Bulb cleaning type mounting equipment for mine ceiling lamp

A technology for installing equipment and light bulbs, which is applied in the field of clean installation equipment for light bulbs used in mine chandeliers. It can solve the problems of high mine tunnels, accumulation, and difficulty in replacement, and achieve the effect of preventing dust from flying and falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

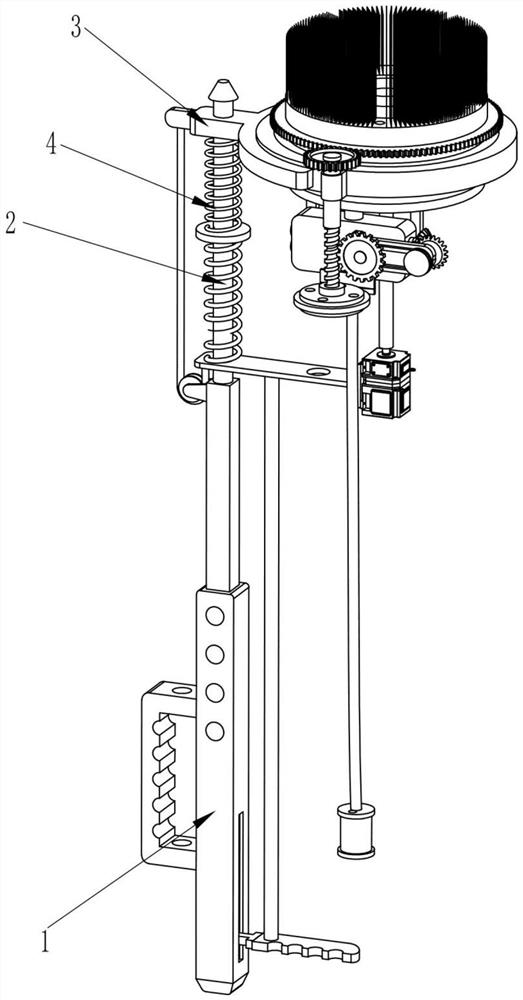

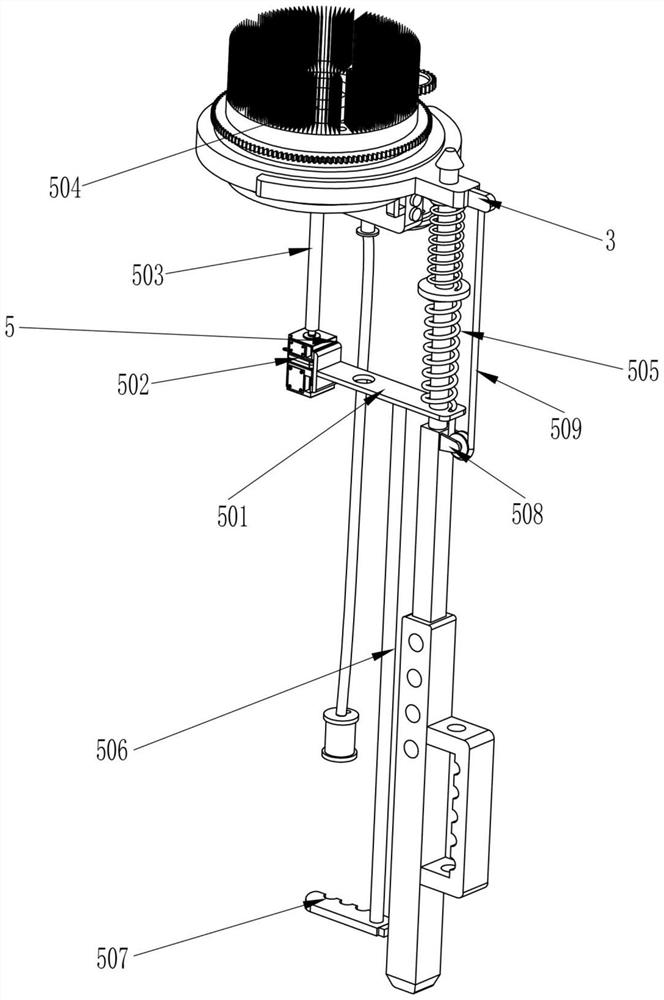

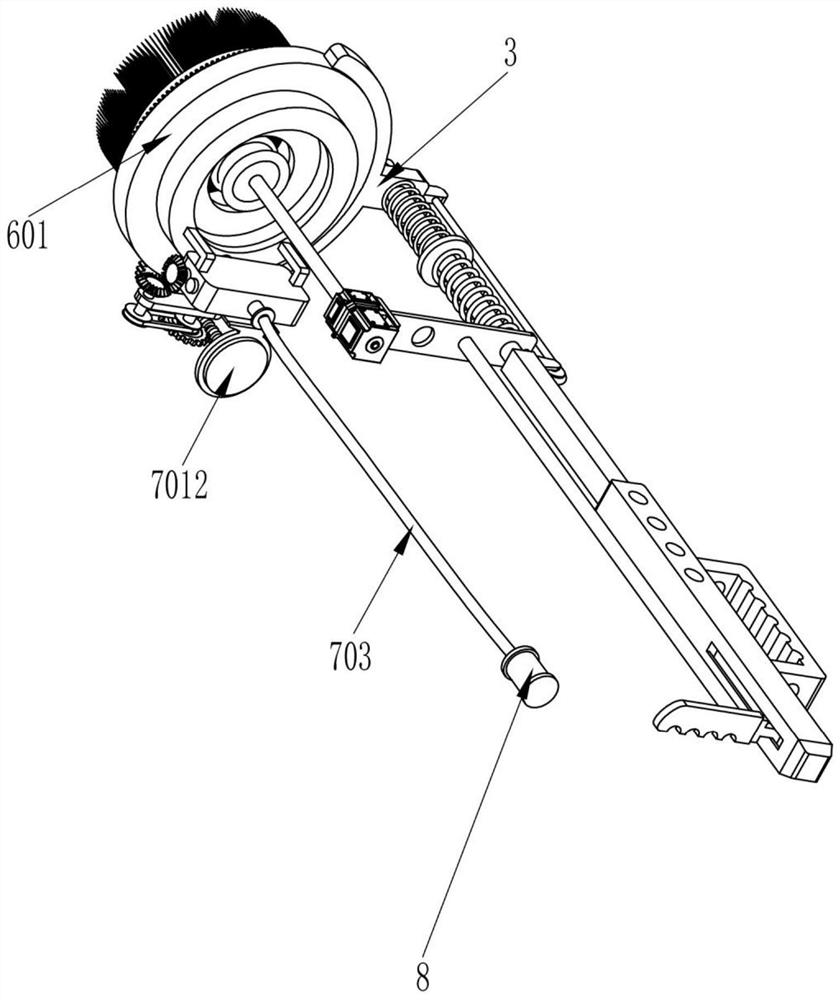

[0023] A bulb cleaning type installation device for a mine chandelier, such as Figure 1-7 As shown, it includes a handle 1, a sliding rod 2, a fixed sleeve 3, a first compression spring 4, a bulb loading and unloading device 5, a lamp holder dust brushing device 6 and a dust extraction device 7, and the sliding rod 2 is fixedly installed on the handle 1. The upper end of the fixing sleeve 3 is slidably installed on the sliding rod 2 and is far away from the handle 1. The upper end of the first compression spring 4 acting as a reset is fixedly connected with the lower side of the fixing sleeve 3, and the lower end is connected with the sliding The upper side of the round block on the rod 2 is fixedly connected, and the sliding rod 2 passes through the first compression spring 4, the bulb loading and unloading device 5 is installed on the sliding rod 2, and the lamp socket cleaning device 6 is installed on the fixed sleeve 3 And close to the bulb loading and unloading device 5 ...

Embodiment 2

[0027] A bulb cleaning type installation device for a mine chandelier, such as Figure 1-7 As shown, it includes a handle 1, a sliding rod 2, a fixed sleeve 3, a first compression spring 4, a bulb loading and unloading device 5, a lamp holder dust brushing device 6 and a dust extraction device 7, and the sliding rod 2 is fixedly installed on the handle 1. The upper end of the fixing sleeve 3 is slidably installed on the sliding rod 2 and is far away from the handle 1. The upper end of the first compression spring 4 acting as a reset is fixedly connected with the lower side of the fixing sleeve 3, and the lower end is connected with the sliding The upper side of the round block on the rod 2 is fixedly connected, and the sliding rod 2 passes through the first compression spring 4, the bulb loading and unloading device 5 is installed on the sliding rod 2, and the lamp socket cleaning device 6 is installed on the fixed sleeve 3 And close to the bulb loading and unloading device 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com