Application of D-A type organic doped crystal afterglow material in counterfeiting prevention

A technology of D-A and acceptor materials, which is applied in the analysis of materials, material excitation analysis, and material analysis through optical means, etc. It can solve the problems of organic long afterglow materials with short afterglow time and materials that cannot be recognized by the naked eye, and achieve good afterglow The effect of luminous properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

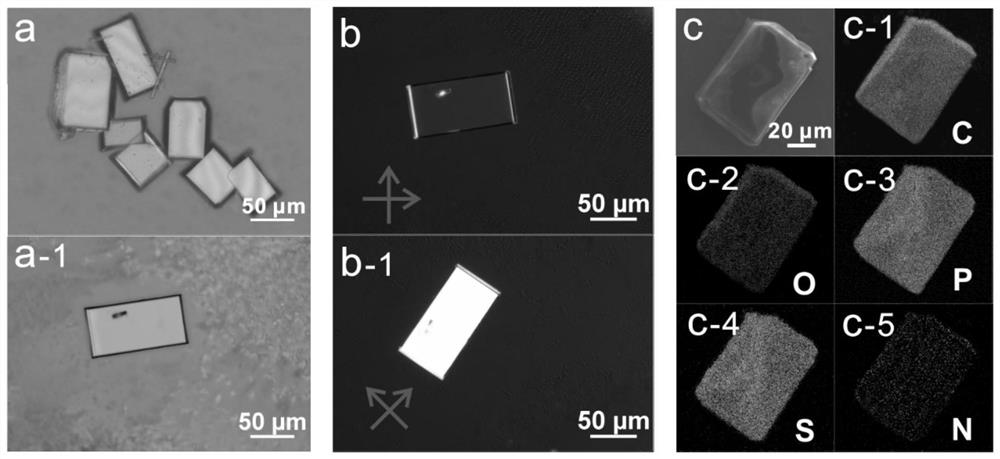

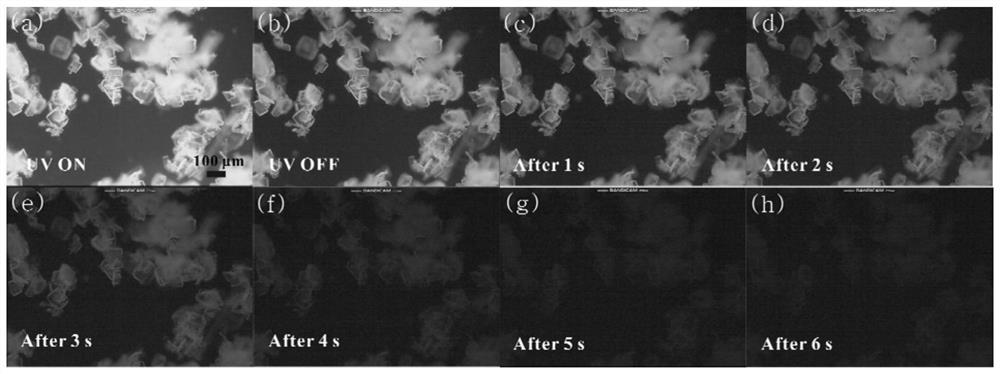

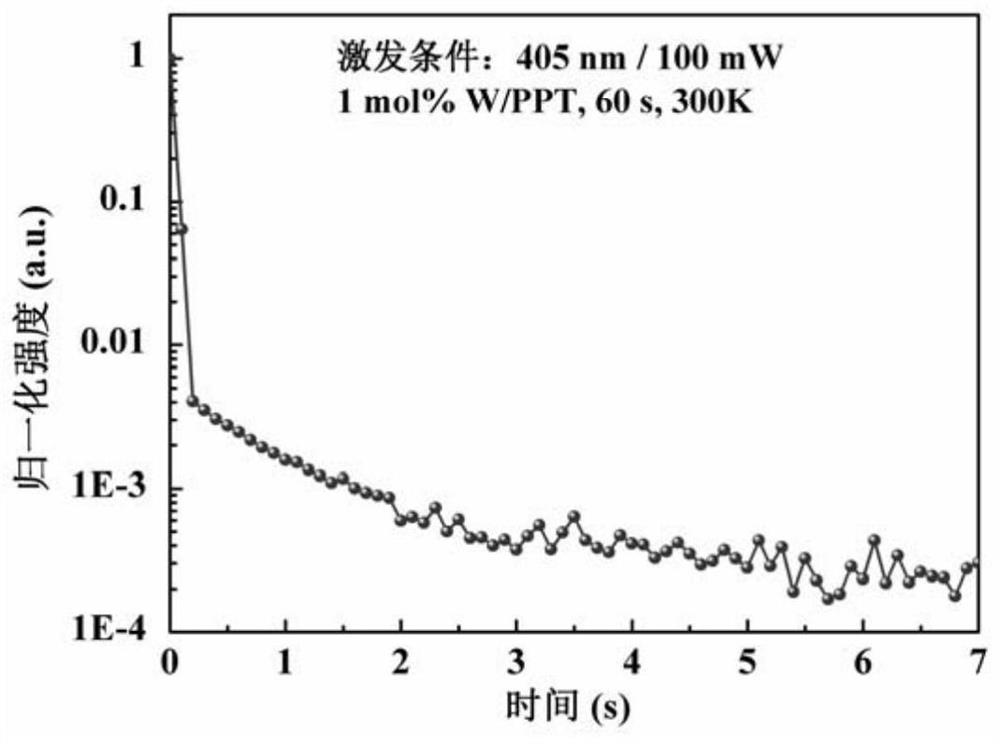

[0088] Application of a D-A type organic doped crystal afterglow material in anti-counterfeiting. In this embodiment, the composition of the D-A type organic doped crystal afterglow material is that the acceptor material A forms regular flaky crystals, and the donor material D is uniformly and freely dispersed on the acceptor material. In the flaky crystal of bulk material A, the preparation method of D-A type organic doped crystal afterglow material comprises the following steps:

[0089] Mix the donor material D (W) and the acceptor material A (PPT) uniformly to obtain a solid powder, add the solid powder to absolute ethanol to obtain a suspension, ultrasonicate the suspension for 1 min, and then place it in an atmospheric environment at room temperature 20-25 °C After standing for 1 hour, the crystals produced at the bottom of the liquid are D-A type organic doped crystal afterglow materials (W / PPT), wherein, calculated by molar ratio, the ratio of donor material D to accept...

Embodiment 2

[0108] Application of a D-A type organic doped crystal afterglow material in anti-counterfeiting. The composition of the D-A type organic doped crystal afterglow material is that the acceptor material A forms regular flaky crystals, and the donor material D is uniformly and freely dispersed in the acceptor material A. between the flaky crystals. The preparation method of D-A type organic doped crystal afterglow material (2M-W / PPT), comprises the following steps:

[0109] Mix the donor material D (2M-W) and the acceptor material A (PPT) uniformly to obtain a solid powder, add the solid powder to anhydrous ethanol to obtain a suspension, ultrasonicate the suspension for 2 minutes, and then place it in a room temperature of 20-25°C After standing for 3 hours in the atmospheric environment, the crystals produced at the bottom of the liquid are D-A type organic doped crystal afterglow materials (2M-W / PPT), in which, calculated by molar ratio, the ratio of donor material D to accept...

Embodiment 3

[0128] Application of a D-A type organic doped crystal afterglow material in anti-counterfeiting. The composition of the D-A type organic doped crystal afterglow material is that the acceptor material A forms regular flaky crystals, and the donor material D is uniformly and freely dispersed in the acceptor material A. between the flaky crystals. The preparation method of the above-mentioned D-A type organic doped crystal afterglow material comprises the following steps:

[0129] Mix the donor material D (4M-W) and the acceptor material A (PPT) uniformly to obtain a solid powder, add the solid powder to anhydrous ethanol to obtain a suspension, ultrasonicate the suspension for 2 minutes, and then place it in a room temperature of 20-25°C After standing for 3 hours in the atmospheric environment, the crystals produced at the bottom of the liquid are D-A type organic doped crystal afterglow materials (4M-W / PPT), wherein, calculated by molar ratio, the ratio of donor material D to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com