Label defective product removal mechanism and label inspection machine provided with mechanism

A label and poor technology, applied in the direction of winding strips, sending objects, thin material processing, etc., can solve the problems of reducing the efficiency of inspection, stopping operation, consuming the energy of staff, etc., to reduce the use of manpower and improve the detection efficiency. Efficiency, not easy to fall off at will

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

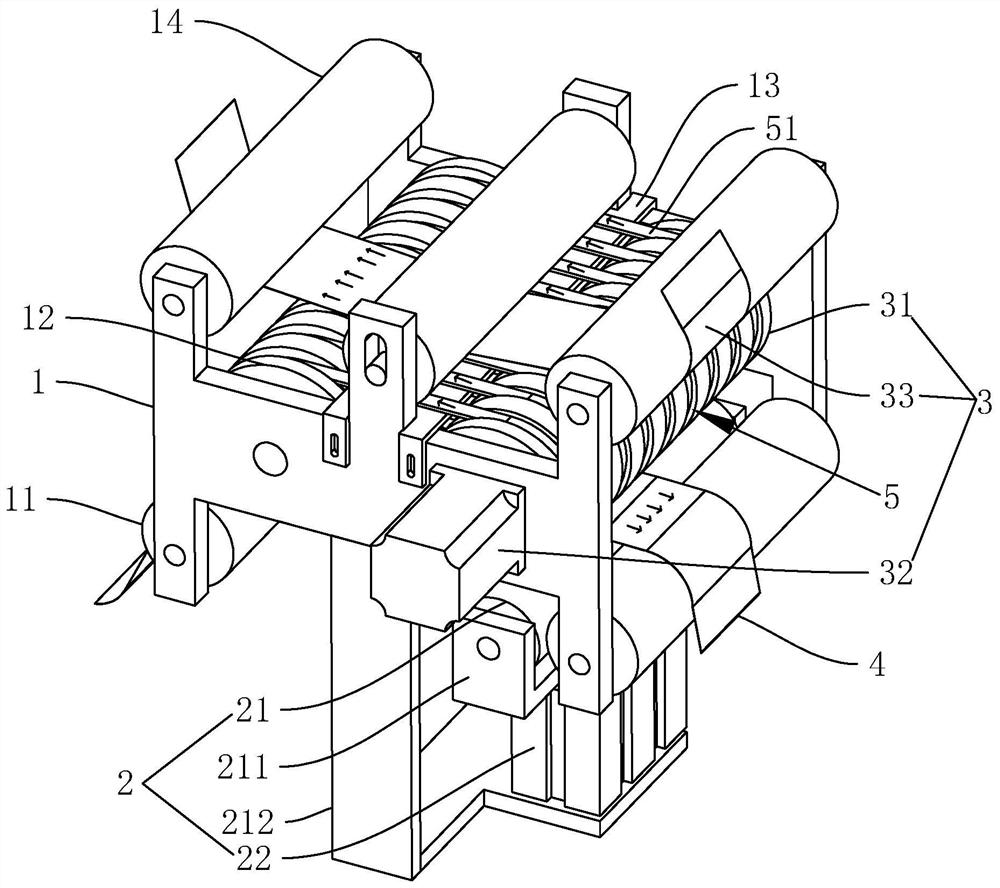

[0035] Embodiment one, with reference to figure 1, is a label defective product removal mechanism disclosed by the invention, which can automatically remove the defective product label on the material belt 4, saves manpower, and improves detection efficiency. The mechanism includes a frame 1, and the frame 1 includes two vertical Parallel plate body, the plate body is made of stainless steel; the frame 1 is respectively provided with a jacking assembly 2 and a receiving assembly 3, the jacking assembly 2 is opposite to the receiving assembly 3 up and down, and the jacking assembly 2 is on the lower side of the frame 1 , the receiving assembly 3 is on the upper side of the frame 1, and the material tape 4 with the detected label (release paper with the label attached) passes between the jacking assembly 2 and the receiving assembly 3; the jacking assembly 2 It is used to push the material belt 4 away from the surface of the label side and push the material belt 4 to the side of...

Embodiment 2

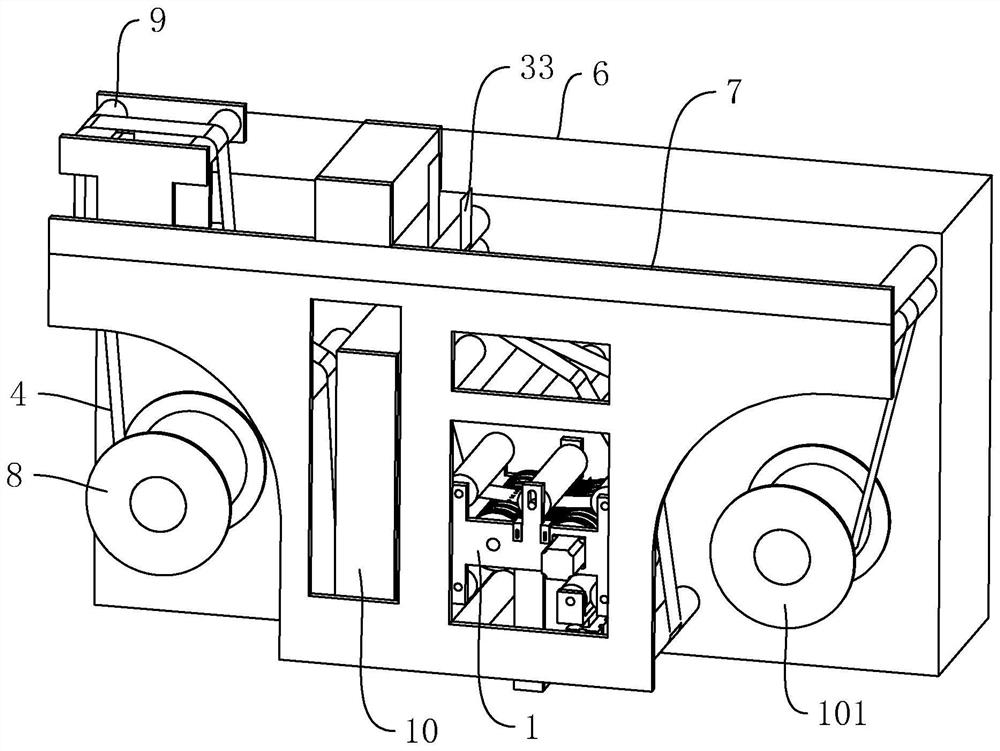

[0045] Embodiment two, refer to figure 2 , based on a label defect removal mechanism in Embodiment 1, the present invention also proposes a label product inspection machine, which includes: a chassis 6, a frame body 7, an unwinding part 8, several guide rollers 9, and a detection part 10 And the winding part 101, the unwinding part 8, the frame body 7, several guide rollers 9, the detection part 10 and the winding part 101 are all at the side surface of the cabinet 6, wherein the unwinding part 8, several guide rollers 9 and One end of the winding part 101 is connected to the cabinet 6 in rotation and is inside the frame body 7; the inside of the cabinet 6 is provided with a motor that drives the unwinding part 8, several guide rollers 9 and the winding part 101 to move in the same direction, and the frame body 7 is fixed on the chassis 6 by screws; the detection part 10 is fixed inside the frame body 7 by screws; the defective label removal mechanism is arranged inside the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com