Double swirl type air purifier

An air purifier, eddy current technology, applied in the direction of air quality improvement, air conditioning system, air flow control components, etc., can solve the problems of multiple humidity and hygiene, small contact area, dehumidification problems, etc., to achieve easy maintenance and management, high capture efficiency , Easy to lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, a detailed description will be given with reference to a preferred embodiment of the present invention.

[0042] For reference, the structures of the present invention described below that are the same as those of the prior art can refer to the above-mentioned prior art, and separate detailed descriptions are omitted.

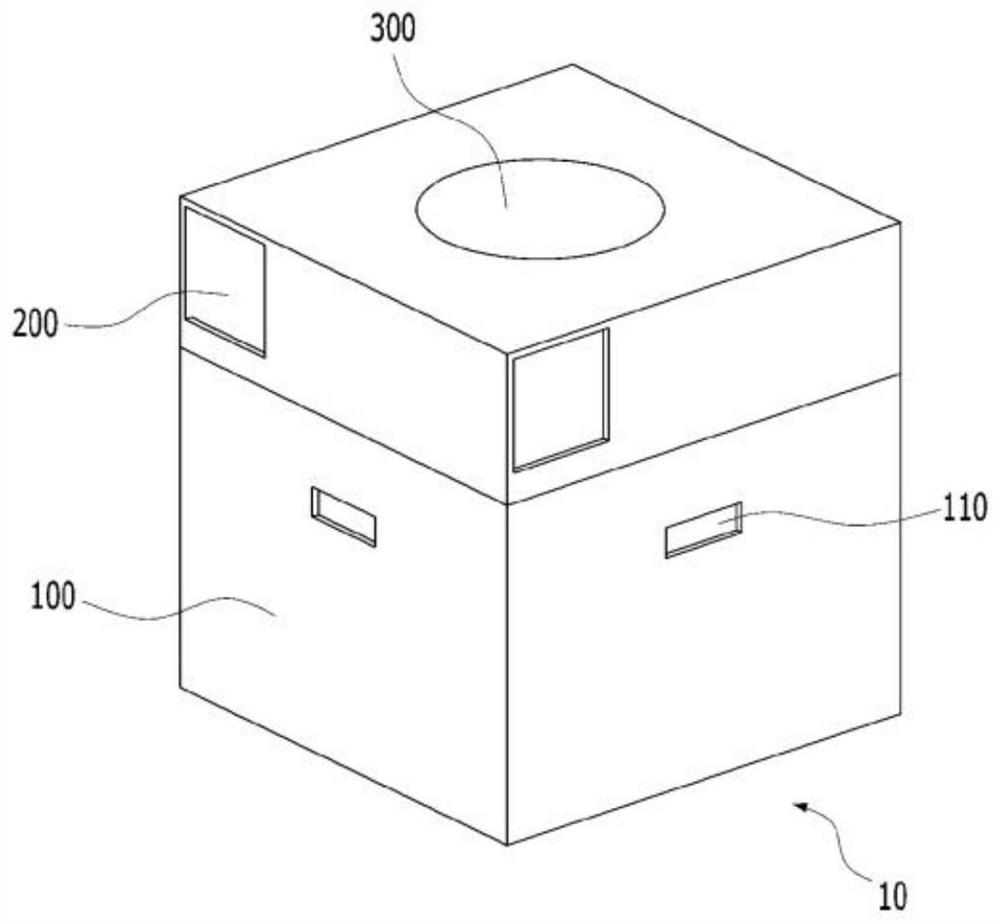

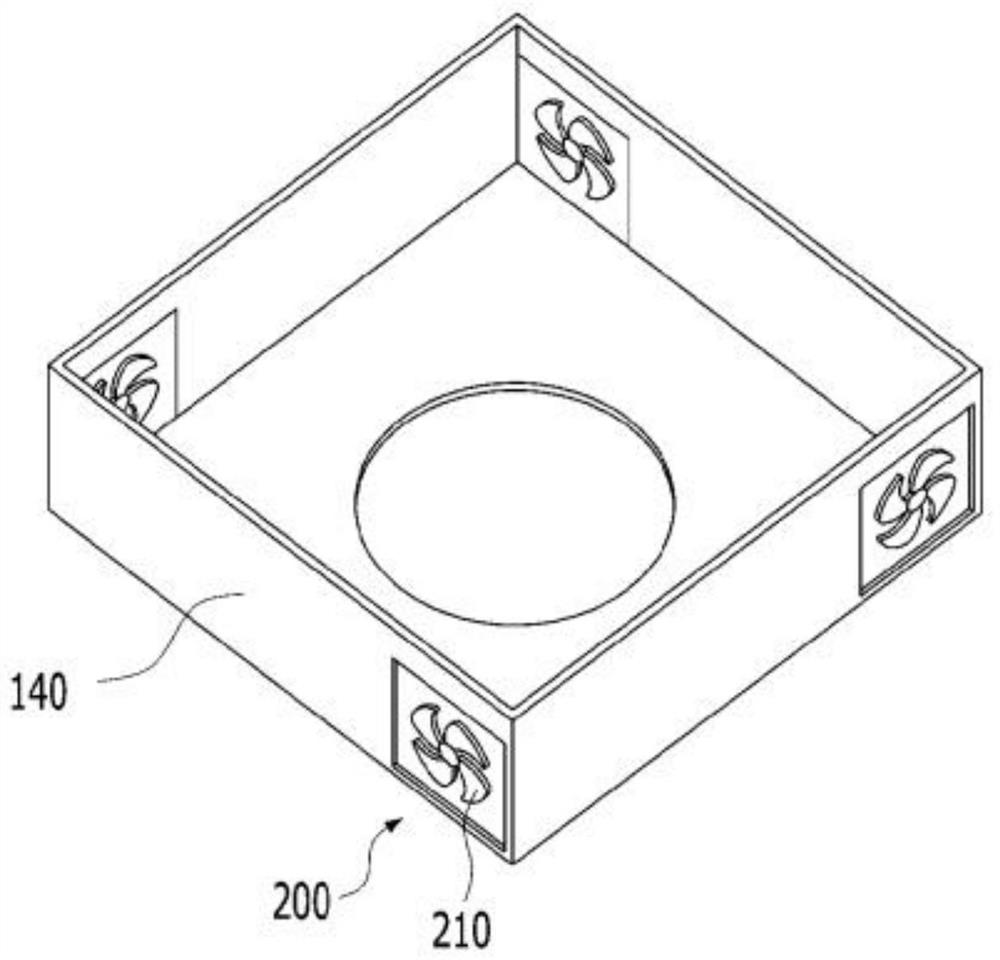

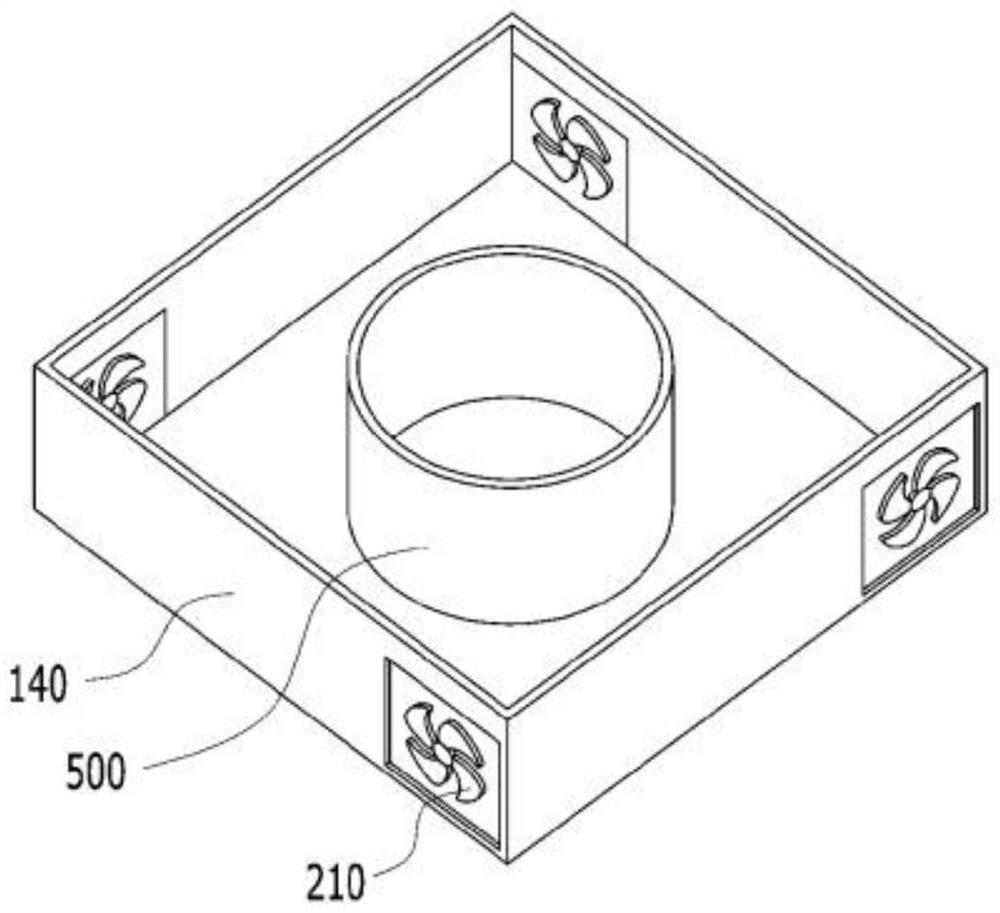

[0043] FIG. 1 is a perspective view of a double vortex air cleaner according to an embodiment of the present invention, and FIGS. 2a and 2b are exploded views of a cover of the double vortex air cleaner according to an embodiment of the present invention.

[0044] As shown in FIG. 1 , FIG. 2 a , and FIG. 2 b , the double vortex air cleaner 10 of the present invention includes a main body 100 , a suction part 200 , a discharge part 300 and a rotating part 400 disposed on one side of the main body.

[0045] The main body part 100 is used as a storage part containing a liquid, and the liquid is used to purify the air introduced inside the doubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com