Hybrid shock absorber for full automatic washing machine

A fully automatic washing machine, hybrid technology, applied to other washing machines, applications, washing devices, etc., can solve problems such as easy to generate abnormal noise, avoid impact vibration and noise, improve product vibration and noise quality, improve transient start and The effect of the steady-state dynamics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

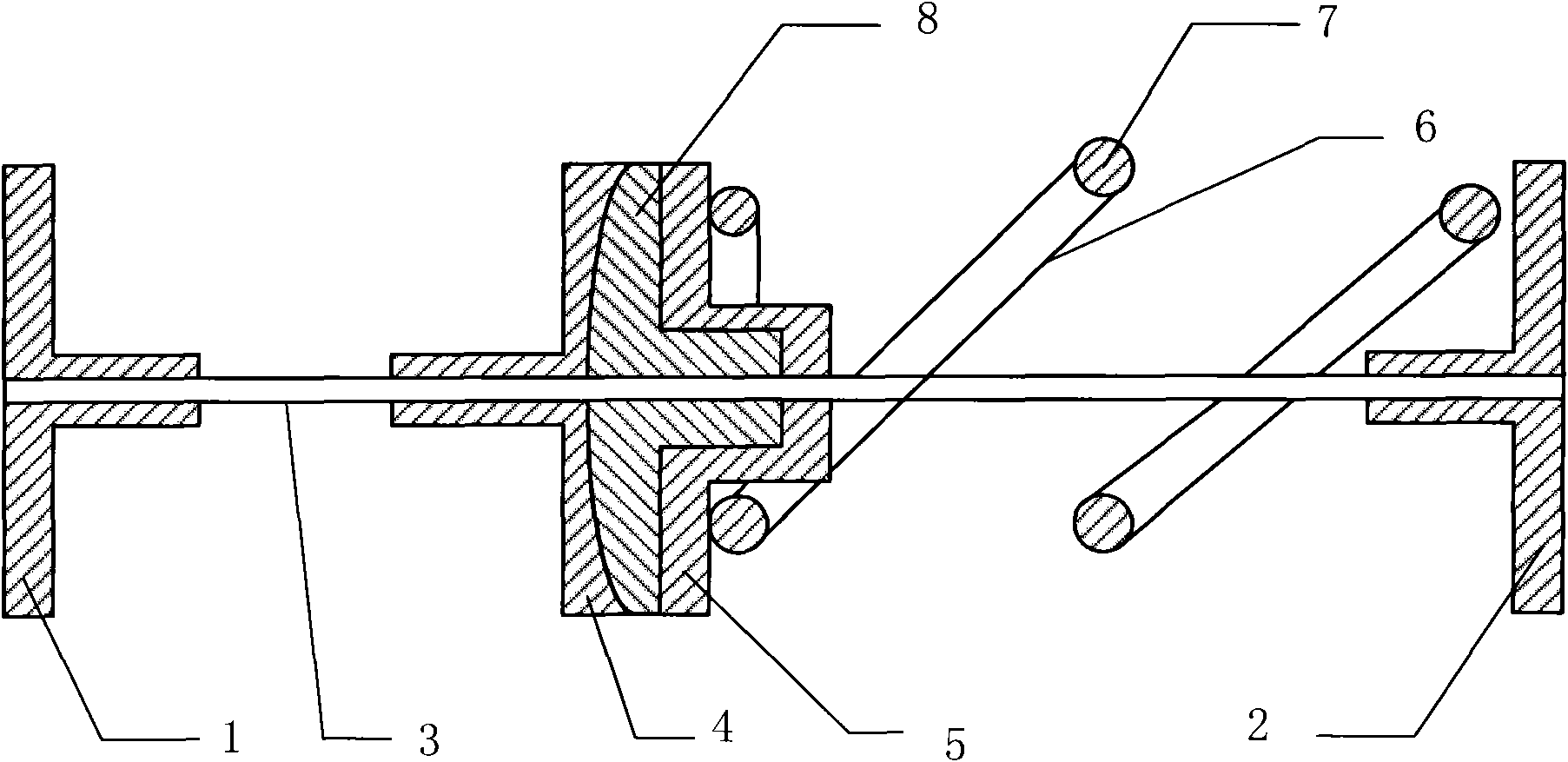

[0024] Such as figure 1 The hybrid shock absorber for a fully automatic washing machine shown includes an upper snap ring 1 and a lower snap ring 2, which is different in that a guide rail steel wire is threaded between the upper snap ring 1 and the lower snap ring 2 3. Specifically, a guide assembly is sheathed on the periphery of the guide rail steel wire 3 , and the guide assembly includes a main guide assembly 4 and a secondary guide assembly 5 . Moreover, shock absorbing assemblies are arranged in the main guide assembly 4 and the auxiliary guide assembly 5 .

[0025] As far as a preferred embodiment of the present invention is concerned, in order to further improve the effect of shock absorption, the guide rail steel wire 3 used in the present invention is extended with an auxiliary steel wire 6 . At the same time, an elastic component is sheathed on the auxiliary steel wire 6, and the auxiliary steel wire 6 and the elastic component constitute an auxiliary buffer com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com