On-site assembly type roof maintenance climbing ladder

A technology for on-site assembly and climbing ladders, applied in ladders, buildings, building structures, etc., can solve problems such as twisting deformation, twisting deformation, and falling off of cage hoop of climbing ladders, so as to ensure stability, reduce weight, and strengthen strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

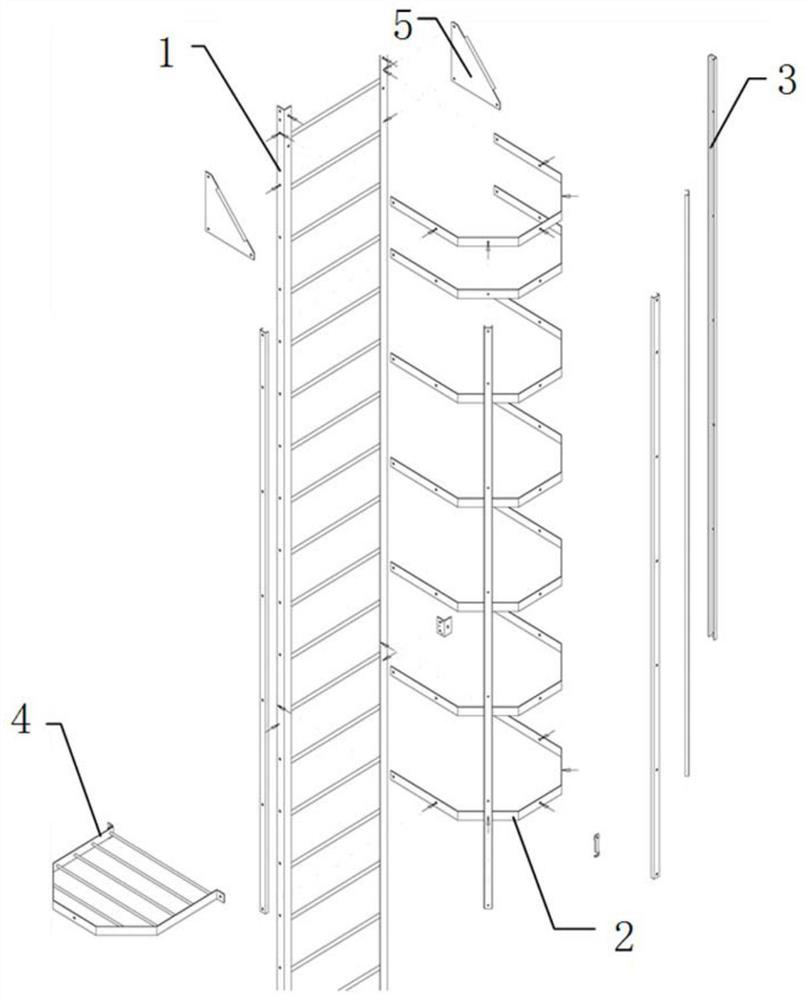

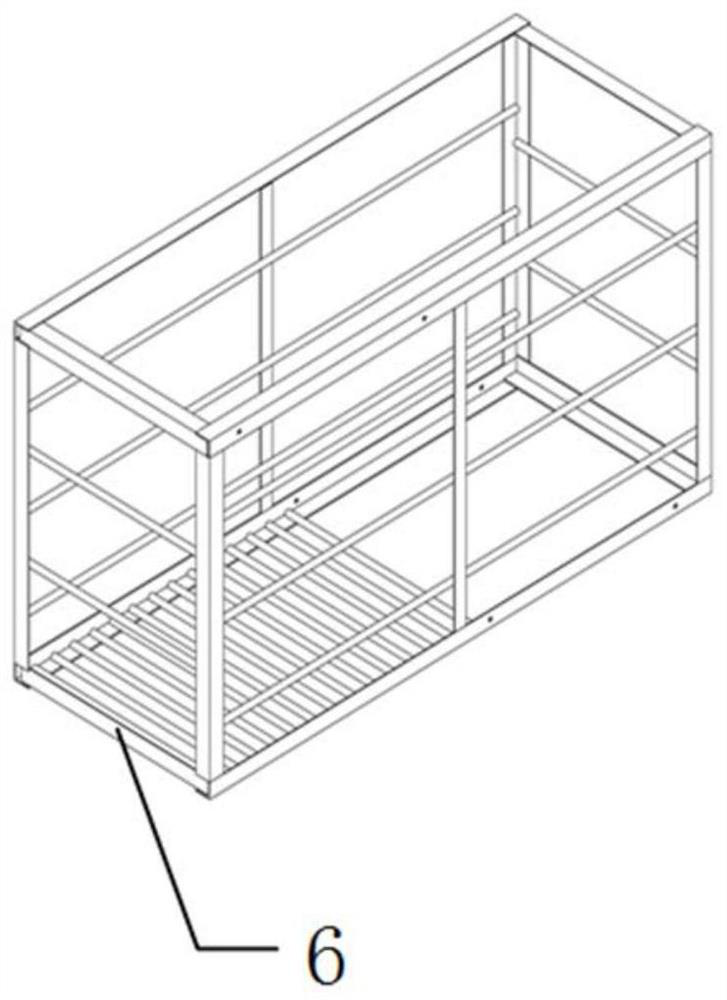

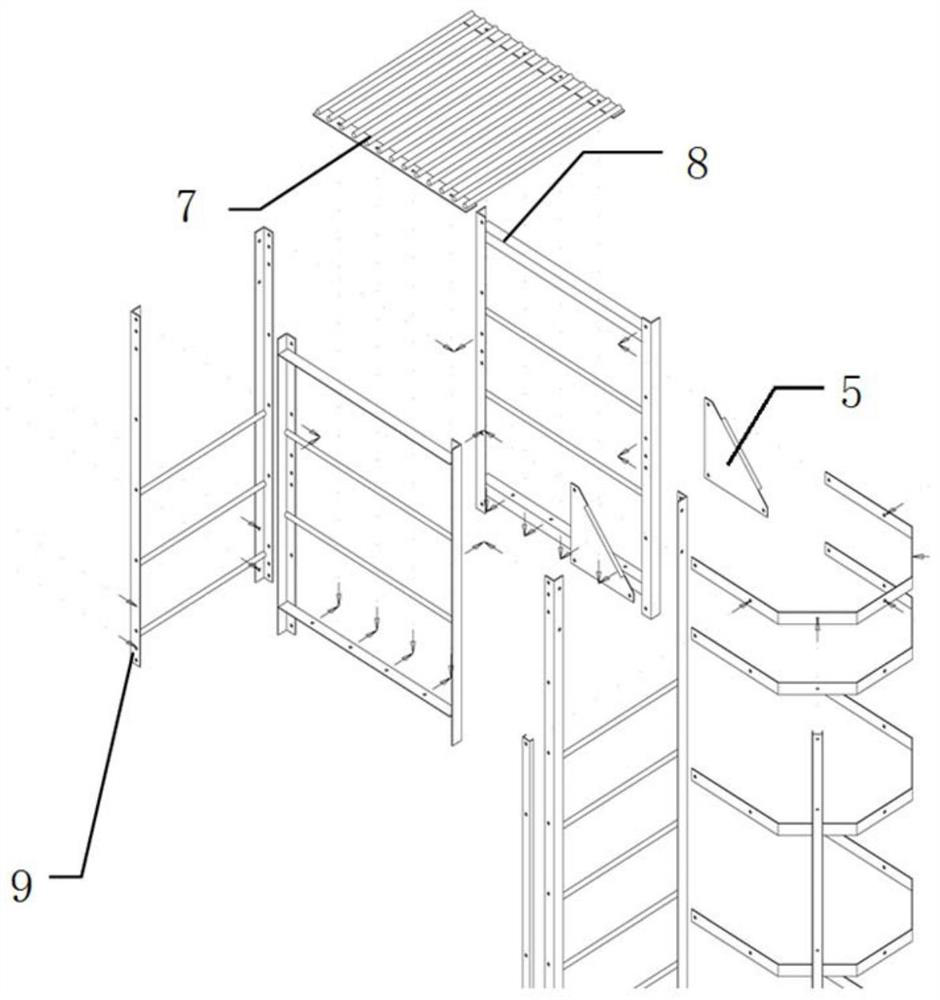

[0041] like Figure 1~3 As shown, the present application proposes a field-assembled roof maintenance ladder, and the entire ladder is designed in a standardized manner, including the ladder section 1 and the cage assembly arranged on the ladder section 1 . For ladders with a climbing height greater than 10 meters, according to the requirements of the national standard "GB4053.1 2009", a rest platform 6 needs to be set in the middle of the ladder section, which divides the entire ladder section into two upper ladder sections 12 and lower ladder sections 13 arranged staggered left and right. part. In this embodiment, a top platform is provided on the top of the stair section 1 . This climbing ladder is except the rest platform 6, is planar member, is convenient to make, transport, and rest platform 6 can be used as the framework of the overall packaging of small parts such as cage hoop 2, cage wicket 4 and structural connector simultaneously.

[0042] The cage assembly includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com