Novel sand slinger for producing fasteners

A technology of fasteners and sand blasting machines, applied in the field of sand blasting machines, which can solve the problems of inconvenient material discharge, inconvenient buffer function, inconvenient adjustment of the height of the chassis, etc., and achieve the effect of increasing the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

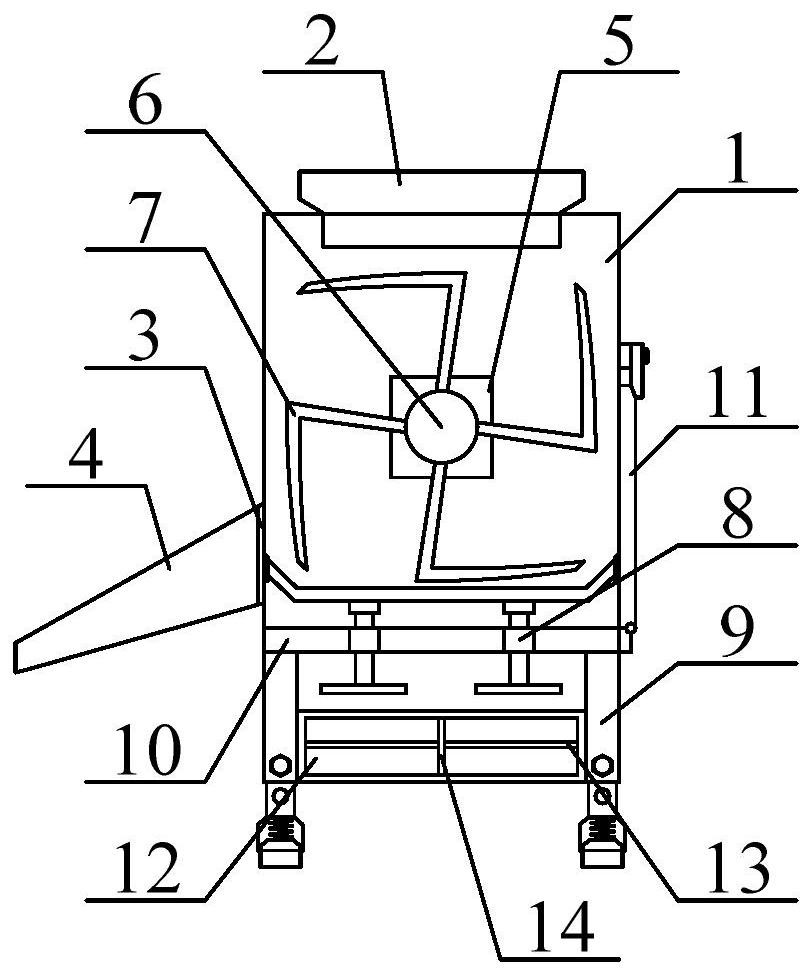

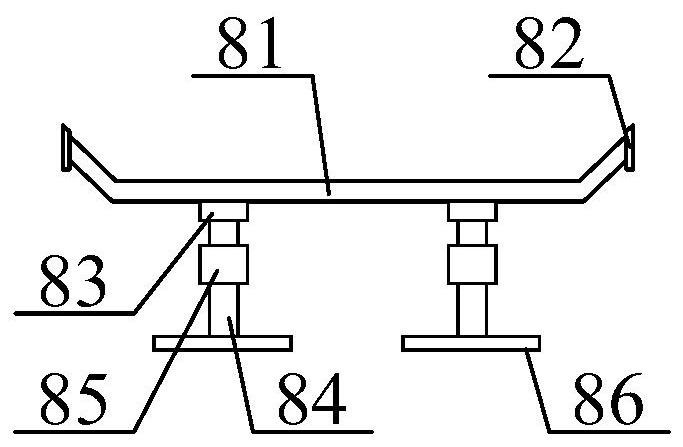

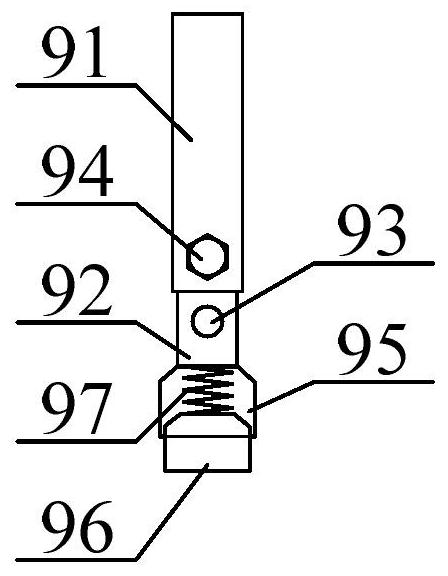

[0028] as attached figure 1 And attached figure 2 As shown, a new type of sandblasting machine for producing fasteners according to the present invention includes a rectangular outer frame 1, a hopper 2, a longitudinal plate 3, an outlet hopper 4, a driving motor 5, a rotating roller 6, and an L-shaped shovel Material plate 7, adjustable underframe structure 8, adjustable buffer support structure 9, horizontal mounting plate 10, just disassembled material rack structure 11, tool box 12, horizontal plate 13 and longitudinal partition 14, described feeding hopper 2 The bolts are installed on the upper side of the rectangular outer frame 1; the bolts of the longitudinal plate 3 are installed on the lower left side of the rectangular outer frame 1; the bolts of the export bucket 4 are installed on the left side of the longitudinal plate 3; The driving motor 5 bolts are insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com