Nut conveying and positioning method for nut riveting

A positioning method and technology of riveting and pressing screws, which is applied in the field of riveting presses, can solve problems such as inaccurate positioning of nuts, and achieve the effects of reducing friction, smooth movement, and accurate position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

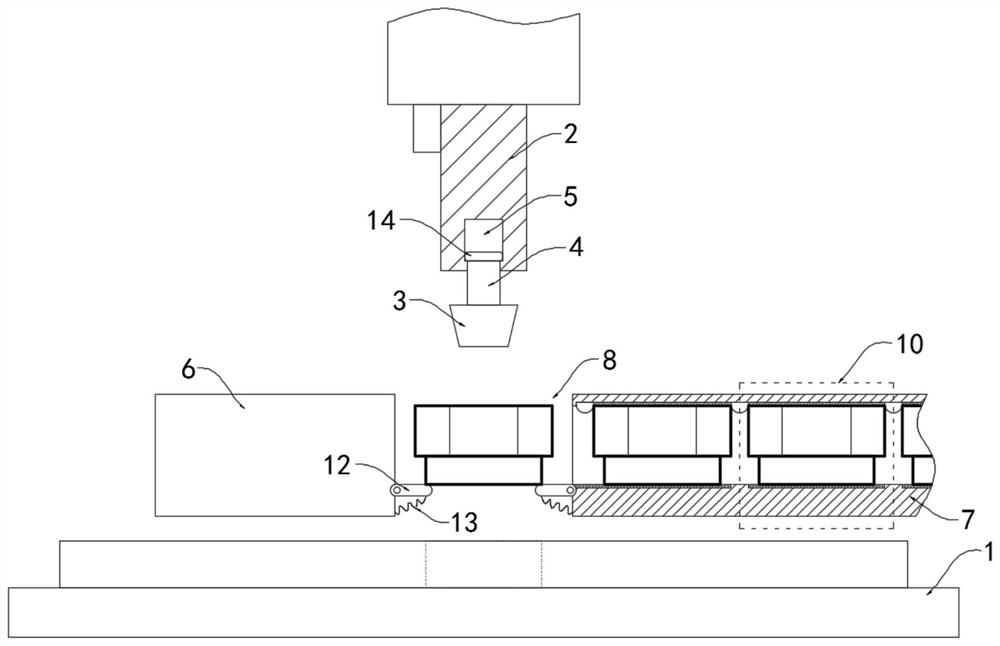

[0028] like Figure 1-2 As shown, a nut delivery and positioning method of a riveting nut, the specific delivery and positioning method is as follows:

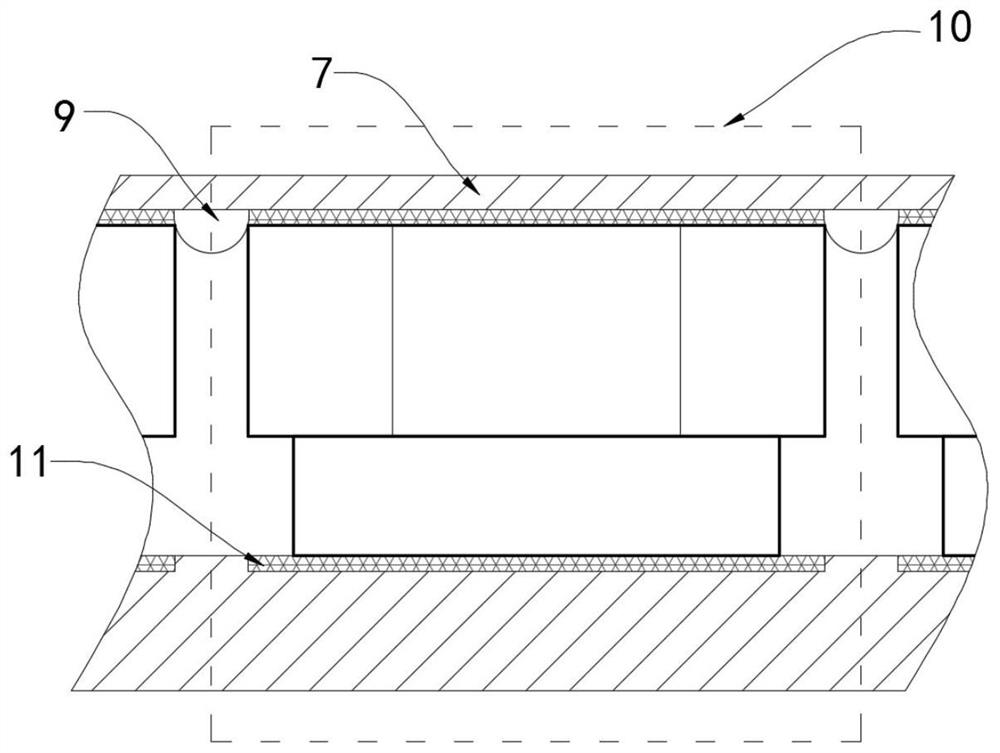

[0029] S1, feeding, put a plurality of nuts into the delivery cylinder 7 in sequence, each nut is placed in a conductive unit 10 and forms a conductive circuit with the conductive plates 11 on the upper and lower side walls of the conductive unit 10;

[0030] S2, conveying, when the magnetic positioning block 3 is close to the port of the delivery cylinder 7, the nut will move into the positioning port 8 under the common gravitational force of the magnetic positioning block 3 and the magnetic fixing block 6;

[0031] S3, positioning, the riveting head 2 moves downward for a certain distance, the magnetic positioning block 3 at its lower end will first contact the nut, and when the nut position is accurate, the magnetic fixing block 6 will smoothly enter the through hole of the nut;

[0032] S4, riveting, after the positioning...

Embodiment 2

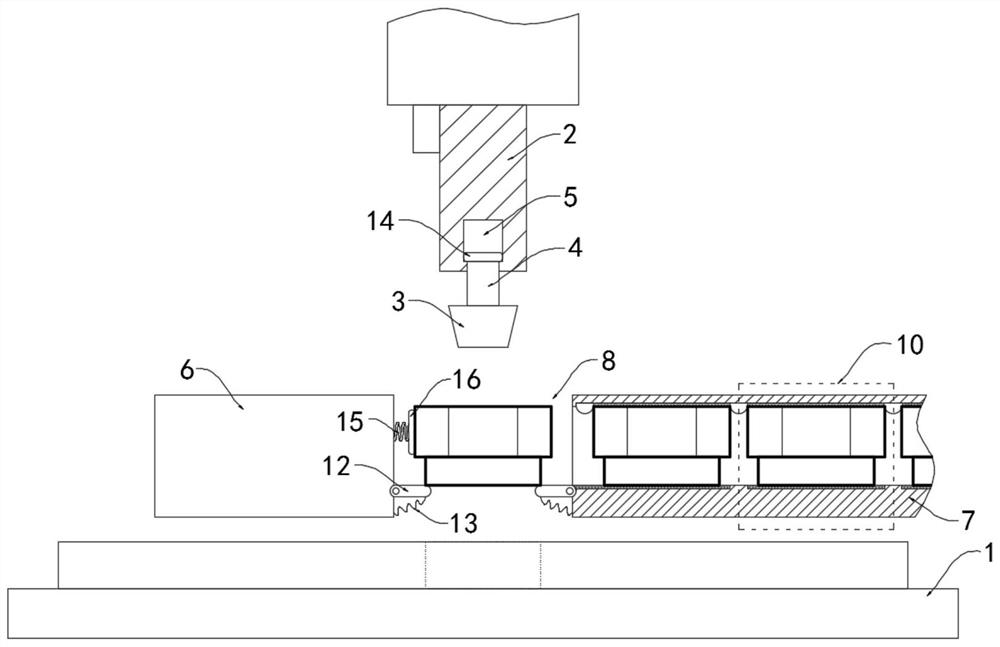

[0047] like Figure 3-4 As shown, the difference between this embodiment and Embodiment 1 is that the side wall of the magnetic fixing block 6 located in the positioning opening 8 is fixedly connected with the positioning plate 16 through the induction coil 15. It is worth mentioning that the inner side of the delivery cylinder 7 A plurality of rollers 17 are fixedly installed on the wall.

[0048] In this embodiment, when the nut moves to the positioning port 8 under the gravitational force of the magnetic positioning block 3 and the magnetic fixing block 6, since the nut is electrified at this time and has magnetism, it can be known from Lenz's law that the magnetic field of the induced current always Blocking the change of the magnetic flux that causes the induced current, the magnetic nut will decelerate under the repulsion of the induction coil 15 when it is close to the induction coil 15, which can prevent the nut from colliding with the positioning plate 16 at a relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com