Nuclear power station shielding wall SC structure module hoisting method

A technology of structural modules and hoisting methods, applied in the directions of transportation and packaging, load hoisting components, etc., can solve the problems of difficult quality control, low overall rigidity, and many hoisting times, so as to achieve simple and easy hoisting methods and reduce hoisting times. , Guarantee the effect of hoisting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

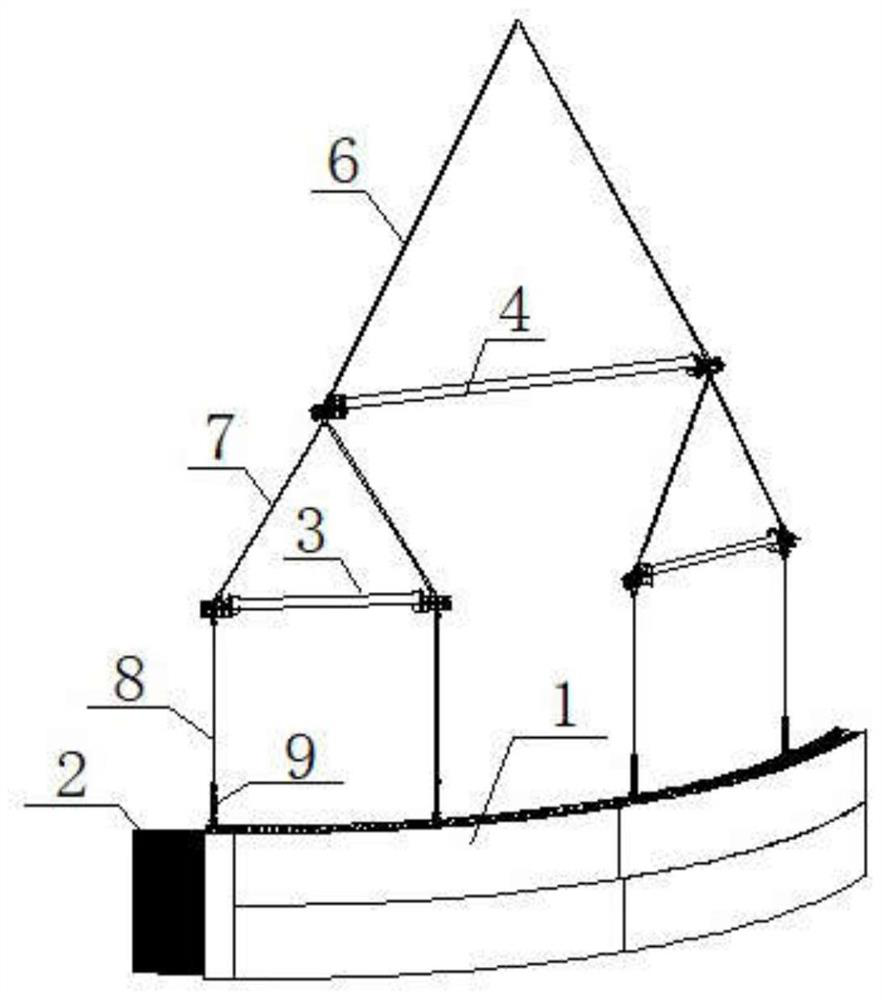

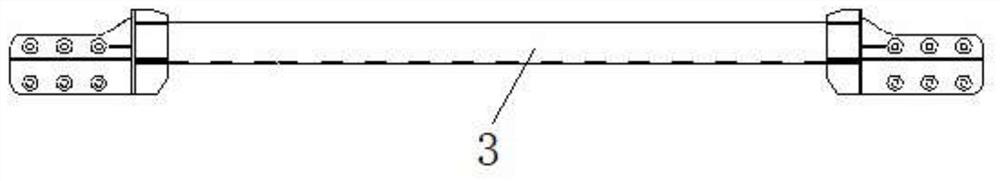

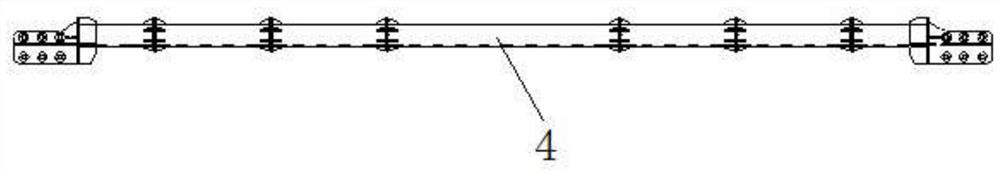

[0025] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0026] Such as figure 1 As shown, the present invention is a hoisting method for the SC structure module of the shielding wall of a nuclear power plant. The SC structure module is composed of 5 unit modules and anchoring steel bars. The arc length of the module is 32.2m, the height is 5.65m, and the weight is 82t. One side of the steel bar is heavy, and the five unit modules include four horizontal unit modules and one vertical unit module.

[0027] Step S1: Divide one part of the SC structure module into four parts, and calculate the lifting point positions of the four parts respectively;

[0028] Specifically: first calculate the center of gravity position of the SC structure module, the crane hook position is located at the vertical upper part of the center of gravity position, divide the SC structure module into two, obtain two sub-center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com