Motorized construction machine

A kind of construction machinery and motorized technology, which is applied in the direction of magnetic separation, solid separation, smoke and dust removal, etc., and can solve problems such as rust, affecting use, and damage to the roller surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] as attached figure 1 to attach Figure 5 Shown:

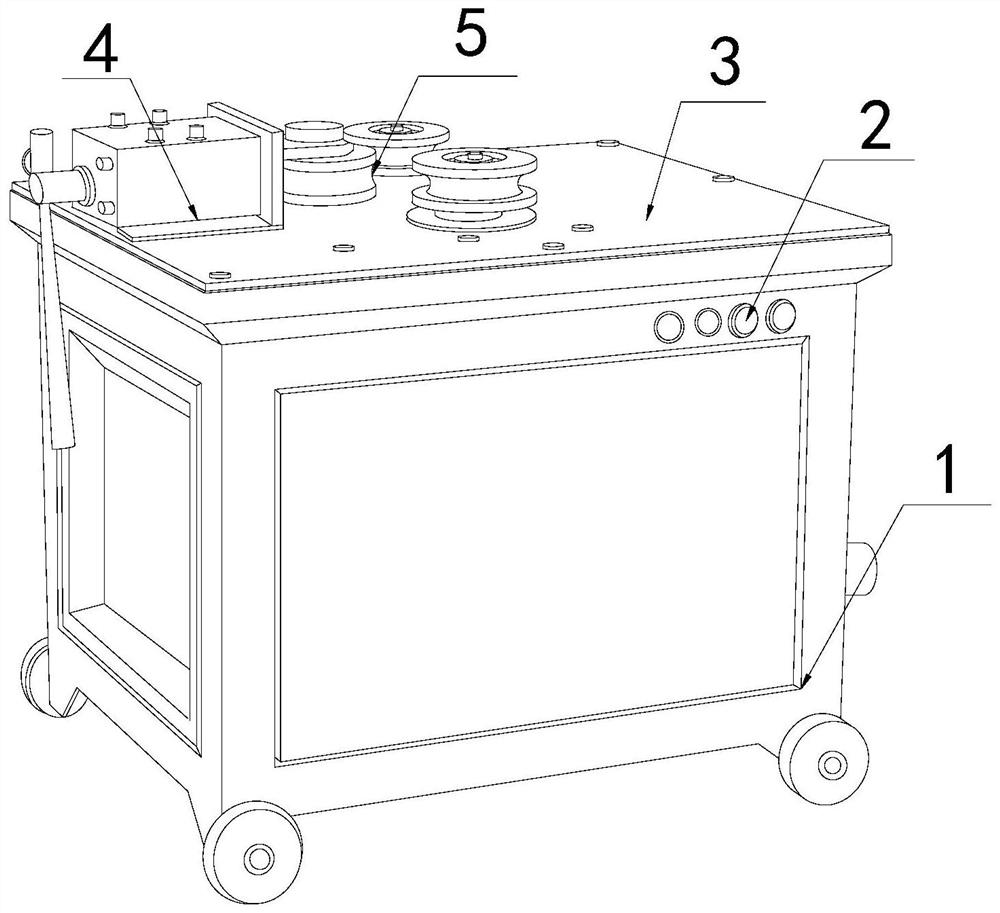

[0026] The invention provides a mobile construction machine, the structure of which includes a body 1, a button 2, a workbench 3, a telescopic table 4, and an arc bending roller 5. The button 2 is installed on the front of the body 1, and the workbench 3 is fixed on the body 1. At the top, the arc bending roller 5 is movably engaged with the top of the workbench 3 , and the telescopic table 4 is connected with the top of the workbench 3 by bolts, and is movably matched with the arc bend roller 5 .

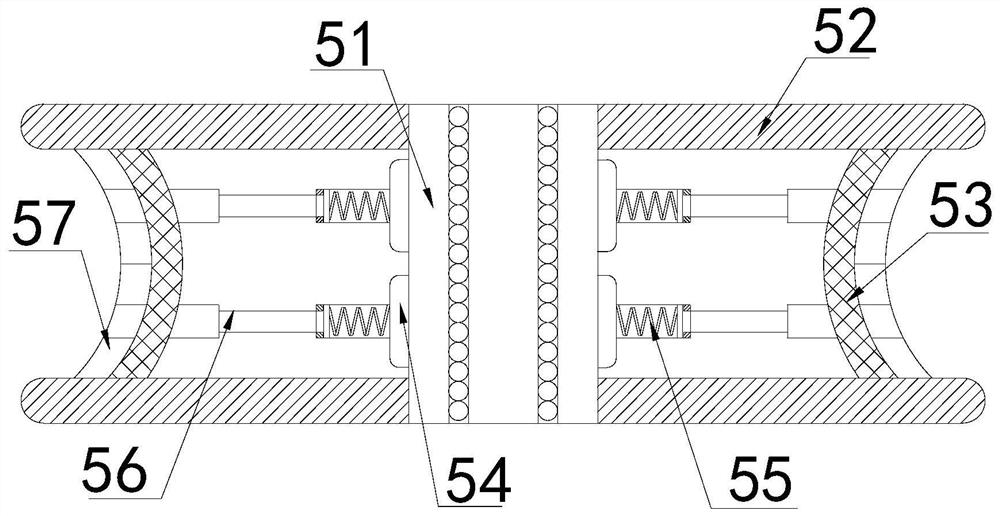

[0027] The arc bending roller 5 is provided with a bearing 51, clamping plate 52, side plate 53, base 54, spring 55, support rod 56, buffer block 57, and the bearing 51 runs through the middle part of the arc bending roller 5, and the clamping plate 52 The upper and lower ends of the arc bending roller 5 are respectively fixed, the side plates 53 are nested between the clamping plates 52, the base 54 is installed on both si...

Embodiment 2

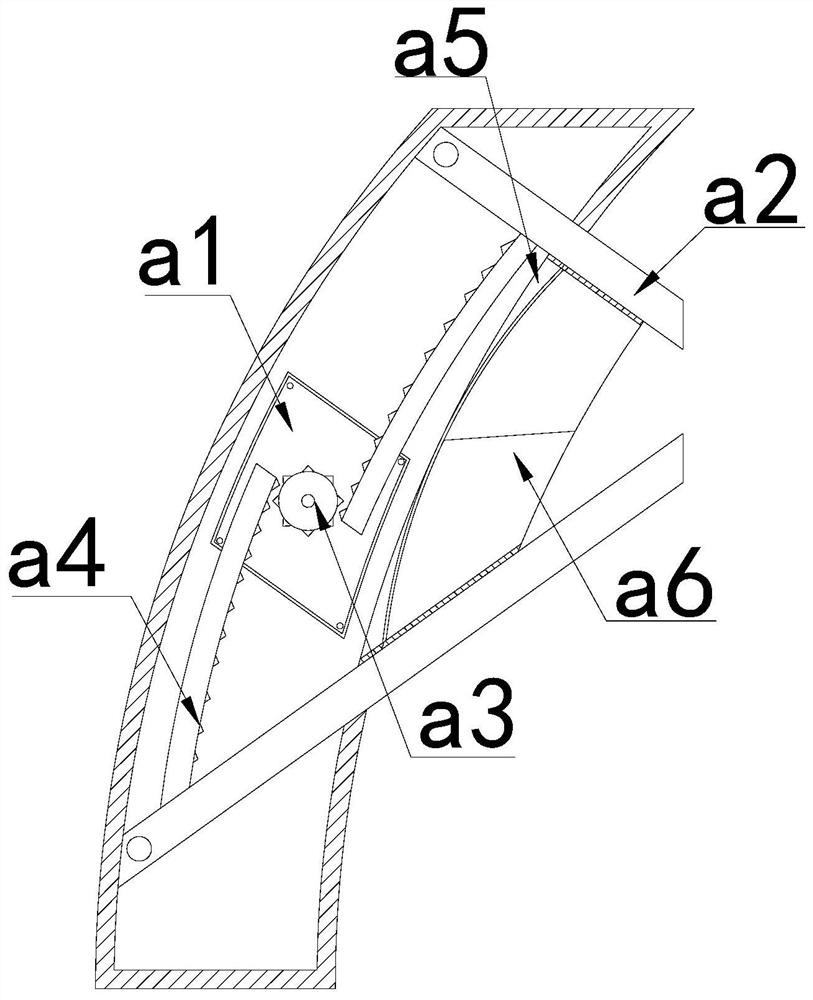

[0034] as attached Image 6 to attach Figure 7 Shown:

[0035]Wherein, the rotating rod b2 is provided with a groove d1, a return spring d2, a clamping tooth d3, a chip inlet d4, a chip collecting chamber d5, and a magnetic block d6. The groove d1 is recessed on the surface of the rotating rod b2, and the clamping Teeth d3 are movably engaged with the inner wall of the groove d1 through the return spring d2, the chip inlet d4 is recessed on the surface of the rotating rod b2 between the grooves d1, the chip collecting chamber d5 is located inside the rotating rod b2, and The chip mouth d4 is connected with each other, the magnetic block d6 is fixed at the center position inside the rotating rod b2, and there are six locking teeth d3 in total, which are evenly distributed on the surface of the rotating rod b2, which is beneficial to engage with the cutout of the steel bar and make the cutout The waste debris on the surface is brushed away, and the magnetic block d6 has a rou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com