Corrosion steel reinforcement system for bridge reinforcement

A technology for steel bars and bridges, applied in the field of corroded steel bar reinforcement systems for bridge reinforcement, can solve problems such as being unsuitable for mass installation, difficult for operators, and insufficient connection strength, so as to improve work efficiency, good work results, and ensure work. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

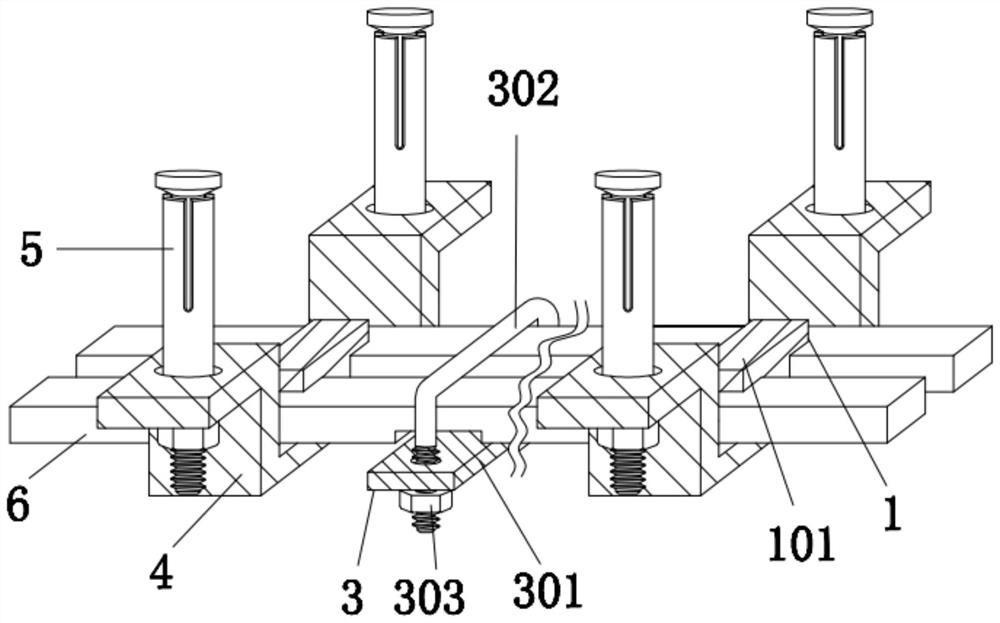

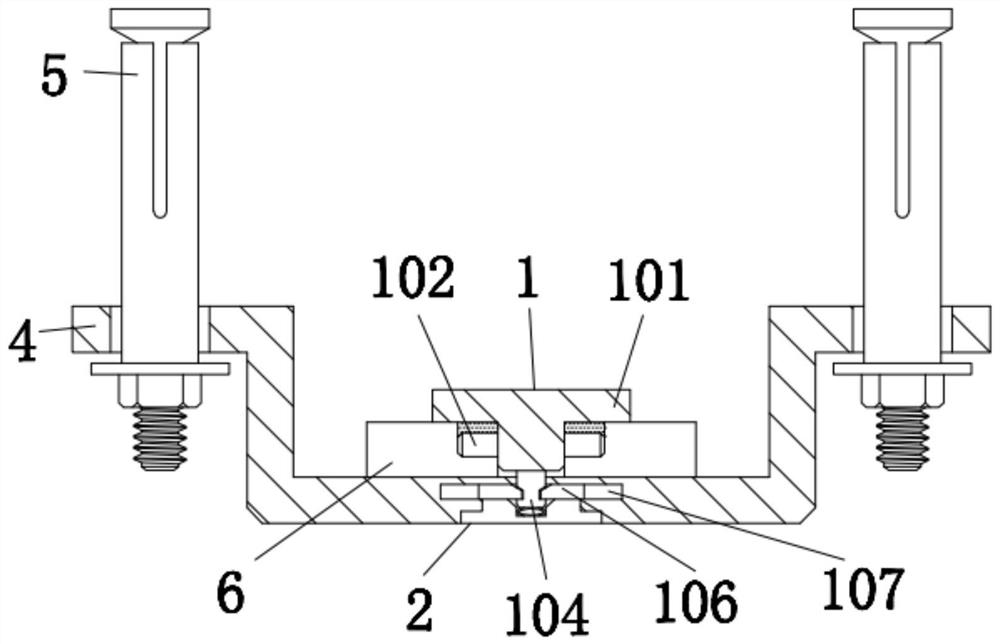

[0039] A system for reinforcing corroded steel bars for bridge reinforcement, including a U-shaped plate 4, the left and right sides of the inner wall of the U-shaped plate 4 are equipped with expansion bolts 5 in gaps, and holes are drilled inside the external bridge, and the bridge and the bridge can be connected through the expansion bolts 5 The U-shaped plate 4 is fixed at the valley, and the left and right sides of the inner wall of the U-shaped plate 4 are all provided with a square plate 6, and the square plate 6 plays a position-limiting effect on a plurality of U-shaped plates 4. The bottom of the inner wall of 4 fits together, and the square plate 6 is fixed together with the U-shaped plate 4 through the fixing device 1. The fixing device 1 includes a base 101, a short rod 102, a vertical groove 103, a pole 104, a slot 105, and a latch 106 , rubber columns 107 and transverse grooves 108, the left and right sides of the bottom of the base 101 are respectively attached ...

Embodiment 2

[0041] As an option, see figure 1 , 2, 4, 5 and 6, the corroded steel reinforcement system for bridge reinforcement, the bottom of the pole 104 is provided with a closing device 2, the closing device 2 includes a bottom plate 201, a groove 202 and a ring 203, the outer wall of the bottom plate 201 and the U-shaped plate 4 Welded together, the top of the bottom plate 201 is processed with a groove 202, the groove 202 is used to prevent the ring 203, the ring 203 gives the upward force to the pole 104 through its own deformation, and then makes the bottom of the inner wall of the card groove 105 and the latch 106 The bottom of the bottom of the groove 202 is tightly pressed, and the inner wall of the groove 202 is provided with a ring 203. The top and bottom of the ring 203 are respectively pressed against the bottom of the pole 104 and the bottom of the inner wall of the groove 202. The bottom of the bottom plate 201 is connected to the U-shaped plate 4 The bottom of the botto...

Embodiment 3

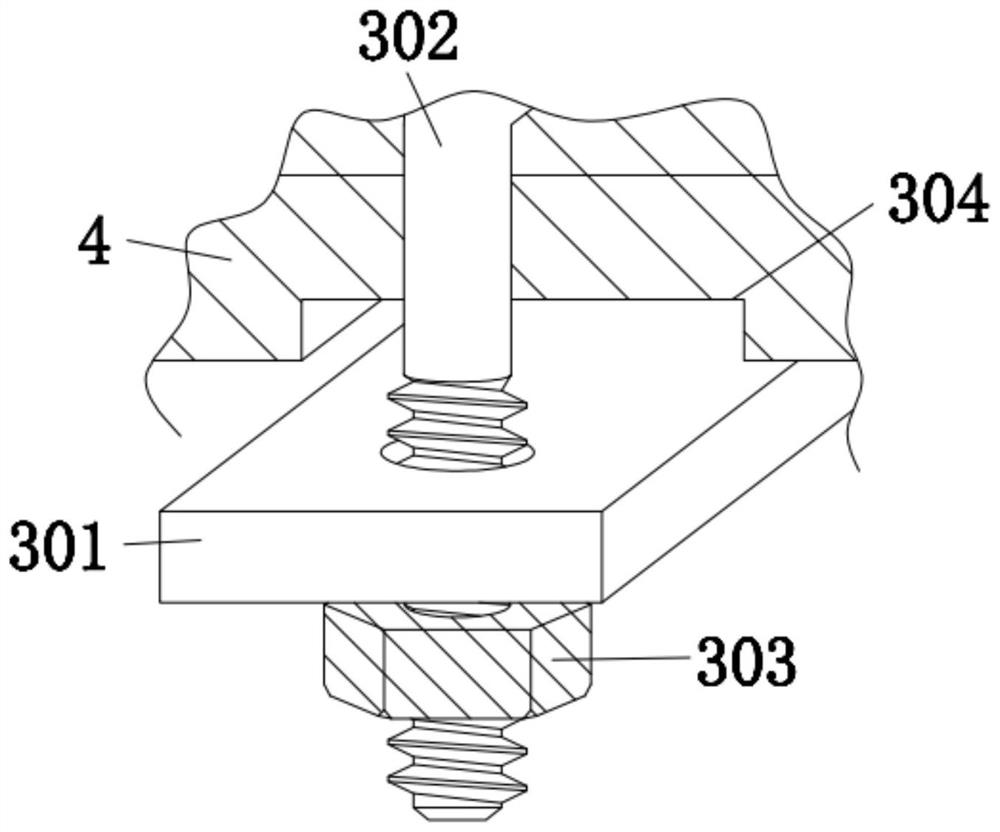

[0044] As an option, see figure 1 , and 3, the corroded steel reinforcement system for bridge reinforcement, the outer wall of the square plate 6 is provided with a clamping device 3, and the clamping device 3 includes a horizontal plate 301, a U-shaped bar 302, a nut 303 and a square groove 304, and the top of the horizontal plate 301 A U-shaped bar 302 is provided, and the two ends of the U-shaped bar 302 run through the left and right sides of the horizontal plate 301 respectively. The U-shaped bar 302 cooperates with the horizontal plate 301 to prevent the two square plates 6 from moving away from each other. Nuts 303 are threaded on the left and right sides, and the nuts 303 play a limiting role on the horizontal plate 301 and the U-shaped bar 302. The top of the nut 303 fits the bottom of the horizontal plate 301. bottom, the depth of the square groove 304 is 1 / 2 of the height of the horizontal plate 301, and the width of the square groove 304 is the same as the width of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com