Method and device for measuring channel flow coefficient of pressurized cabin of passenger aircraft

A channel flow and flow measurement technology, which is applied in the direction of measuring devices, detecting fluid flow by measuring differential pressure, volume/mass flow generated by mechanical effects, etc., can solve structural and interior design weight redundancy waste, influence verification, structure and interior strength assessment can not meet the requirements, etc., to improve the forward design ability, avoid redundant waste, and improve the effect of iterative input ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

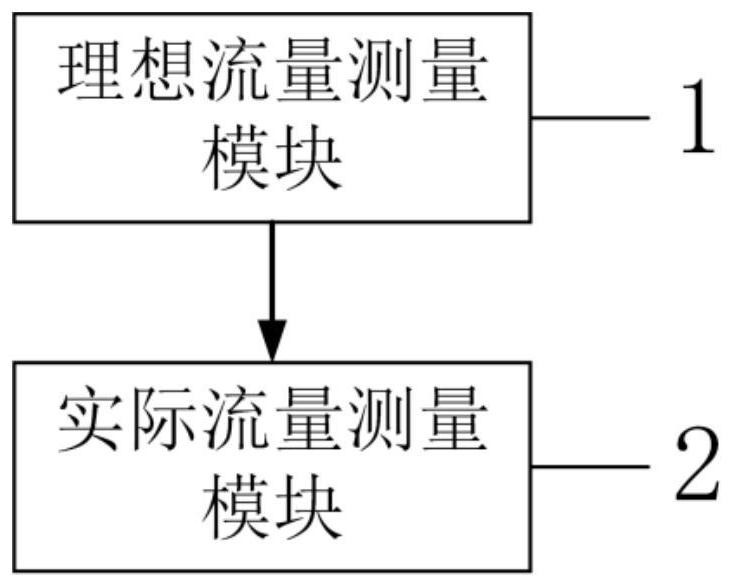

[0039] See figure 1 , figure 1 It is a schematic diagram of a device module for measuring the channel flow coefficient of a pressurized cabin of an airliner provided by an embodiment of the present invention. An embodiment of the present invention provides a device for measuring the flow coefficient of the pressurized cabin channel of a passenger aircraft, including an ideal flow measurement module 1 and an actual flow measurement module 2, wherein,

[0040] The ideal flow measurement module 1, the ideal flow measurement module 1 includes a test chamber, which is used to adjust the inlet pressure and outlet pressure of the test chamber. When the inlet pressure of the test chamber reaches the inlet target pressure value and the outlet pressure reaches the outlet target pressure value, respectively measure The inlet pressure and outlet pressure of the test chamber, and the measurement of the gas temperature in the test chamber to obtain the ideal flow m according to the inlet p...

Embodiment 2

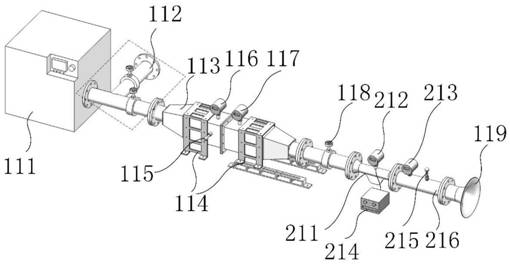

[0051] See figure 2 , figure 2 It is a structural schematic diagram of a negative pressure device for measuring the channel flow coefficient of a pressurized cabin of an airliner provided by an embodiment of the present invention. When the test chamber is the first test chamber 113, the ideal flow measurement module 1 includes a screw pump 111, a first valve group 112, a first fixture 114, a first temperature sensor 115, a first outlet pressure sensor 116, a first inlet pressure Sensor 117, second valve group 118 and first bell mouth 119, wherein,

[0052] The screw pump 111 is connected to the first end of the first valve group 112, the first end of the first test chamber 113 is connected to the second end of the first valve group 112, and the second end of the first test chamber 113 is connected to the second end of the second valve group 118. First end, the first fixing device 114 is installed on the outer wall of the first test chamber 113, and the first temperature se...

Embodiment 3

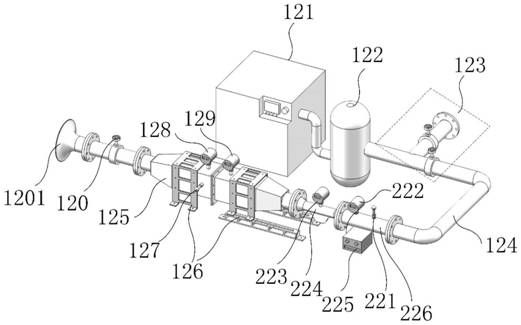

[0067] See Figure 5 , Figure 5 It is a structural schematic diagram of a positive pressure device for measuring the channel flow coefficient of a pressurized cabin of an airliner provided by an embodiment of the present invention. The test chamber is the second test chamber 125, and the corresponding ideal flow measurement module 1 includes a screw compressor 121, an air storage tank 122, a third valve group 123, an outlet pipeline 124, a second fixing device 126, a third temperature sensor 127, a second Three inlet pressure sensors 128, a third outlet pressure sensor 129, a fourth valve group 120 and a second bell mouth 1201, wherein,

[0068] The screw compressor 121 is connected to the first end of the air storage tank 122, the second end of the air storage tank 122 is connected to the first end of the third valve group 123, and the second end of the third valve group 123 is connected to the first end of the outlet pipeline 124 , the second end of the outlet pipe 124 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com