Rotary flushing equipment for casing production and processing

A technology for equipment and casings, which is applied in the field of rotary washing equipment, can solve the problems of inability to recycle water resources, limited effect, pollution, etc., and achieve the effect of improving the recycling rate, improving the stability of operation, and improving the cleaning range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

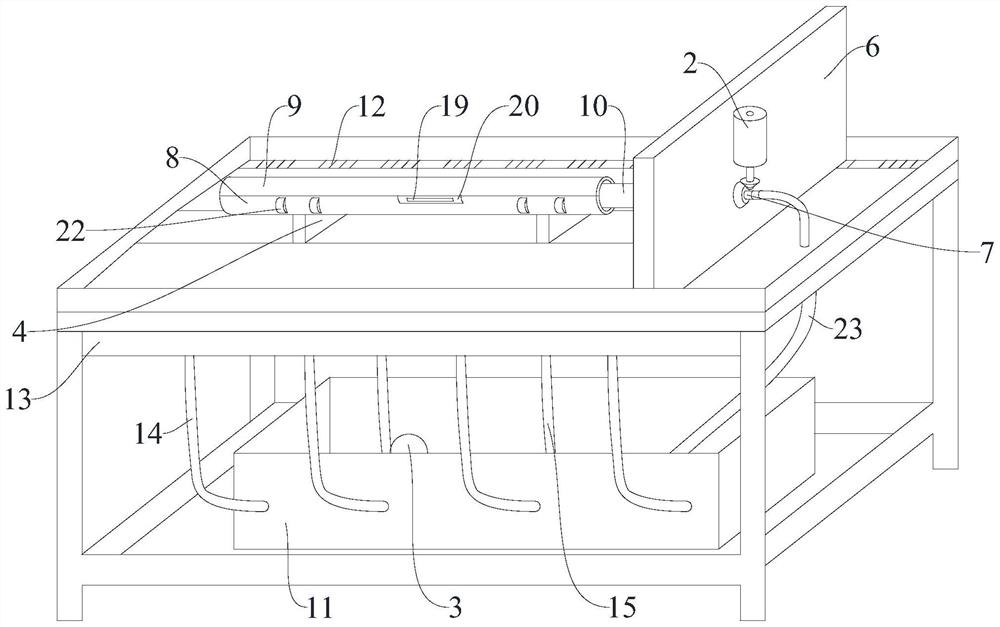

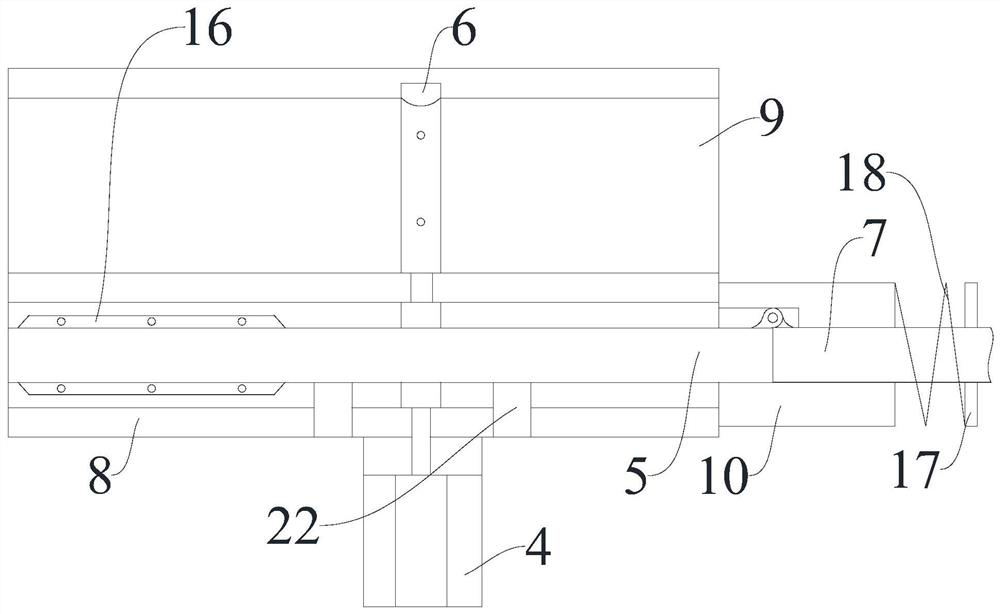

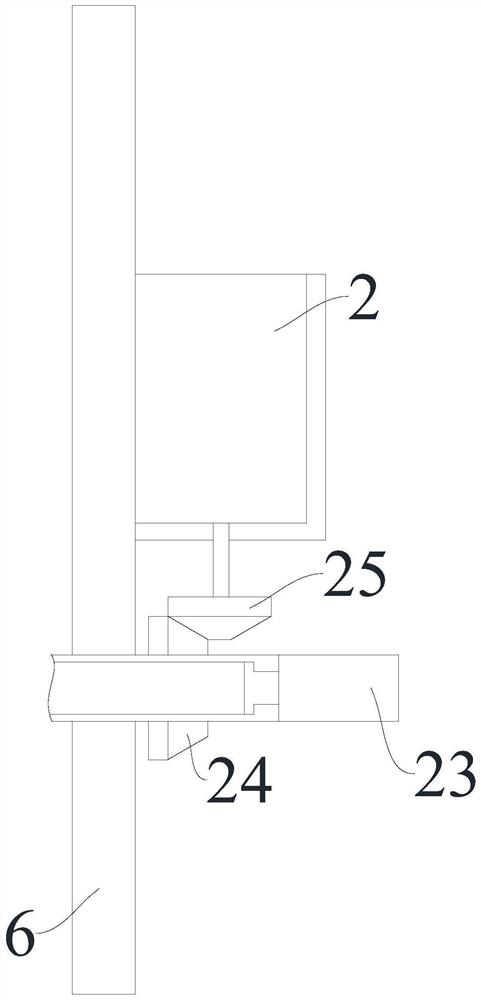

[0022] Example: People put the opening of the right end of the pig's small intestine on the horizontal transmission tube 5, then fix the two ends of the pig's small intestine, and then turn on the driving motor 2, and the driving motor drives the horizontal transmission tube 5 and the horizontal transmission tube 7 to rotate, and the horizontal transmission tube 7 The lateral convex strip 16 on the outside scrapes the inner wall of the small intestine of the pig, and at the same time starts the small booster pump 3 to guide the water from the external drain pipe 23 into the horizontal transmission tube 5 and the horizontal transmission tube 7, and then from the lateral convex strip 16 sprays out from the side water spray holes, and at the same time, water is introduced into the inner drain pipe 21 of the arc-shaped bottom mounting plate 8 and the arc-shaped top mounting plate 9 through the internal drain pipe 15, and then water is sprayed from the inner side of the internal drai...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap