Preparation process of microcluster water

A technology of small molecular mass water and preparation technology, applied in the field of small molecular mass water preparation technology, can solve the problems of limited water resources of small molecular mass, and achieve the effect of auxiliary treatment of various diseases, strong osmotic power and metabolism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A process for preparing small water clusters includes the following steps:

[0027] (1) Put the nano functional ceramic ball into the reaction kettle; pour pure water into the reaction kettle and soak for 8 hours;

[0028] (2) Heat the reaction kettle to 160°C, pressurize it to 5 atmospheres, maintain the temperature and pressure in the kettle for 20 minutes, then cool down and exhaust until the temperature in the kettle drops to 25°C, and the pressure drops to 0;

[0029] (3) Repeat step (2) three times;

[0030] (4) After the water in the reaction kettle is cooled, the water is pumped into a magnetized rod container containing 100,000 Gauss for 7 hours, then filtered, sterilized, and collected.

[0031] In this embodiment, the ratio of the nano-ceramic ball to the purified water in step (1) is: 1 nano-ceramic ball corresponds to 200 mL of purified water.

[0032] In this embodiment, the raw material of the nano functional ceramic ball is composed of the following components by w...

Embodiment 2

[0037] A process for preparing small water clusters includes the following steps:

[0038] (1) Put the nano functional ceramic ball into the reaction kettle; pour pure water into the reaction kettle and soak for 6 hours;

[0039] (2) Heat the reaction kettle to 145°C, pressurize it to 4 atmospheres, maintain the temperature and pressure in the kettle for 15 minutes, then cool and exhaust until the temperature in the kettle drops to 22.5°C and the pressure drops to 0;

[0040] (3) Repeat step (2) three times;

[0041] (4) After the water in the reaction kettle is cooled, the water is pumped into a magnetized rod container with 100,000 Gauss for 6 hours, then filtered, sterilized, and collected.

[0042] In this embodiment, the ratio of the nano-ceramic balls to the purified water in step (1) is: 1 nano-ceramic ball corresponds to 190 mL of purified water.

[0043] In this embodiment, the raw material of the nano functional ceramic ball is composed of the following components by weight: Si...

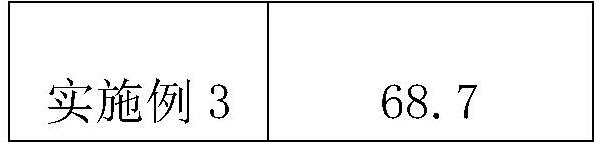

Embodiment 3

[0048] A preparation process of small molecular cluster water includes the following steps:

[0049] (1) Put the nano functional ceramic ball into the reaction kettle; pour pure water into the reaction kettle and soak for 4 hours;

[0050] (2) Heat the reaction kettle to 130°C, pressurize it to 3 atmospheres, maintain the temperature and pressure in the kettle for 10 minutes, then cool down and exhaust until the temperature in the kettle drops to 20°C, and the pressure drops to 0;

[0051] (3) Repeat step (2) three times;

[0052] (4) After the water in the reaction kettle is cooled, the water is pumped into a magnetized rod container with 100,000 Gauss for 5 hours, then filtered, sterilized, and collected.

[0053] In this embodiment, the ratio of the nano-ceramic ball to the purified water in step (1) is: 1 nano-ceramic ball corresponds to 180-200 mL of purified water.

[0054] In this embodiment, the raw material of the nano functional ceramic ball is composed of the following compone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com