Noise-reduction and shock-absorption device for electromechanical equipment in metallurgical production industry

A technology of electromechanical equipment and shock absorbers, which is applied in the direction of mechanical equipment, engine frames, springs/shock absorbers, etc., can solve the problems of multiple noises, poor shock and noise reduction effects, and high cost, so as to improve performance and facilitate movement , improve the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

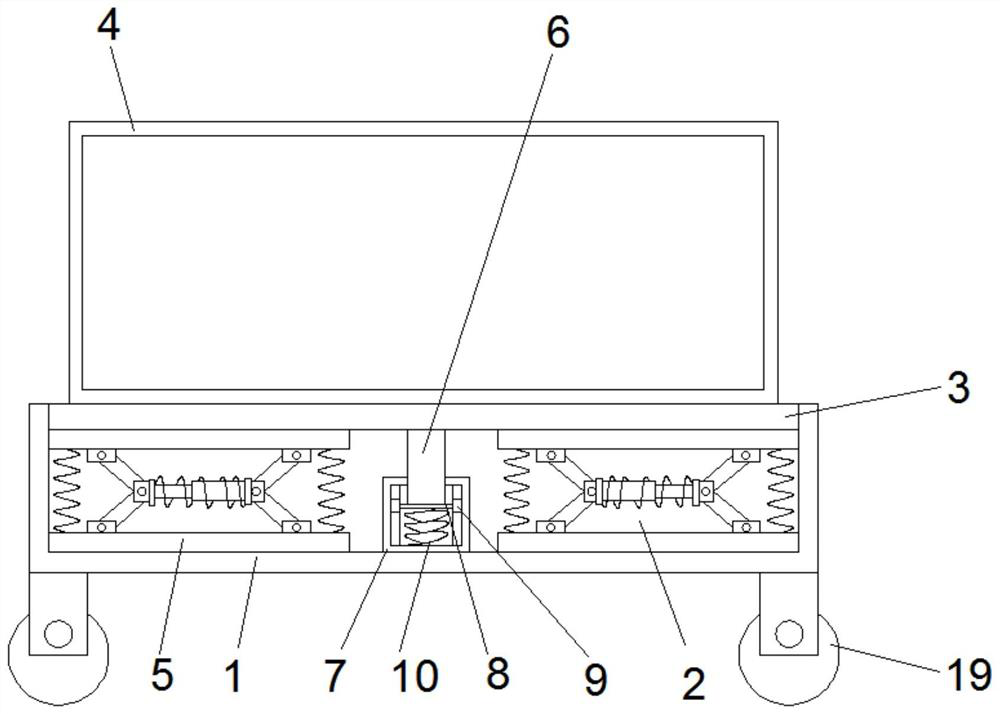

[0021] see Figure 1-2 According to an embodiment of the present invention, a noise reduction and shock absorbing device for electromechanical equipment in the metallurgical production industry includes a shock absorber 1, and a shock absorber 2 is provided on the shock absorber 1, and the shock absorber 2 The top is provided with a support base 3, the top of the support base 3 is equipped with electromechanical equipment 4, the bottom of the support base 3 is symmetrically provided with a shock absorbing mechanism 5, and the middle end of the bottom of the support base 3 is fixedly provided with a connecting column 6. One end of the connecting column 6 passes through the sleeve 7 and extends into the sleeve 7 to be fixedly connected with the limit plate 8. The sleeve 7 is fixed in the shock absorbing groove 2, and the inside of the sleeve 7 is symmetrical. A limit groove is provided, and a matching limit block 9 is provided inside the limit groove, and the two ends of the lim...

Embodiment 2

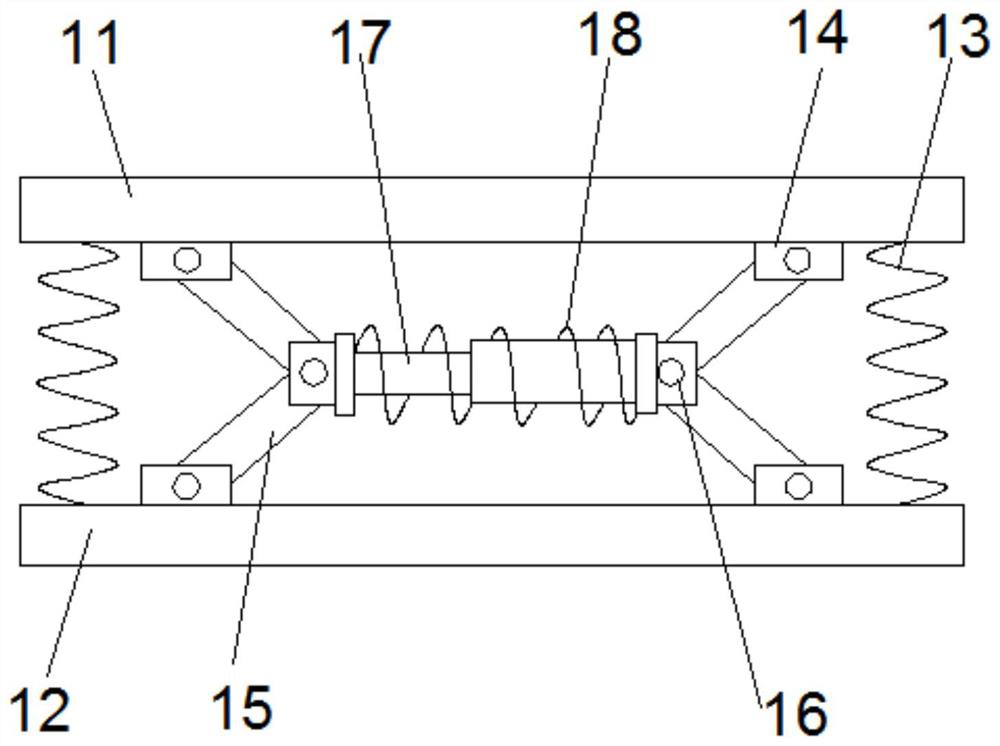

[0023] see Figure 1-2 , for the shock absorbing mechanism 5, the shock absorbing mechanism 5 includes an upper pressing plate 11 and a lower pressing plate 12, the top of the upper pressing plate 11 is fixedly connected with the support seat 3, and the lower pressing plate 12 is connected with the shock absorbing recess The inner wall of the groove 2 is fixedly connected. For the upper pressing plate 11, a buffer spring 13 is fixedly connected between the upper pressing plate 11 and the lower pressing plate 12, and the bottom of the upper pressing plate 11 and the top of the lower pressing plate 12 are symmetrically fixed and provided with a rotating spring. Block one 14, the first rotating block 14 is movably connected with a movable rod 15, and the other end of the movable rod 15 is movably connected with the rotating block two 16. For the second rotating block 16, a telescopic rod 17 is fixed between the second rotating block 16, and a buffer spring three 18 is fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com