Vertical control system of crane hook and control method thereof

A control system and crane technology, applied in cranes, load hanging components, safety devices, etc., can solve the problems of high maintenance cost and poor monitoring effect, so as to improve safety, improve the scope of application of the system, and ensure detection accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

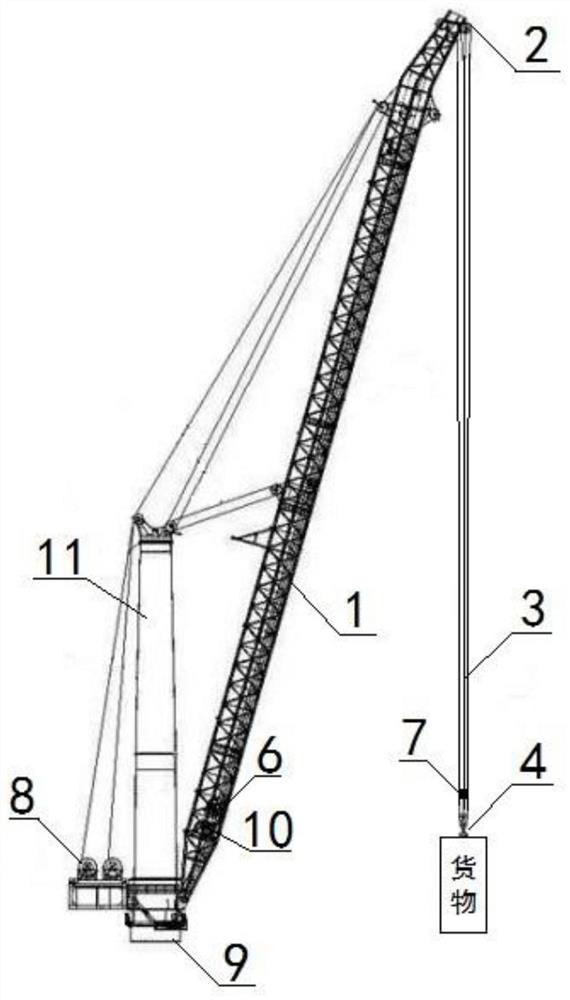

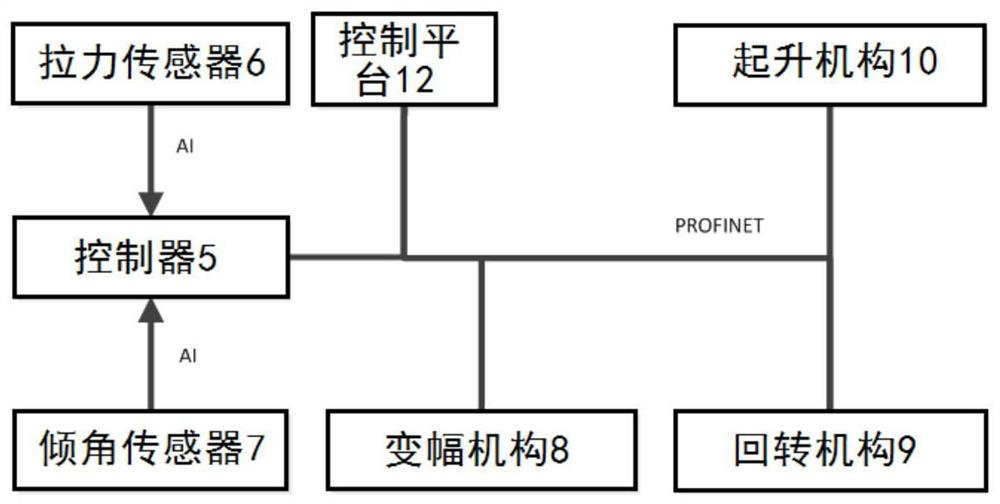

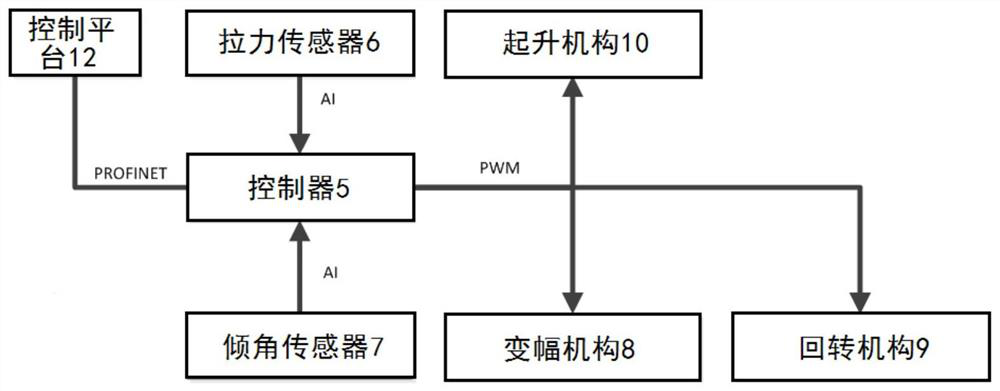

[0078] A crane hook vertical control system, the control system includes: boom 1, pulley 2, wire rope 3, hook 4, controller 5, tension sensor 6, inclination sensor 7, luffing mechanism 8, slewing mechanism 9, Lifting mechanism 10 and crane tower body 11; the top of the boom 1 is provided with a pulley 2 that rotates with it, the bottom of the boom 1 is connected with the crane tower body 11, and the bottom of the boom 1 is connected with the crane The tower body 11 rotates and cooperates, the rotation axis of the boom 1 is set horizontally, the luffing mechanism 8 is in transmission cooperation with the boom 1, the slewing mechanism 9 is in transmission cooperation with the bottom of the crane tower body 11, and the crane tower body The bottom of 11 rotates with the top of the crane chassis, and the crane tower 11 is provided with a hoisting mechanism 10, and the hoisting mechanism 10 is provided with a tension sensor 6, and the tension sensor 6 is used for measuring Pulling f...

Embodiment 2

[0093] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0094] The control method also includes a calibration step of the tension sensor 6, the calibration step of the tension sensor 6 is performed by the operator during the crane installation stage or the crane maintenance stage, and the calibration step of the tension sensor 6 is as follows:

[0095] The operator operates the control platform 12 to manually input the empty hook weight of the hook 4, which is the tension detected by the tension sensor 6 when the hook 4 is at the same height as the top of the cargo to be lifted; 4. After the empty weight is checked, the operator operates the controller 5 to enter the calibration step and perform the second preparation step, the third step detection step and the fourth step adjustment step. At the same time, the operator observes the working condition of the crane. When the goods are hoisted off the ground or the hoisting mechanism 10 does not start ...

Embodiment 3

[0097] Embodiment 3 is basically the same as Embodiment 2, and its difference is:

[0098] The control method also includes a calibration step of the inclination sensor 7, the calibration step of the inclination sensor 7 is performed by the operator during the crane installation stage or the crane maintenance stage, and the calibration steps of the inclination sensor 7 are as follows:

[0099] The operator operates the controller 5 to enter the calibration step and keeps the hook 4 vertically downward. The operator operates the controller 5 to calibrate the inclination signal sent by the inclination sensor 7 at this time to be 0 degrees, and the operator operates the controller after calibrating the 0 degree inclination signal 5. Input the safety threshold of the crane. After the operator enters the safety threshold of the crane, operate the crane to perform the second preparation step, the third detection step and the fourth adjustment step to calibrate the safety threshold of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com