Afterglow slurry based on d-a type organic doped crystal afterglow material and its preparation method and application

A D-A, acceptor material technology, applied in the direction of organic chemistry, organic chemistry, luminescent materials, etc., can solve the problems of limiting organic afterglow slurry, loss of afterglow performance, short afterglow time, etc., and achieve good afterglow luminescence performance and stable performance Good, easily degradable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0084] A preparation method for afterglow slurry, comprising the following steps:

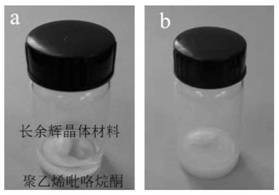

[0085] In the glove box, under nitrogen, add 600mg PVP (polyvinylpyrrolidone) and M mg D-A type organic doped crystal afterglow material (W / PPT) into 3mL absolute ethanol, stir for 6h, and make PVP, D-A type organic doped Mix the mixed crystal afterglow material and absolute ethanol evenly to obtain a white paste slurry. The value of M is detailed in Table 1.

[0086] Table 1

[0087] Example M value (unit: mg) Example 1 500 Example 2 400 Example 3 300 Example 4 200

[0088] In Examples 1-4, the preparation method of D-A type organic doped crystal afterglow material comprises the following steps:

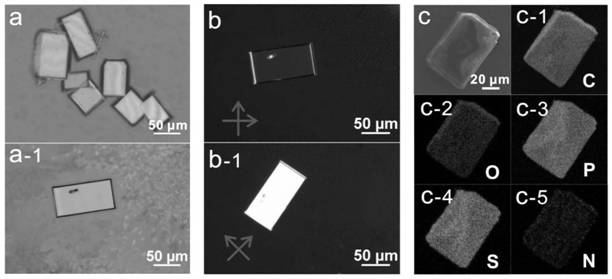

[0089] Mix the donor material D (W) and the acceptor material A (PPT) uniformly to obtain a solid powder, add the solid powder to absolute ethanol to obtain a suspension, ultrasonicate the suspension for 1 min, and then place it in an atmospheric environment...

Embodiment 1

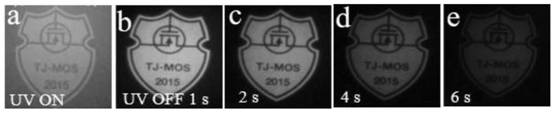

[0103] The state of the controllable pattern printed by the afterglow paste obtained in Example 1 when it is not excited by the excitation light is as follows: Figure 9 shown. After printing, the controllable pattern is transparent without any trace of printing. Under the excitation of 365nm purple light (excitation intensity is 75mW), the fluorescent color emitted by the controllable pattern on the substrate is blue, such as image 3 As shown in a; the excitation light source is removed after the purple light is excited for 1 second, and the controllable pattern on the substrate will show a clear green afterglow, as shown in image 3 As shown in b; in the 2s after the excitation light source is removed, the afterglow brightness of the controllable pattern on the substrate is strong, as shown in image 3 as shown in c;

[0104] At 4s after removing the excitation light source, the afterglow of the controllable pattern on the substrate is still obvious as image 3 shown in...

Embodiment 5

[0109] A preparation method for afterglow slurry, comprising the following steps:

[0110] In the glove box, under nitrogen, add 600mg PVP (polyvinylpyrrolidone) and 500mg D-A type organic doped crystal afterglow material (2M-W / PPT) into 3mL absolute ethanol, stir for 6h, and make PVP, D-A type organic The doped crystal afterglow material is mixed evenly with absolute ethanol to obtain a white paste slurry.

[0111] The preparation method of D-A type organic doped crystal afterglow material (2M-W / PPT) in embodiment 5 comprises the following steps:

[0112] Mix the donor material D (2M-W) and the acceptor material A (PPT) uniformly to obtain a solid powder, add the solid powder to anhydrous ethanol to obtain a suspension, ultrasonicate the suspension for 2 minutes, and then place it in a room temperature of 20-25°C After standing for 3 hours in the atmosphere, the crystals produced at the bottom of the liquid are D-A type organic doped crystal afterglow materials (2M-W / PPT). C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com