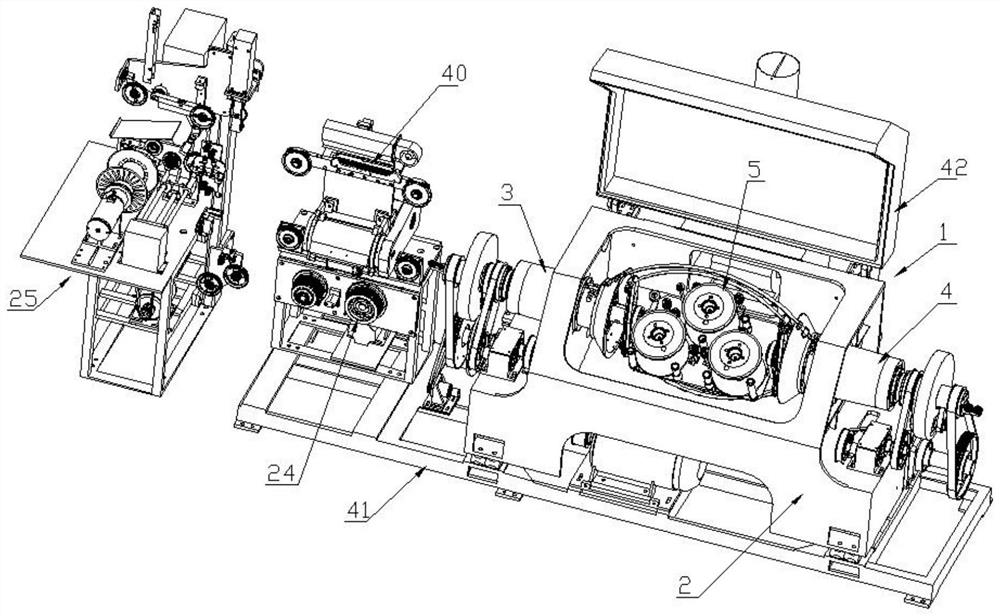

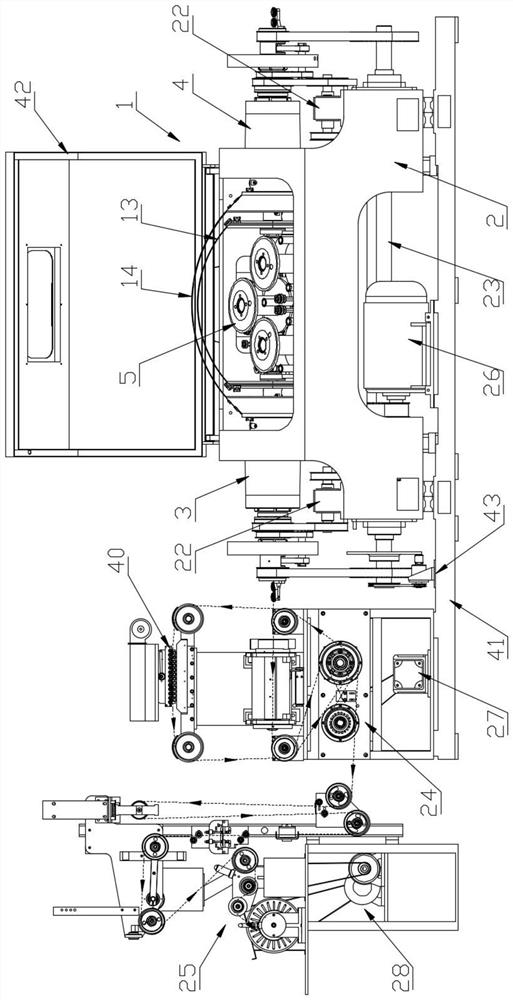

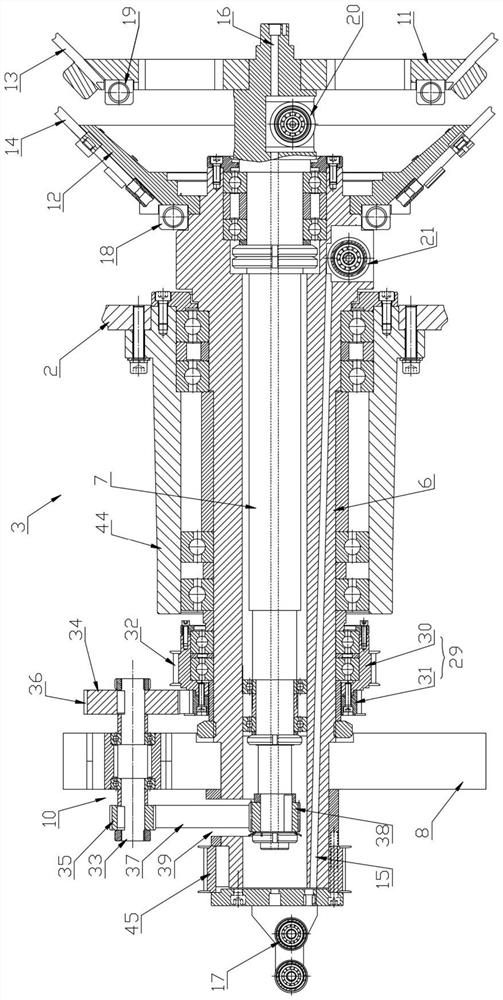

[0036] refer to Figure 1 to Figure 9 , the present invention provides a kind of high-efficiency two-for-one twisting and plying machine, comprising plying machine 1, plying machine 1 comprises fuselage support 2 and left spindle device 3 and right spindle device 4 that are symmetrically installed on fuselage support 2, left spindle device 3 The same structure as the right spindle device 4; a cradle device 5 is installed between the left spindle device 3 and the right spindle device 4; the left spindle device 3 includes a hollow outer spindle 6, an inner spindle 7 and a rotating bearing fixed on the outer spindle 6 The seat 8 and the inner core shaft 7 are rotatably fitted in the outer main shaft 6, which can greatly shorten the size in the axial direction compared with the side-by-side arrangement, thereby reducing the overall size of the entire device and simplifying the mechanism; the outer main shaft of this embodiment 6 is rotatably installed with a central reversing asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com