Concrete stirring tank outlet inner wall cleaning device and use method thereof

A technology for cleaning devices and mixing tanks, which is applied to cleaning methods and appliances, chemical instruments and methods, and cleaning hollow objects, etc. It can solve problems such as unsatisfactory cleaning effects and inability to remove stubborn solid attachments, so as to achieve improved cleaning Effectiveness and reliability, the effect of improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

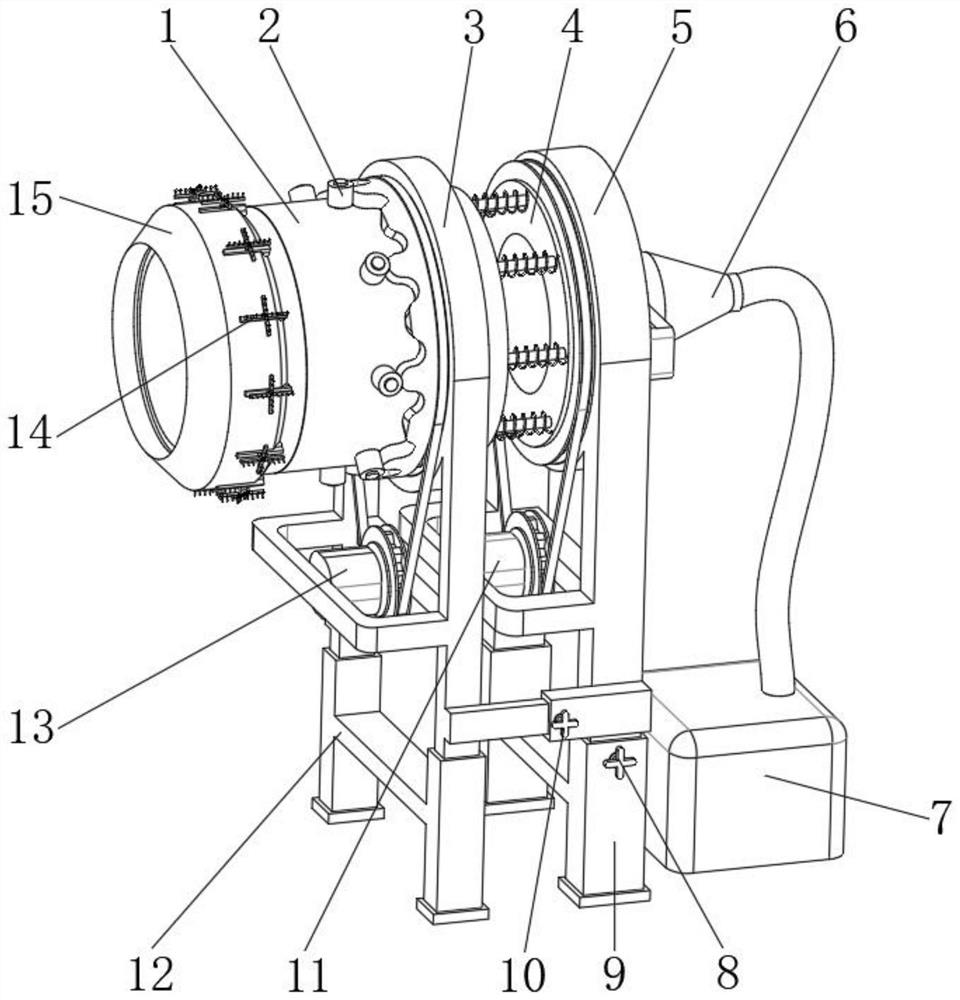

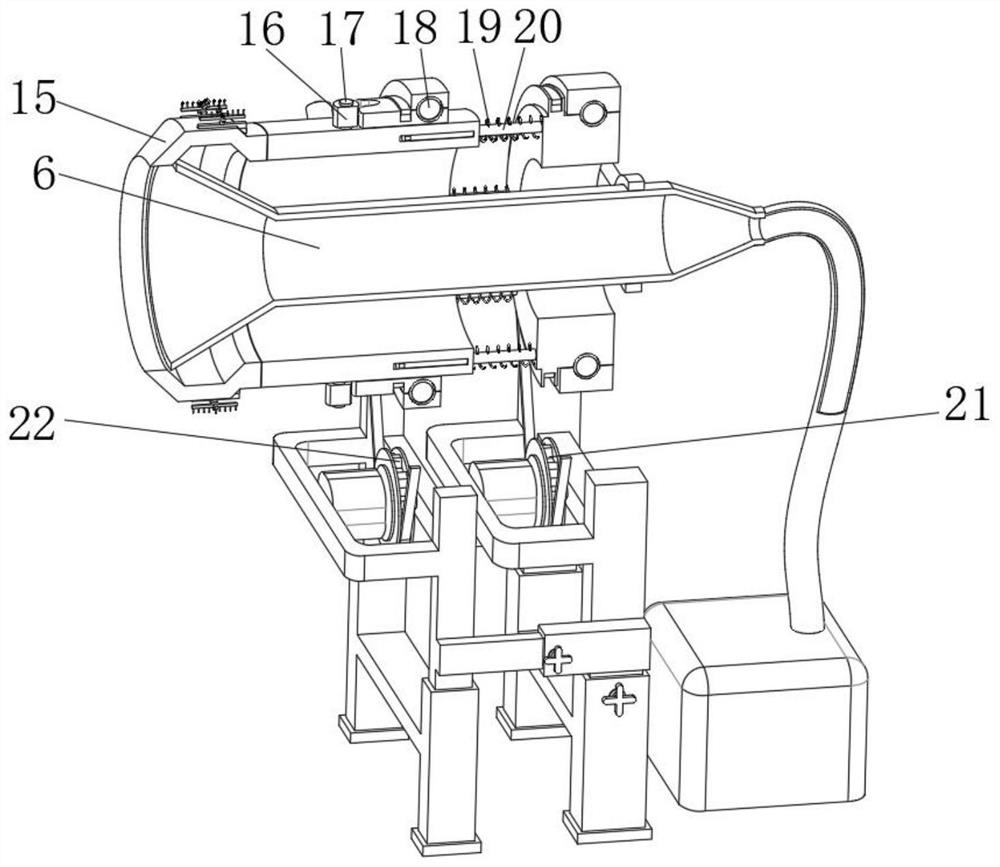

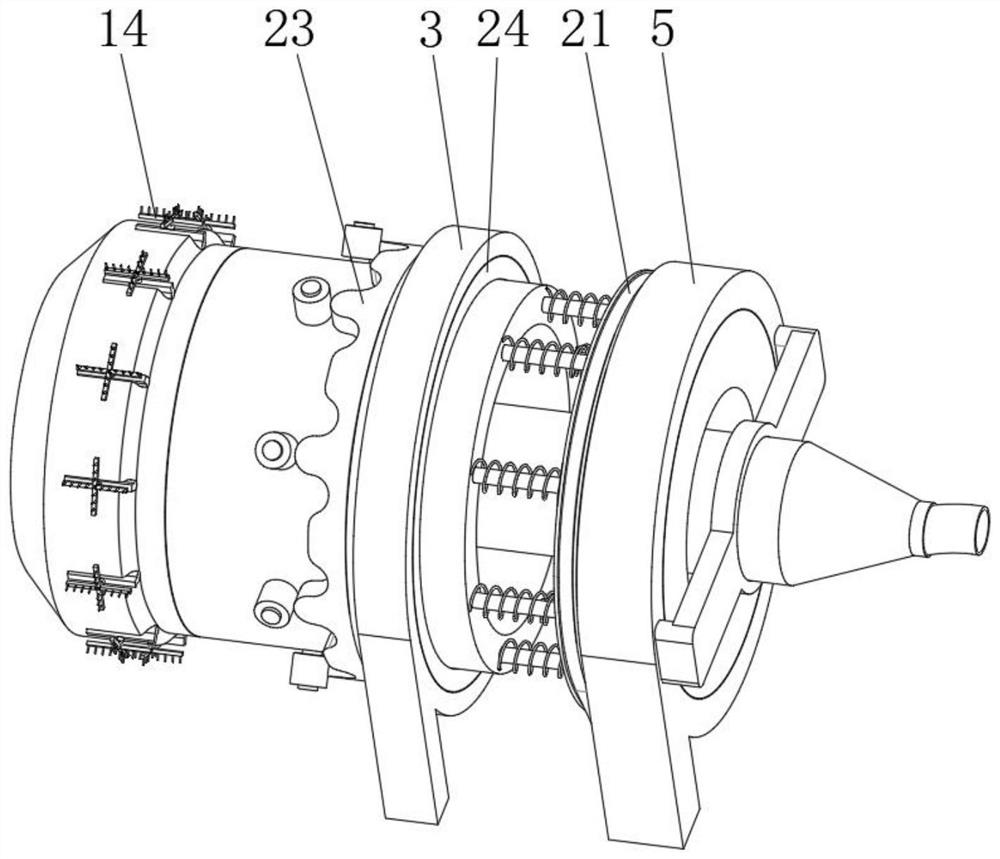

[0045] A device for cleaning the inner wall of the outlet of a concrete mixing tank, such as Figure 1-5 As shown, it includes a connection seat 1 and a first support frame 5, the inner wall of the first support frame 5 is slidably connected with a first rotating seat 4, and the outer wall of one side of the first rotating seat 4 is fixed with evenly distributed connecting rods 20 by screws. One end of the connecting rod 20 is slidably connected to the inner wall of one side of the connecting seat 1 through a limit block, and the outside of the connecting rod 20 is covered with a stretched spring 19, and the two ends of the spring 19 are respectively welded to the outer wall of one side of the connecting seat 1 and the first rotating The outer wall on one side of the seat 4, the outer wall on the other side of the connecting seat 1 is fixed with a cleaning seat 15 by screws, the outer wall of the cleaning seat 15 is provided with evenly distributed cleaning parts 14, and the ou...

Embodiment 2

[0055] A method for using a device for cleaning the inner wall of a concrete mixing tank outlet, comprising the following steps:

[0056] S1: Adjust the height of the cleaning seat 15, first lift the first support frame 5 and the second support frame 3 from the first base 9 and the second base 12 to a suitable height, so that the cleaning seat 15 is compatible with the outlet of the mixing tank, and then pass The lifting adjustment knob 8 is locked and fixed;

[0057] S2: Adjust the range of horizontal and lateral movement of the cleaning part 14, move the second support frame 3 horizontally in the first support frame 5, and lock and fix it by the translation adjustment knob 10;

[0058] S3: Adjust the cleaning force, adjust the extension of the cleaning plate 28 relative to the assembly seat 31 through the limit screw 29, thereby changing the radius of rotation, or changing the deformation of the cleaning head 30 in contact with the inner wall of the outlet of the mixing tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com