Manufacturing and positioning device and method for vertical stabilization wallboard stability test piece

A stability test and vertical stability technology, applied in the field of manufacturing positioning devices, can solve the problems that it is difficult to ensure the relative position of the composite wall plate and the steel hoop, cannot meet the quality requirements of the test piece, cannot meet the mass production, etc., and achieve good practical value , manpower saving and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

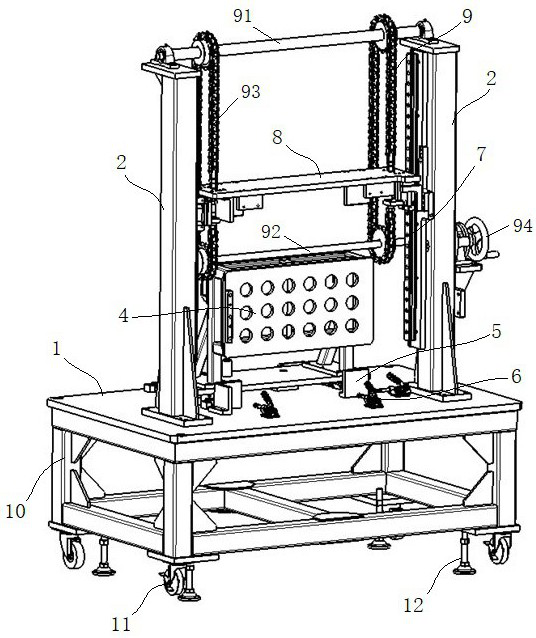

[0028] The technical solutions of the present invention will be clearly and completely described below with reference to the embodiments and the accompanying drawings. Obviously, the described embodiments are only the preferred embodiments of the present invention, not all the embodiments, nor are they intended to be used for the present invention. Any other form of limitation, any person skilled in the art may use the disclosed technical content to make changes or modifications and equivalent changes. However, any simple modifications, equivalent changes and modifications made to the above embodiments according to the technical essence of the present invention without departing from the content of the technical solutions of the present invention still belong to the protection scope of the technical solutions of the present invention. Examples are as follows:

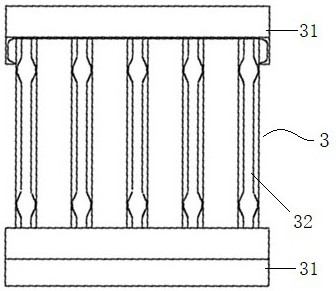

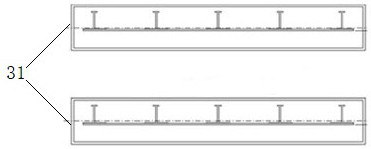

[0029] A manufacturing and positioning device for the stability test piece of a vertical stabilizer wall plate, such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com