Novel hot-pressing medicine bottle cover pharmacy production line

A production line and bottle cap technology, which is applied to bottle/container caps, bottle filling, and capping containers tightly, etc. It can solve the problems of affecting the quality of liquid medicine, increasing labor costs, and laborious labor, and achieves low cost and easy use. Reliable, cost-reducing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

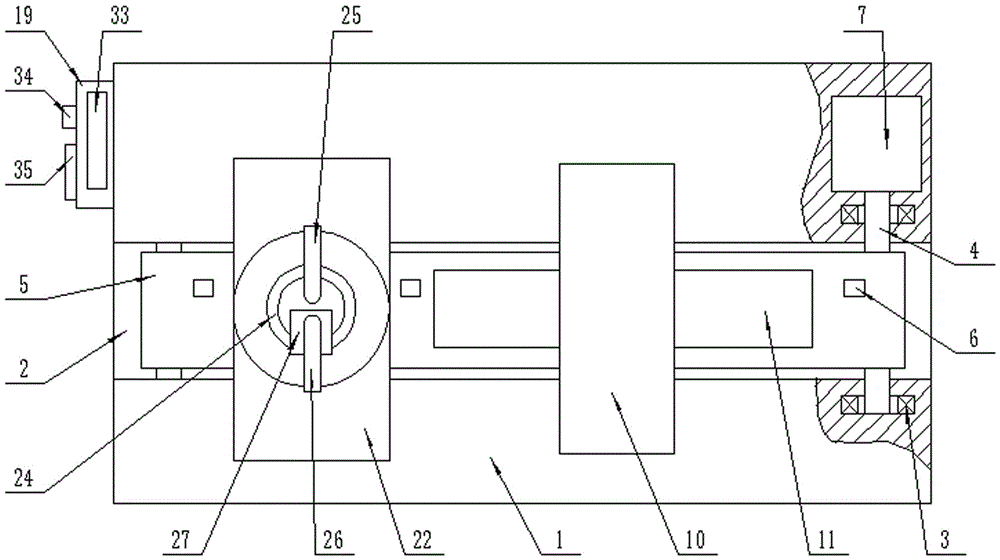

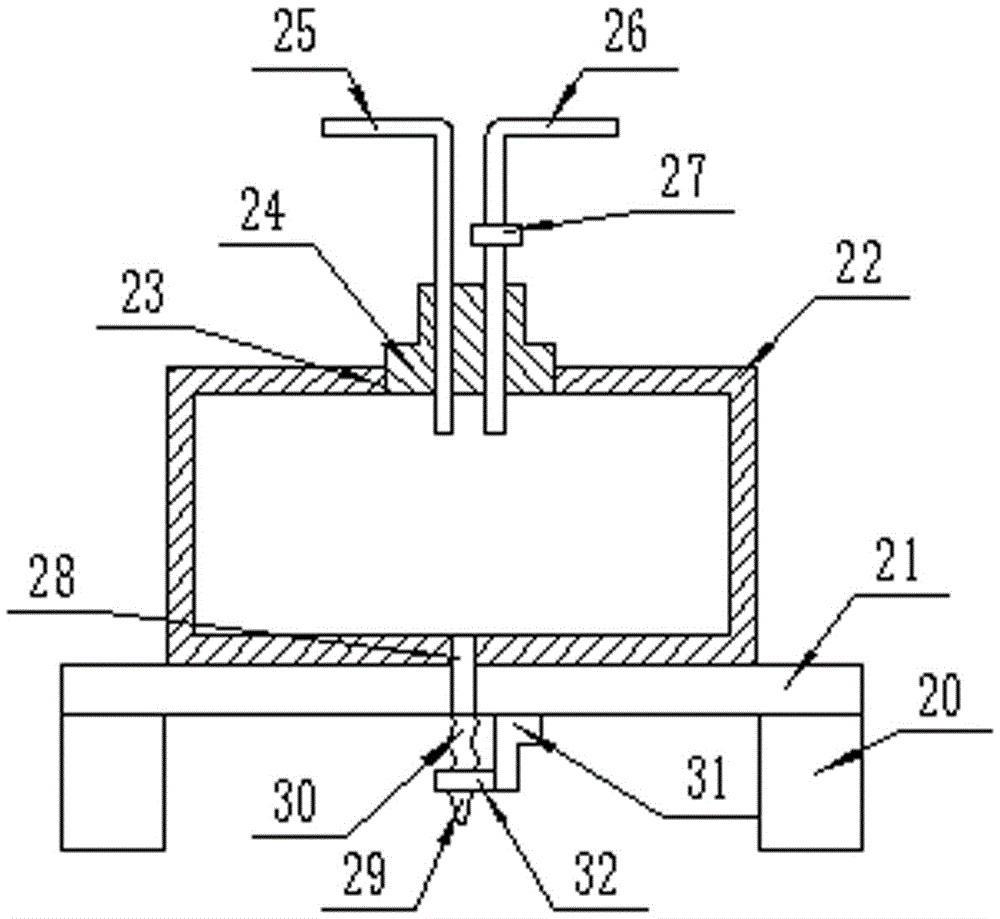

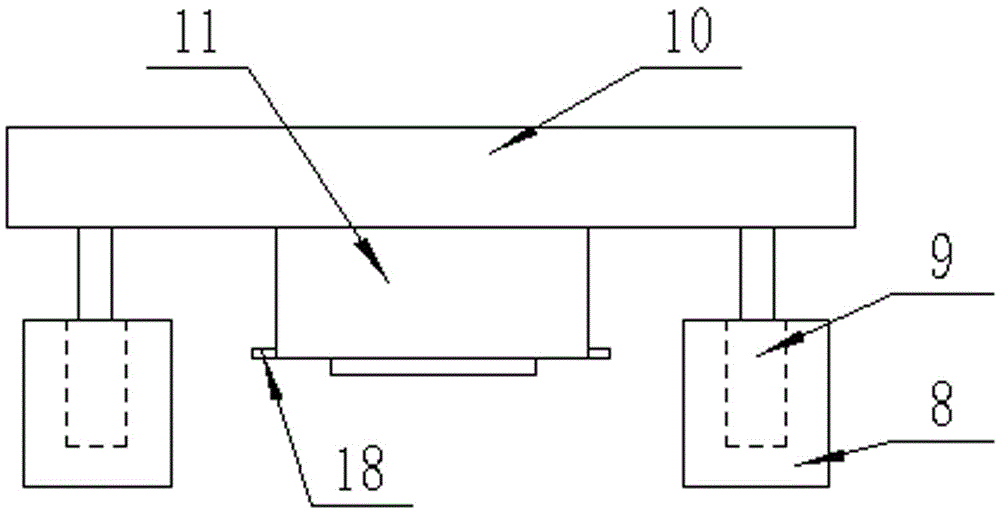

[0020] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 As shown, a new type of hot-pressed medicine bottle cap pharmaceutical production line, including a base (1), the upper surface of the base (1) is provided with a through groove (2) along its length direction, and the through groove (2) There is a transmission mechanism inside. The transmission mechanism consists of two sets of bearings (3) located on both sides of the through groove (2), a rotating shaft (4) inserted in the corresponding set of bearings (3), and a set of two sets of bearings (3). The conveyor belt (5) on the first rotating shaft (4), the flexible LED illuminant (6) embedded on the surface of the conveyor belt (5), and the rotating shaft (4) located in the base (1) and the rotating end connected to one of them The motor (7) jointly constitutes, the upper surface of the base (1) is sequentially provided with a liquid medicine filling mechanism a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com