Guardrail protection component capable of changing height along with seawater rising tide

A guardrail and height technology, applied in coastline protection, fences, breakwaters, etc., can solve the problems of reducing the service life of shore railings, lack of wave diversion buffer structure, and shortening service life of guardrails, so as to reduce impact and improve service life. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

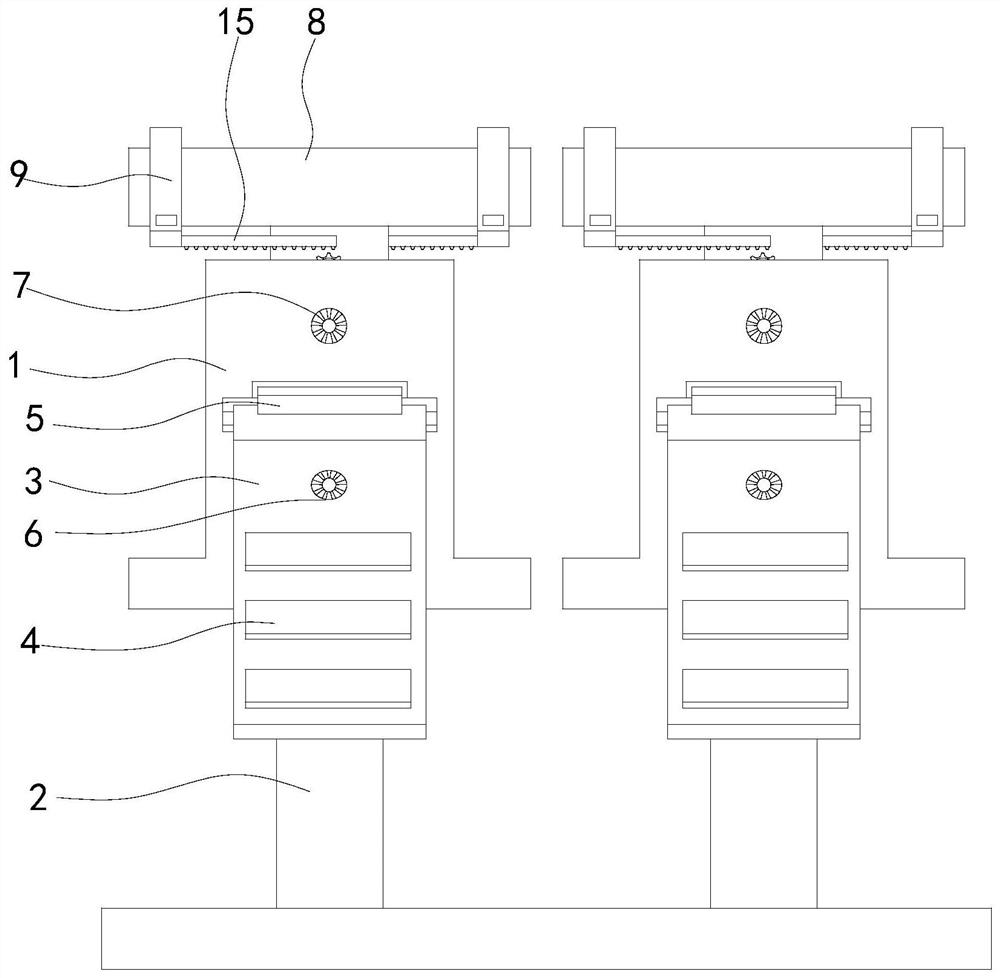

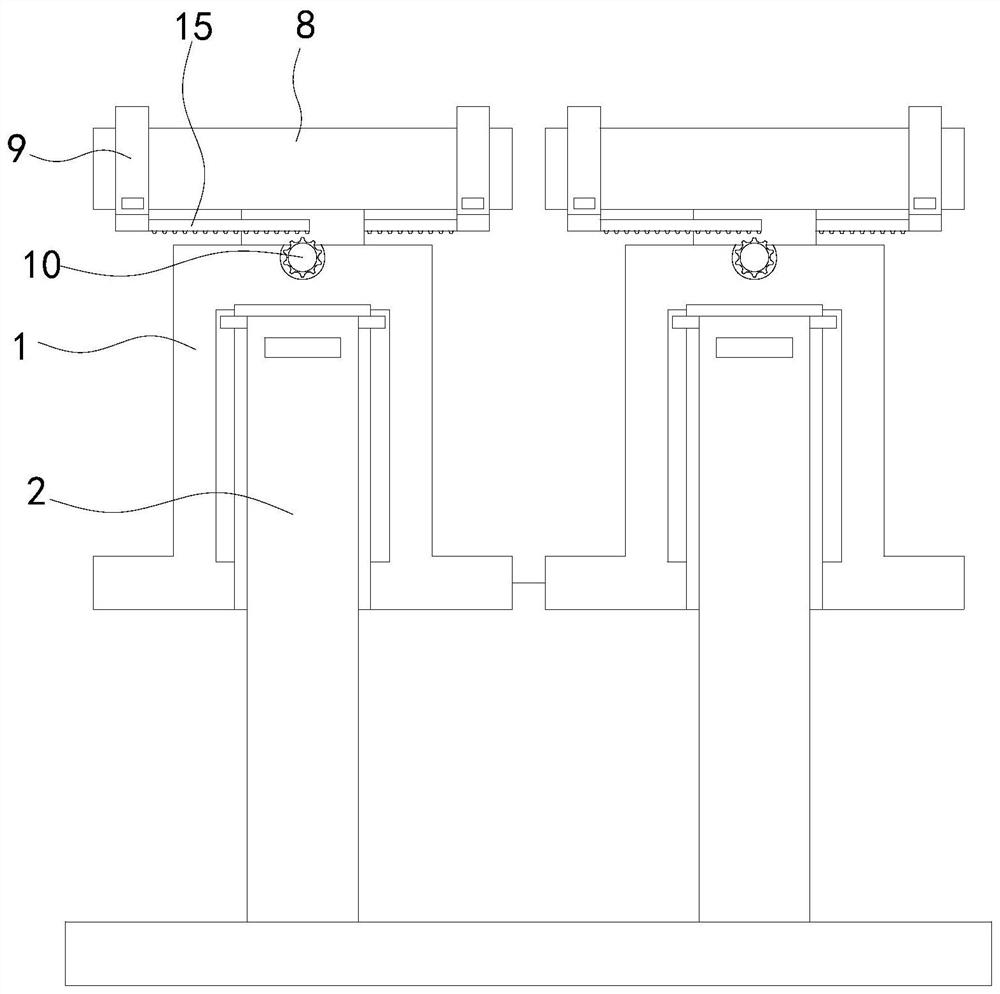

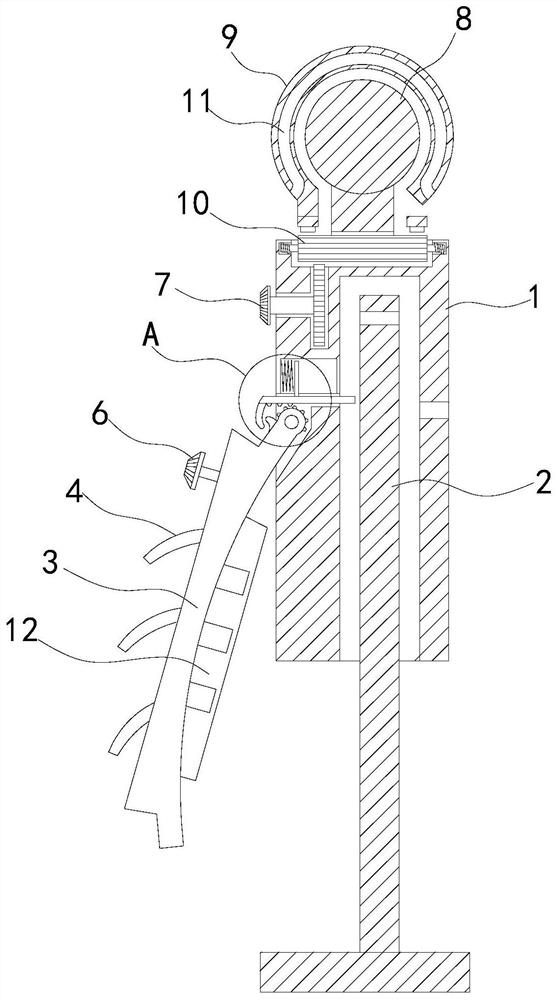

[0025] see Figures 1 to 7 , a schematic plan view and a three-dimensional structure view of a guardrail protection component that can change with seawater tide height.

[0026] A guardrail protection assembly that can change with the height of the sea tide, comprising a guardrail main body 1 and a guardrail column 2, the front of the guardrail main body 1 is movably installed with a wave baffle 3, the inside of the wave baffle 3 is fixedly installed with a deflector 12, and the upper end of the guardrail main body 1 is fixed A crossbeam 8 is installed, and a cleaning ring 9 is movably sleeved on the outside of the crossbeam 8 .

[0027] In the specific implementation, the guardrail main body 1 is movably socketed on the outside of the guardrail column 2, and the outside of the wave breaker 3 is fixedly installed with an inclined arc-shaped force plate 4, so that when the sea waves hit the wave breaker 3 after the sea tide rises, the wave breaker 3 can be used. The force plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com