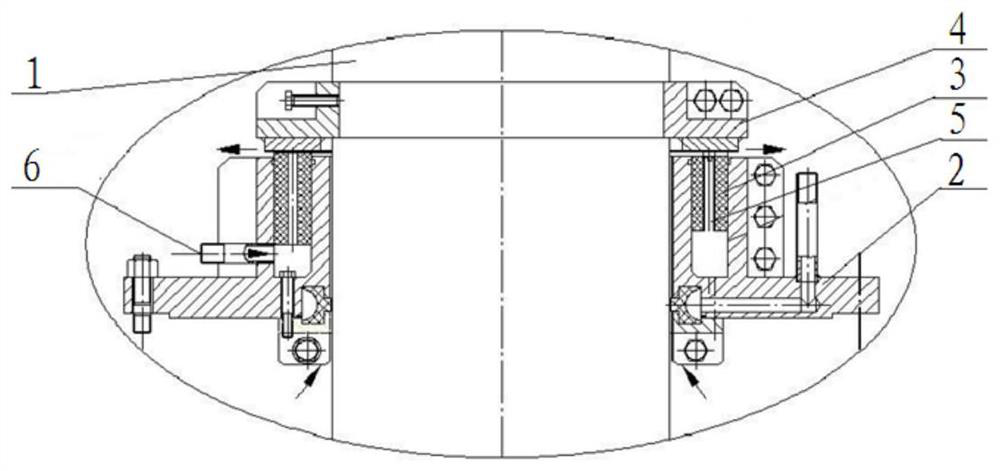

Filtering and pressure stabilizing system for main shaft sealing water of hydropower station unit

A spindle seal and hydropower station technology, applied in engine seals, filter separation, piping systems, etc., can solve the problems of spindle 1 seal failure, frequent replacement of leak-proof sealing devices, and increased equipment use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

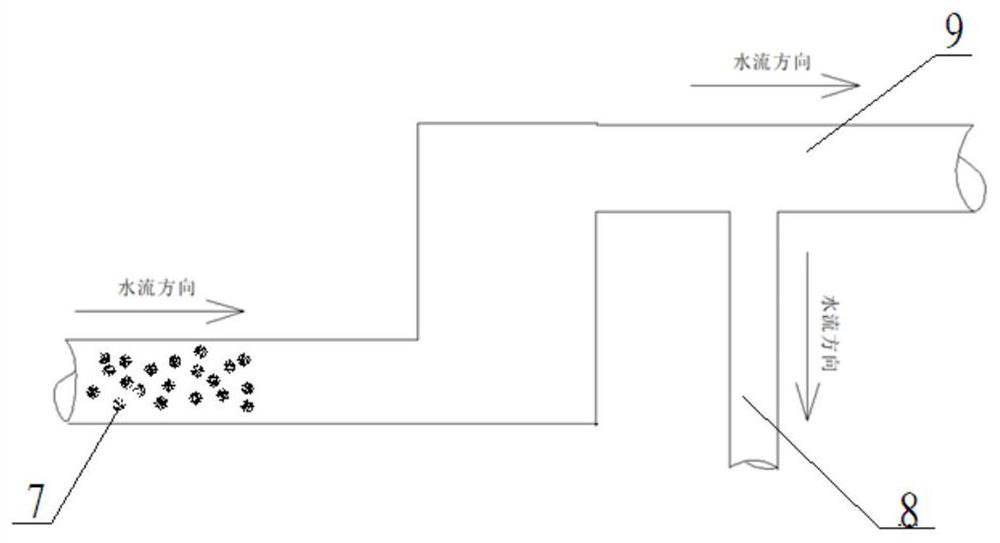

Problems solved by technology

Method used

Image

Examples

Embodiment 1

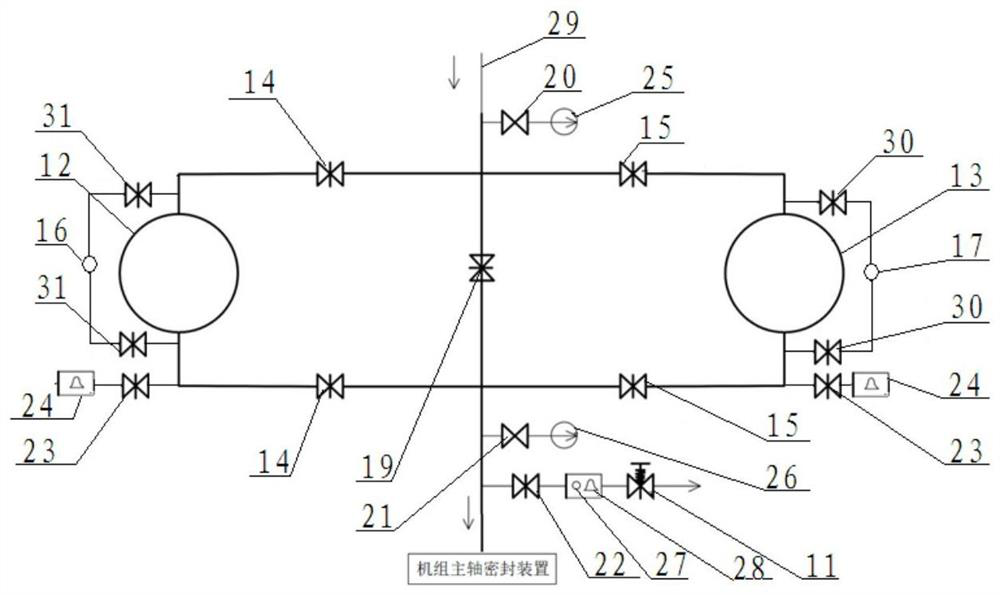

[0024] See image 3 , Figure 4 Shown: The present invention is a filtering and stabilizing system for the main shaft sealing water of a hydropower station. The main shaft sealing water is transported through the main shaft sealing water main pipe 29 (it is the existing mature technology, and the main shaft sealing water main pipe 29 is the main water supply pipeline for the unit technology. That is, the input end of the main shaft sealing water main pipe 29 for conveying the main shaft sealing water is connected to the main technical water supply pipeline of the unit, and then the output end of the main shaft sealing water main pipe 29 is directly connected to the main shaft sealing device of the unit, which is the main shaft sealing device. The device provides spindle sealing water.),

[0025] The filtering and voltage stabilizing system includes a voltage stabilizing device and a filter device. A voltage stabilizing device is provided on the main shaft sealing water main pipe ...

Embodiment 2

[0045] The other structure of the second embodiment is the same as that of the first embodiment. The difference is that the first filter device and the second filter device are connected in parallel, and the formed parallel unit is connected in series with the main shaft sealing water main pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com