Application of d-a Type Organic Doped Crystal Afterglow Materials in Oil

A technology of D-A and acceptor materials, which is applied in the direction of liquid carbon-containing fuel, fuel, petroleum industry, etc., can solve the problems of anti-counterfeiting materials affecting the life of engines or instruments, harsh synthesis conditions, and affecting machine heat dissipation, etc., to achieve good afterglow luminescence performance, The preparation method is simple and the materials are cheap and easy to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

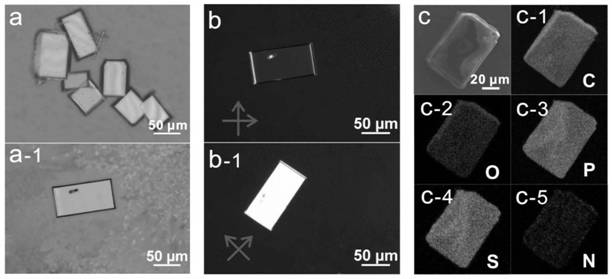

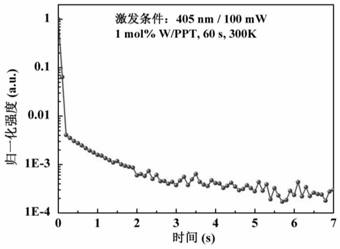

Method used

Image

Examples

Embodiment 1

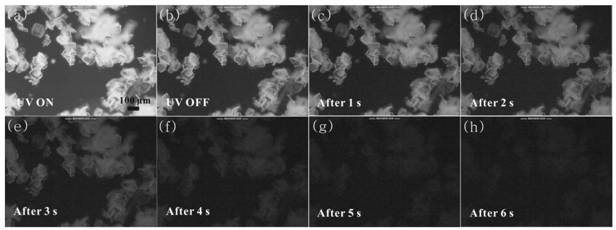

[0077] Put 5mg of D-A type organic doped crystal afterglow material into 10mL Mobil No. 1 motor oil and let it stand for 10 minutes. After the D-A type organic doped crystal afterglow material evenly sinks to the bottom of Mobil No. 1 motor oil, irradiate the D-A of the present invention with a 365nm purple excitation light source. Type organic doped crystal afterglow material, the fluorescence that the crystal of D-A type organic doped crystal afterglow material of the present invention sends is blue (as Figure 4 As shown in a), after the excitation light source is removed, the D-A type organic doped crystal afterglow material emits green afterglow (such as Figure 4 As shown in b), at 6s after the excitation light source is removed, the green afterglow light emitted by the D-A type organic doped crystal afterglow material is still visible to the naked eye (the excitation intensity of the excitation light source is 75mW). Among them, in the first s after the excitation light...

Embodiment 2

[0091] Put 5g of D-A type organic doped crystal afterglow material into 10mL Mobil No. 1 engine oil and let it stand for 10 minutes. After the D-A type organic doped crystal afterglow material evenly sinks to the bottom of Mobil No. 1 engine oil, irradiate the D-A of the present invention with a 365nm purple excitation light source. Type organic doped crystal afterglow material (excitation intensity is 75mW), the fluorescence that the crystal of D-A type organic doped crystal afterglow material of the present invention sends is blue (such as Figure 5 As shown in a), after the excitation light source is removed, the crystal of the D-A type organic doped crystal afterglow material emits green afterglow light, and at the 4th second after the excitation light source is removed, the D-A type organic doped crystal afterglow material still emits a light that can be recognized by the naked eye Afterglow light, wherein, in the first s after the excitation light source is removed, the a...

Embodiment 3

[0104] Put 5mg of D-A type organic doped crystal afterglow material into 10mL Mobil No. 1 motor oil and let it stand for 10 minutes. After the D-A type organic doped crystal afterglow material evenly sinks to the bottom of Mobil No. 1 motor oil, irradiate the D-A of the present invention with a 365nm purple excitation light source. Type organic doped crystal afterglow material (excitation intensity is 75mW), the fluorescence that the crystal of D-A type organic doped crystal afterglow material of the present invention sends is blue (such as Figure 7 As shown in a), after the excitation light source is removed, the crystal of the D-A type organic doped crystal afterglow material emits green afterglow light, and at the 4th second after the excitation light source is removed, the D-A type organic doped crystal afterglow material still emits a light that can be recognized by the naked eye Afterglow light, wherein, in the first s after the excitation light source is removed, the af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com