Wafer cleaning device

A technology for cleaning wafers and cleaning tanks, applied in cleaning methods and appliances, cleaning methods using liquids, electrical components, etc., can solve problems such as cost sensing and correction, lower production efficiency, and leakage of cleaning solutions to ensure safety , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, embodiments will be described in detail with reference to the accompanying drawings. However, the scope of the spirit of the present invention can be determined from the matters disclosed in the embodiments, and the spirit of the embodiments of the present invention includes actual modifications to the embodiments presented below, such as addition, deletion, modification, etc. of components.

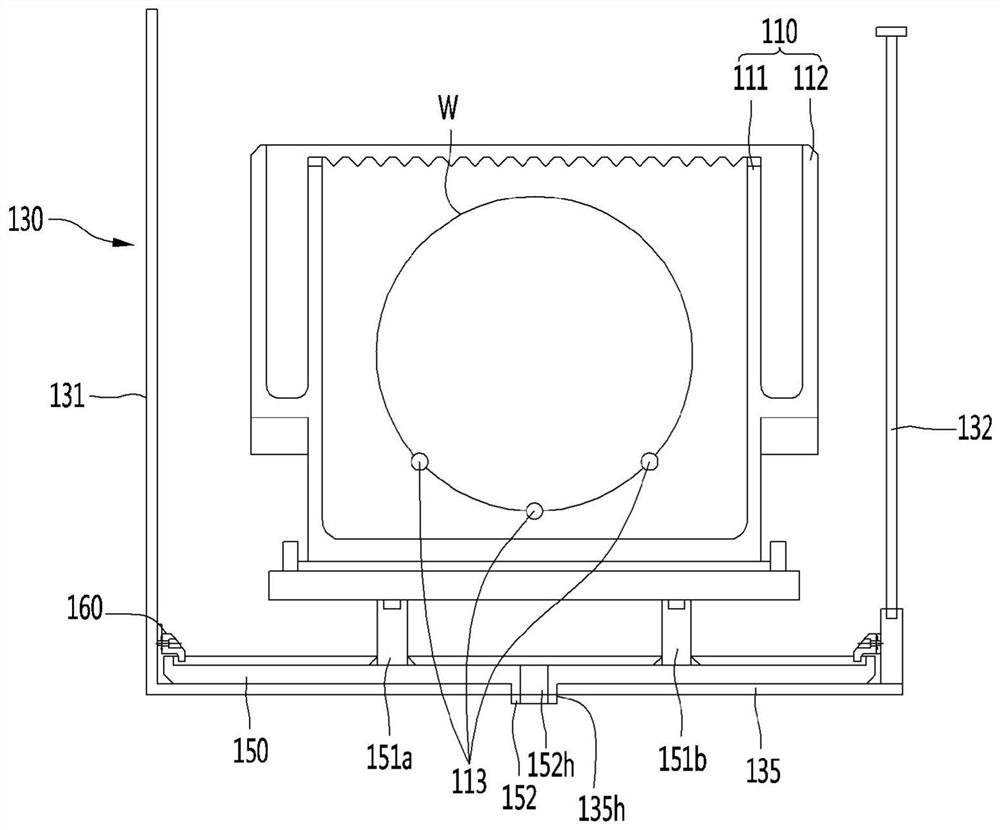

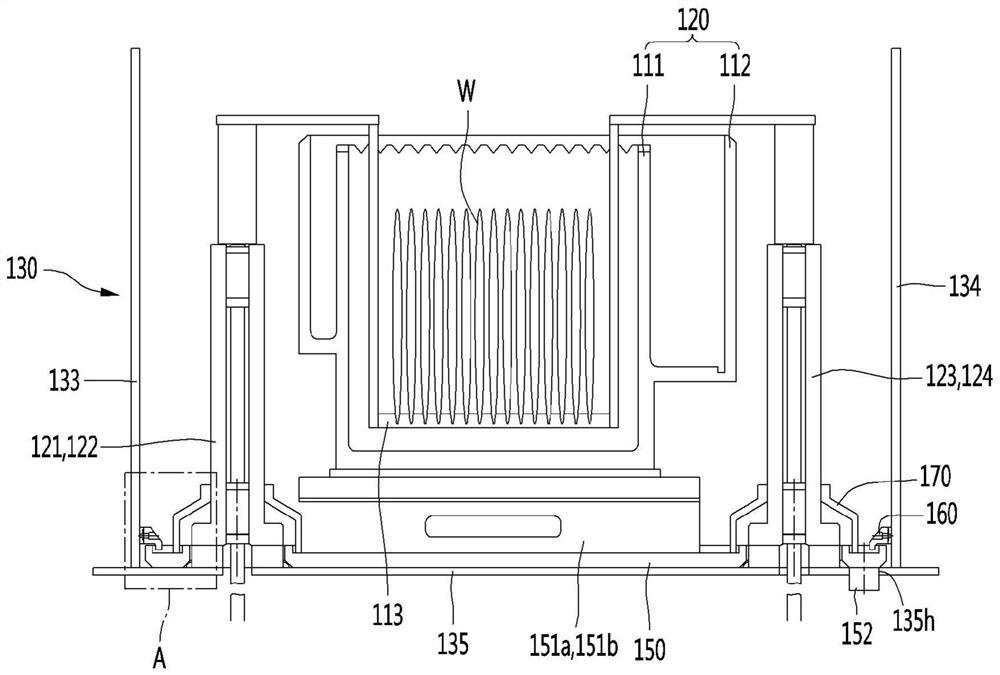

[0031] figure 1 and figure 2 are a front view and a side view showing a wafer cleaning apparatus according to the present invention.

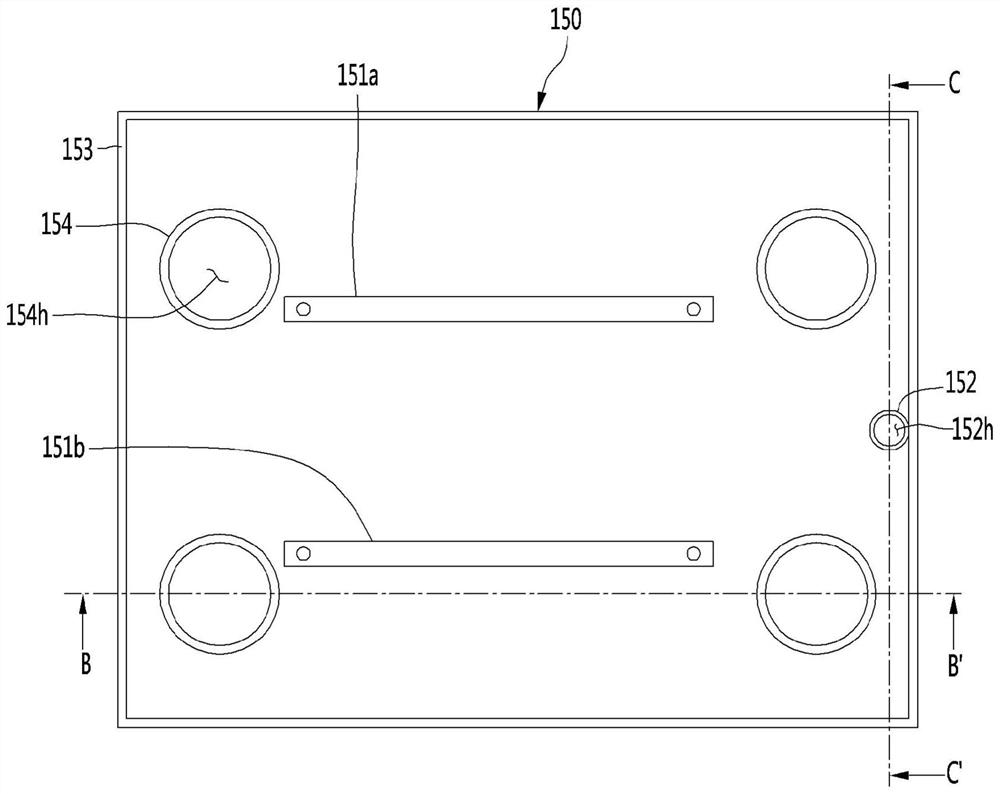

[0032] In the wafer cleaning device according to the present invention, such as figure 1 and figure 2 As shown, the cleaning tank 110 and the four lifting parts 121, 122, 123 and 124 are arranged in the external water tank 130, the tray 150 for collecting and discharging the cleaning solution is arranged in the external water tank 130, and provides a The cleaning solution is guided to the first guide part 160 and the second guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com