Collapsible type foundation grouting material solidification reinforcing structure

A technology of grouting material and reinforced structure, which is applied in basic structure engineering, soil protection, construction, etc. It can solve the problems of easy collapsibility and insufficient bearing capacity of the foundation, so as to eliminate settlement deformation, increase bearing capacity, and improve land quality. The effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

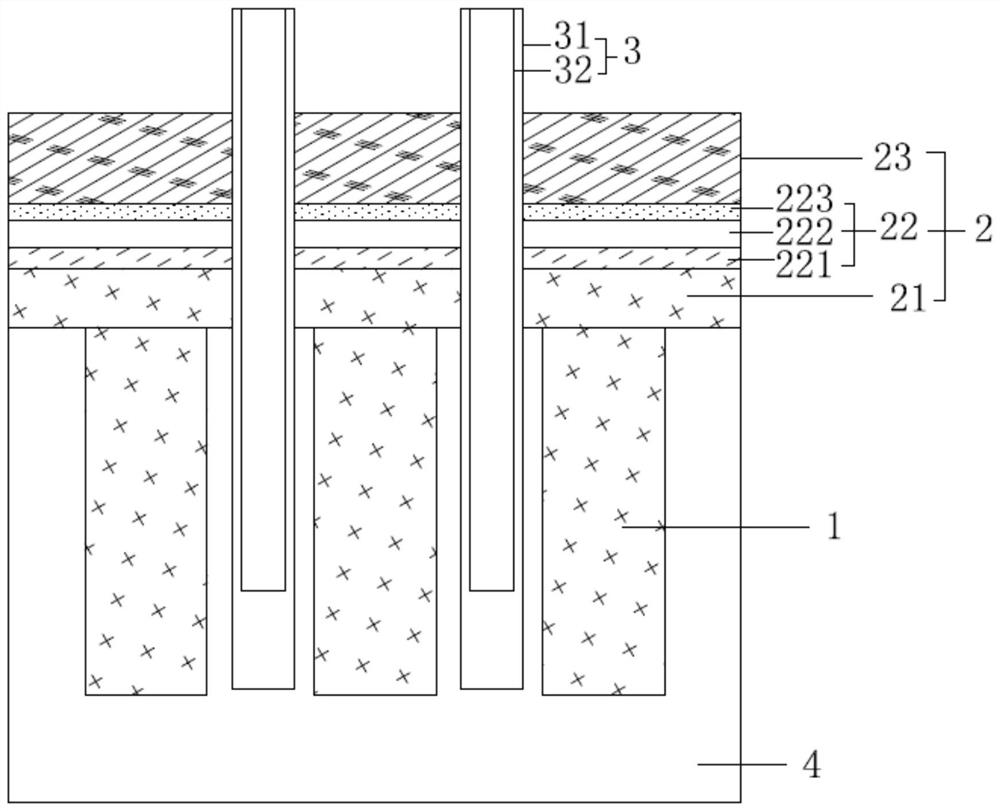

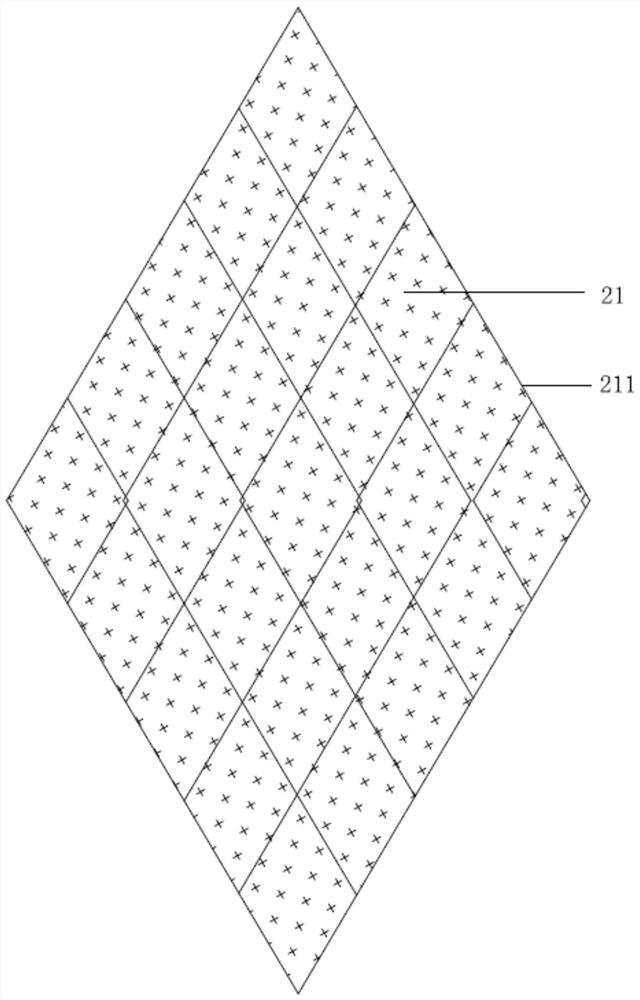

[0021] See figure 1 with figure 2 , The figure shows a collapsible foundation grouting material curing reinforcement structure provided in the first embodiment of the present invention, including gravel pile 1, foundation layer 2 and drainage device 3, gravel pile 1 extends longitudinally into the to be reinforced In the loess layer 4, multiple gravel piles 1 are arranged in a grid pattern, and the foundation layer 2 is sequentially provided with a geocell gravel layer 21, a waterproof layer 22, and a concrete surface layer 23 from bottom to top. The cell crushed stone layer 21 is combined with water glass grouting through a pre-embedded grouting pipe to form a whole. The drainage device 3 penetrates the foundation layer 2 and the bottom of the drainage device 3 extends into the loess layer 4.

[0022] Specifically, see figure 1 with figure 2 , The drainage device 3 and the gravel pile are arranged in parallel.

[0023] Specifically, see figure 1 with figure 2 The drainage de...

Embodiment 2

[0031] See figure 1 with figure 2 , The figure shows a collapsible foundation grouting material curing reinforcement structure provided by the second embodiment of the present invention. On the basis of the above-mentioned embodiment, this embodiment further makes the following as an improved technical solution: water Glass grouting components include isocyanate, active toughening agent and trimerization catalyst; water glass grouting includes the following components by weight percentage: water glass 46.6%, isocyanate 41.4%, active toughening agent 10.4%, trimerization catalyst 1.6%.

[0032] The water glass grouting enters the loess layer when the gravel pile and the geocell gravel layer are grouted, and strengthens the loess layer through consolidation. The water glass grouting ingredients include isocyanate, active toughening agent and trimerization catalyst. Specifically, 90 parts of water glass, 80 parts of isocyanate (MDI), 20 parts of active toughening agent and 3 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com