Novel prefabricated rail top air duct suitable for subway station

A technology for rail-top air ducts and subway stations, which is applied in pipeline layout, pipeline supports, mechanical equipment, etc. It can solve the problems of not considering professional interfaces, complicated construction procedures, and difficult to guarantee construction quality, and reduce the overall number of components and formwork. model, improve the integrity and look and feel quality, and facilitate the effect of mass production and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

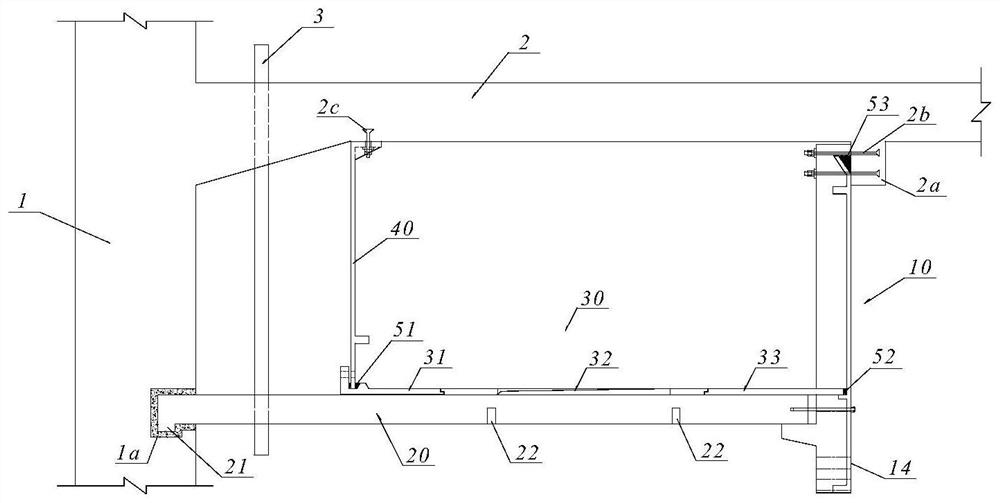

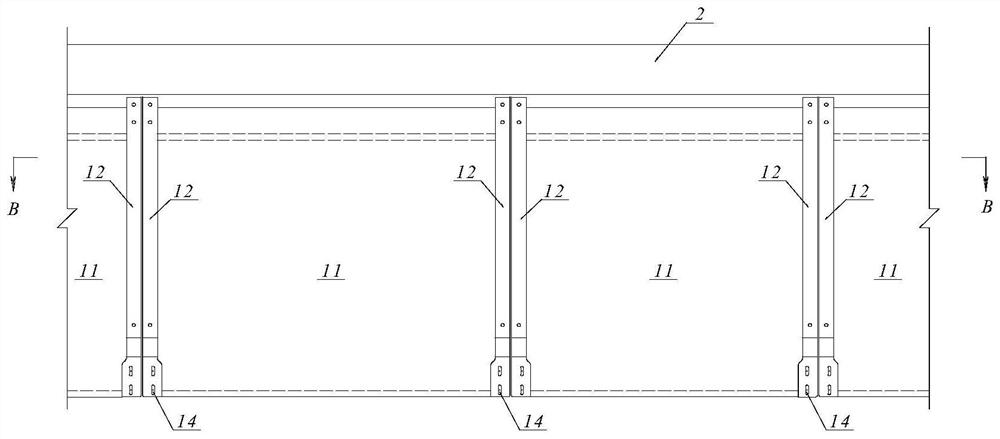

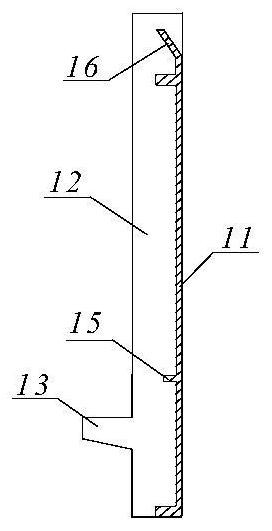

[0034] refer to figure 1 , a new type of prefabricated rail top air duct suitable for subway stations according to the present invention. The rail top air duct is formed by longitudinal butt joints of prefabricated air duct segments, and each prefabricated air duct segment forms a fixed connection with the station side wall 1 and the station middle plate 2 . The prefabricated air duct segments are assembled from side plate components 10 , cross beam components 20 , bottom plate components 30 and inner plate components 40 . The lateral sides of the side plate member 10 have vertically extending side plate columns 12, and the upper ends of the side plate columns 12 are fixed to the middle plate longitudinal beams 2a protruding downward from the bottom surface of the station middle plate 2 through the first embedded connecting member 2b. connect. The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com