Anti-skid wear-resistant split type PVC floor

A split type, floor technology, applied in the direction of floor, covering/lining, insulation, etc., can solve the problems of general anti-slip and wear resistance, easy gaps at joints, accelerated aging, etc., to increase friction and prevent The effect of increasing the gap and improving the air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

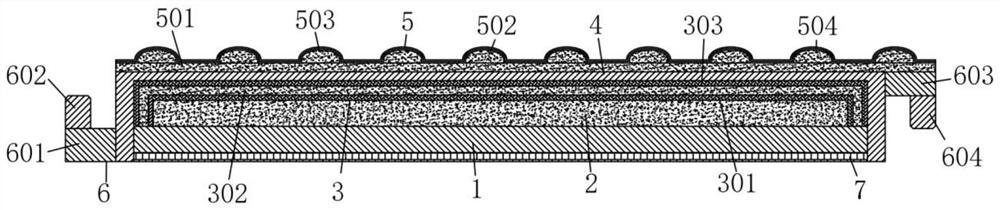

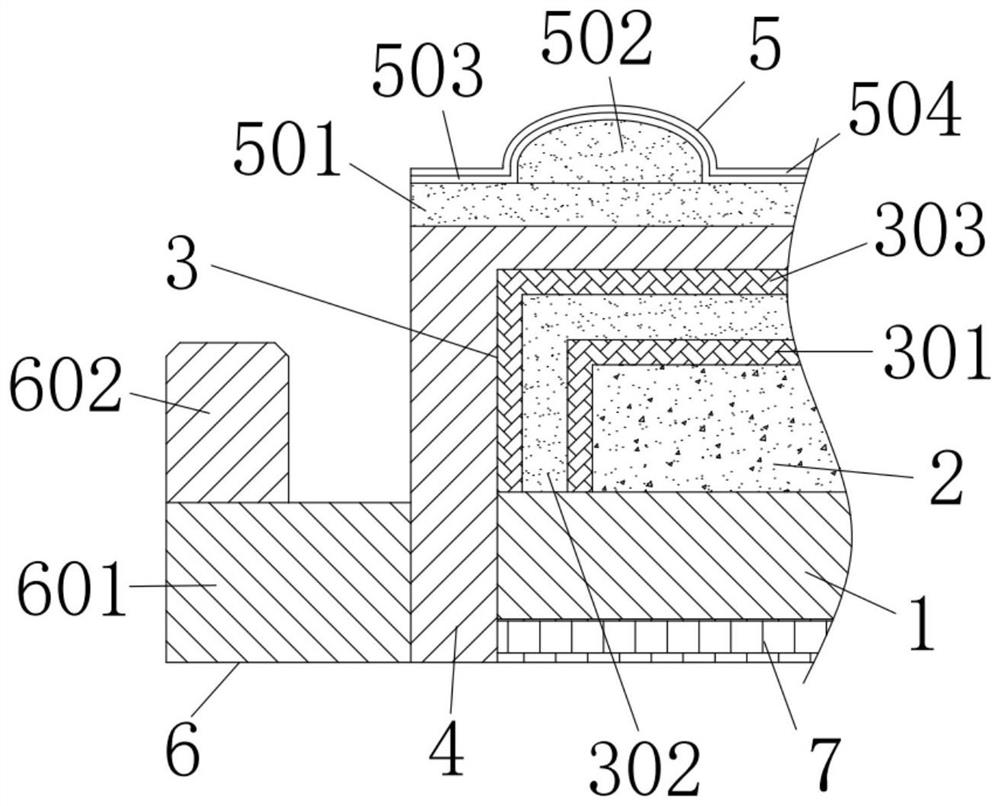

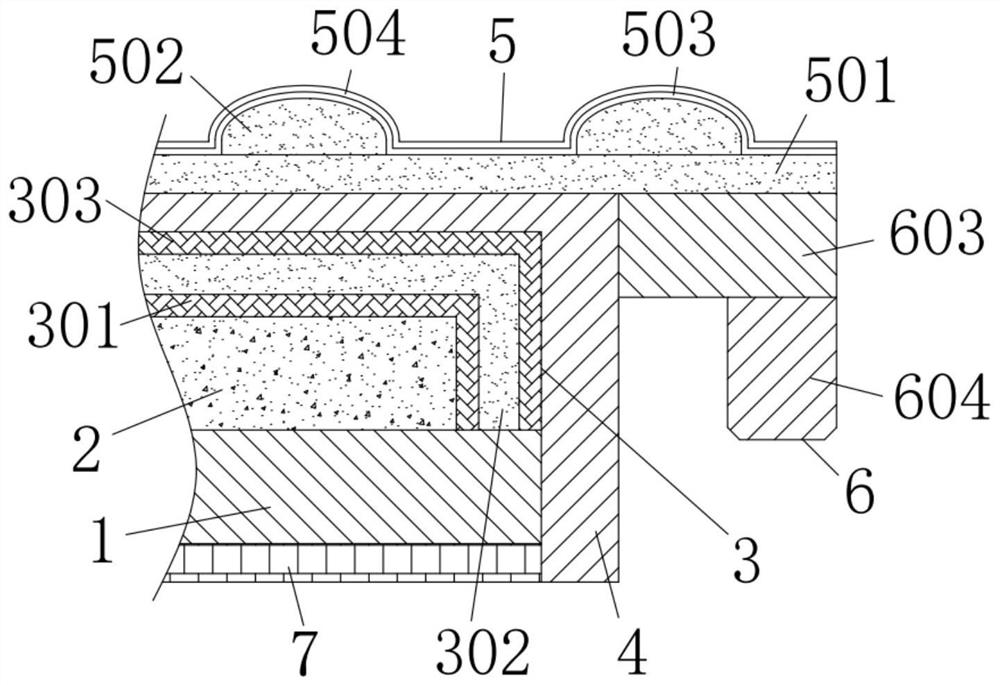

[0035] A non-slip and wear-resistant split PVC floor, comprising a PVC substrate 1, a bamboo charcoal board core 2 is arranged above the PVC substrate 1, the lower surface of the bamboo charcoal board core 2 is closely attached to the upper surface of the PVC substrate 1, and the bamboo charcoal board core is The lower surface of the body 2 is affixed to the upper surface of the PVC substrate 1, and the outer side of the bamboo charcoal plate core body 2 is provided with a waterproof layer 3, and the inner wall of the waterproof layer 3 is socketed with the outer wall of the bamboo charcoal plate core body 2, and the waterproof layer 3 The inner wall is affixed to the outer wall of the bamboo charcoal board core 2, the lower surface of the waterproof layer 3 is attached to the upper surface of the PVC substrate 1, and the lower surface of the waterproof layer 3 is affixed to the upper surface of the PVC substrate 1; the waterproof layer 3 Including a first stable layer 301, a w...

Embodiment 2

[0039] When the overall mechanism is laid, the connection between the two adjacent integral mechanisms is realized by the first clamping block 602 and the second clamping block 604, so as to prevent the gap from widening after long-term use, thereby delaying the aging speed. During normal use, the bump 502 on the top can greatly increase the frictional force, thereby effectively improving the frictional force, thereby achieving the purpose of anti-skid, and the air around the whole mechanism will pass through the buffer layer 501 and the PVC substrate 1, And remove moisture under the effect of water barrier layer 302, the air after removing moisture contacts with bamboo charcoal plate core body 2, because the self characteristic of bamboo charcoal plate core body 2, thereby air is sterilized, and then improves air quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com