an integrated stove

An integrated stove and stove shell technology, applied in the field of integrated stoves, can solve problems such as high temperature of the stove chassis, potential safety hazards of electrical components such as controllers, poor treatment effect of oil fume or steam, etc., so as to improve the efficiency of external discharge and avoid diffuse condensation , reduce the effect of condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

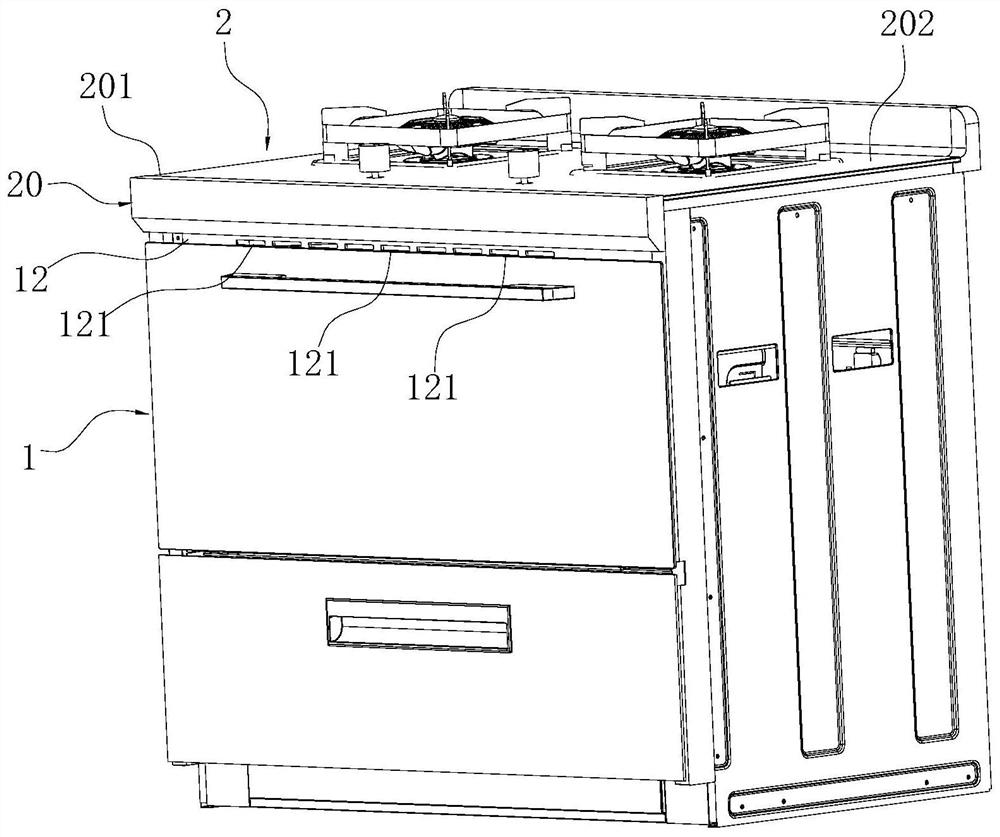

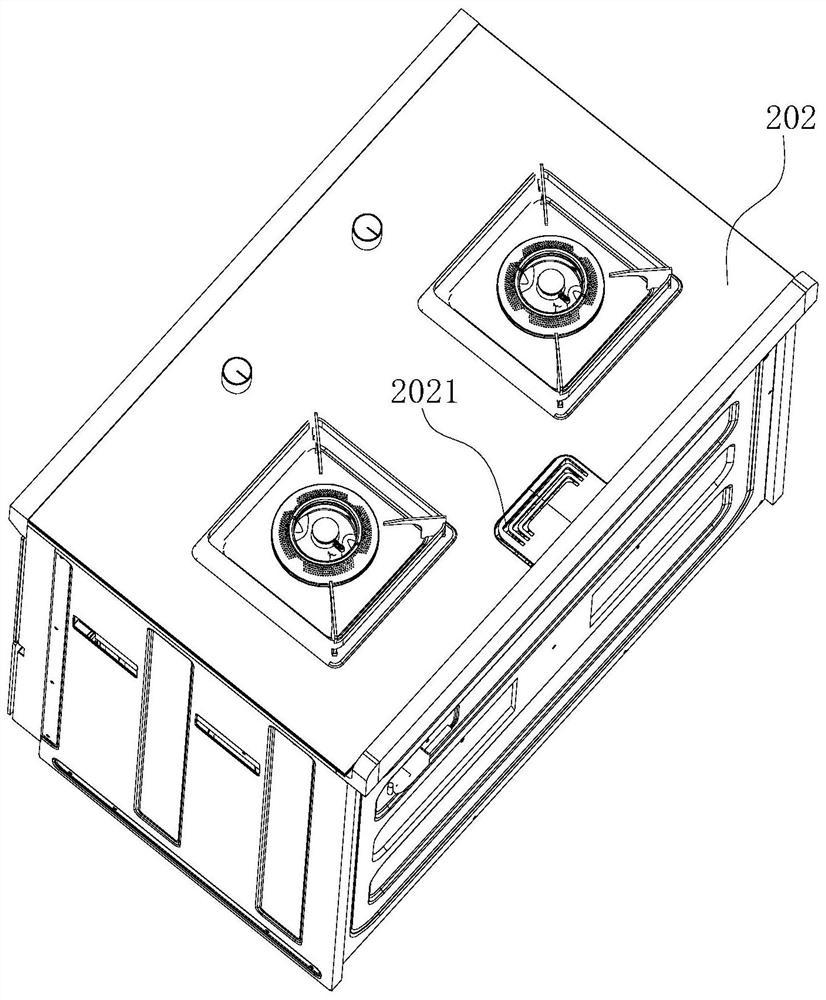

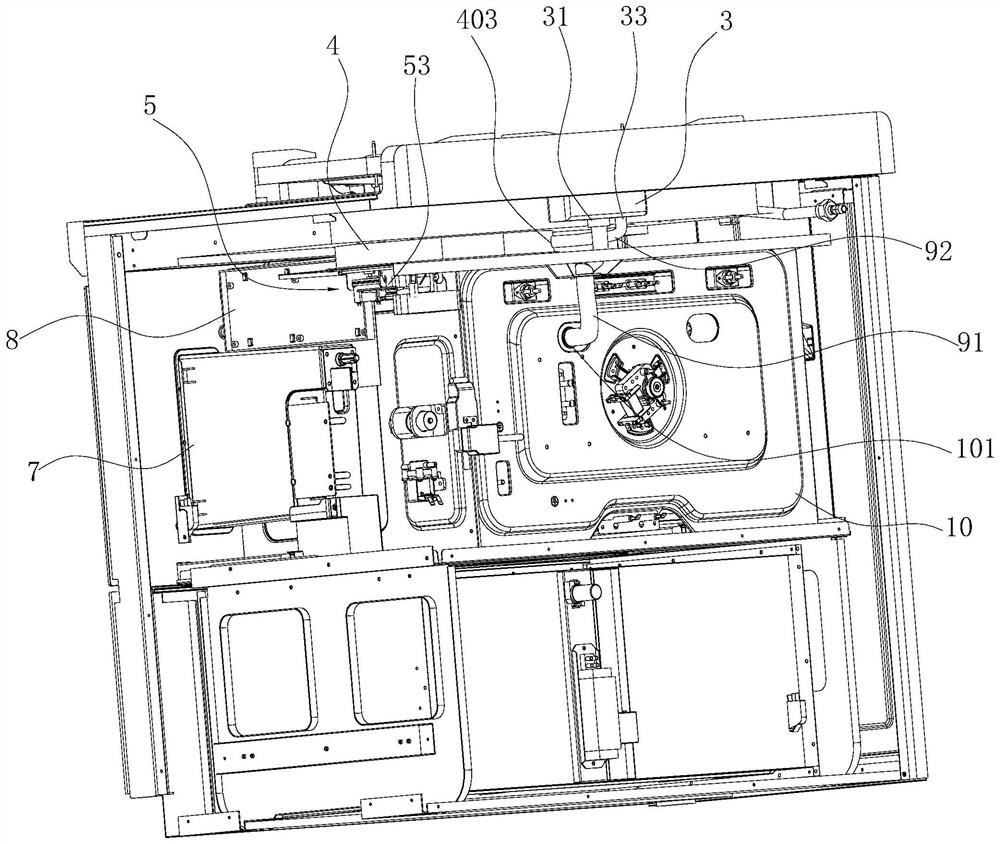

[0030] like Figures 1 to 11 As shown, an integrated cooker includes a cooking device 1 and a cooker 2 disposed on the cooking device 1. In this embodiment, the cooking device 1 has a steaming function, such as a steam box or an integrated steamer and oven. The above-mentioned cooking device 1 has an inner container 10 with a front opening, and the front opening of the inner container 10 is covered with a door body 11. The above-mentioned stove shell 20 includes a chassis 201 and a panel 202 that covers the opening of the chassis 201. The panel 202 is provided with a second exhaust port 2021, and the air inlet 31 of the above-mentioned exhaust chamber 30 is in fluid communication with the first exhaust port 101 on the above-mentioned liner 10 (the fluid communication here has various specific Implementation method: when the air inlet 31 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com