Efficient washing equipment for rice processing

A rice processing and high-efficiency technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of rice and washing water swirling, suspended debris is difficult to clean, and coverage is not comprehensive , to achieve the effect of ingenious design, avoiding swirling phenomenon and improving the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

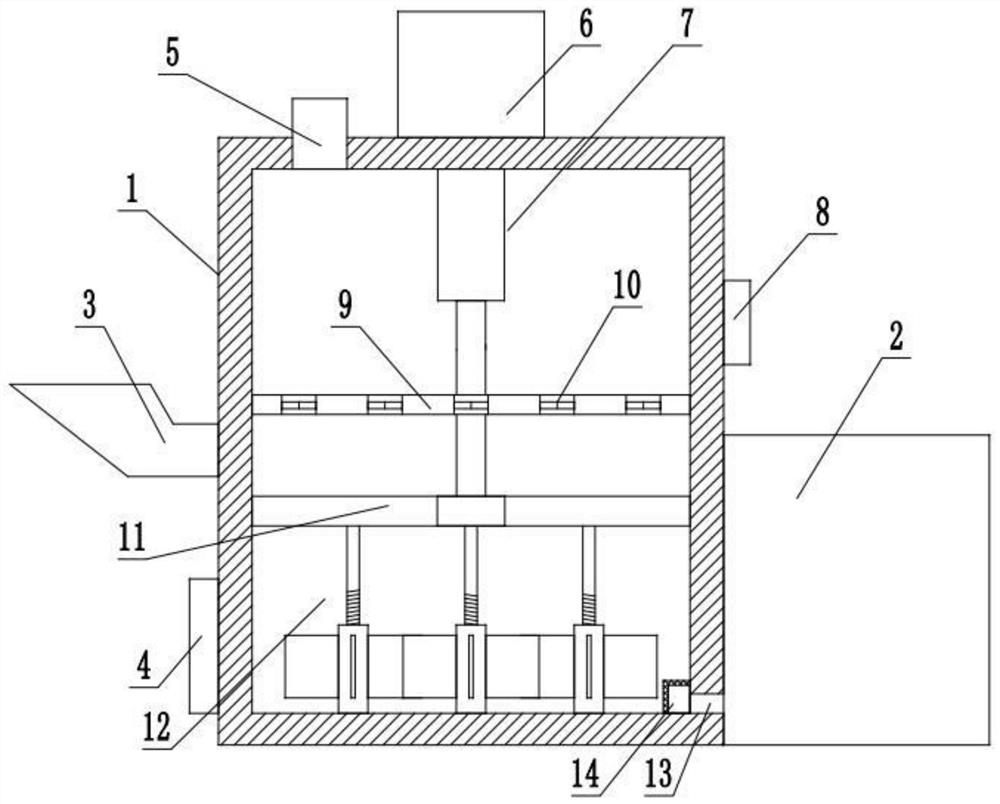

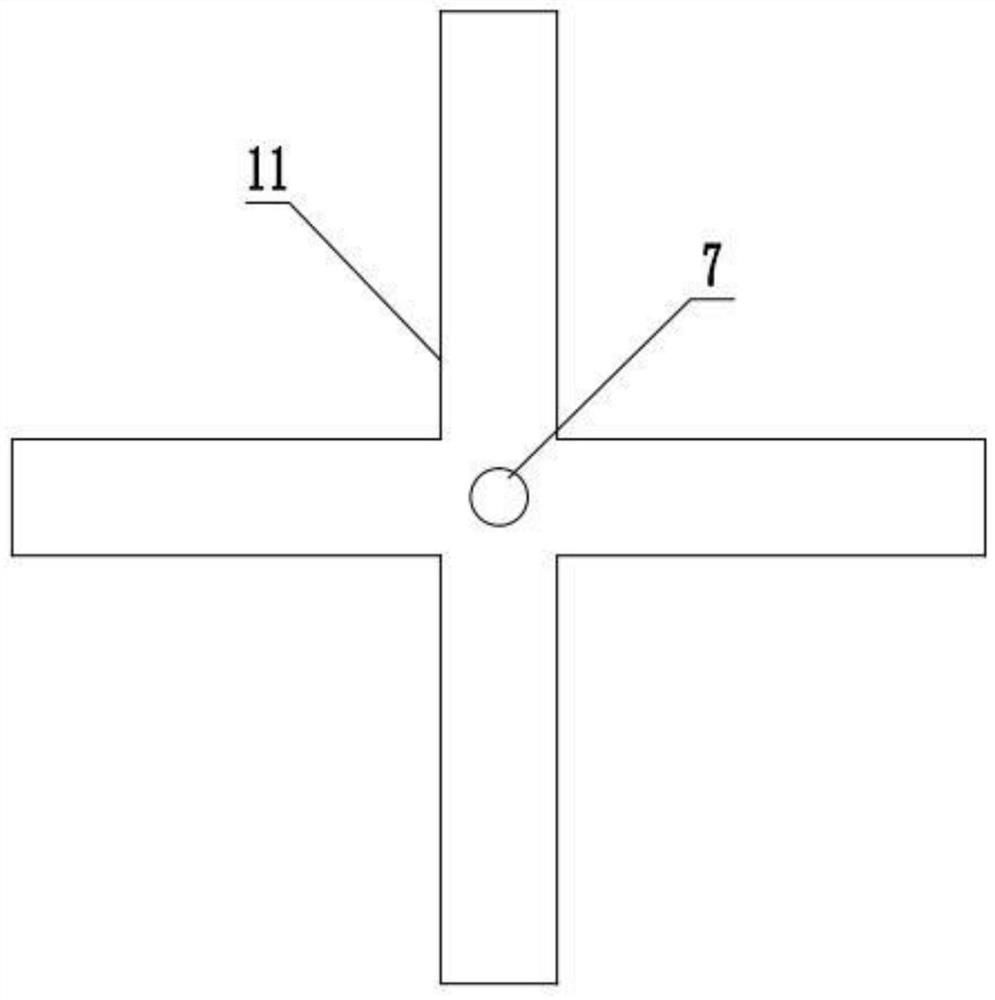

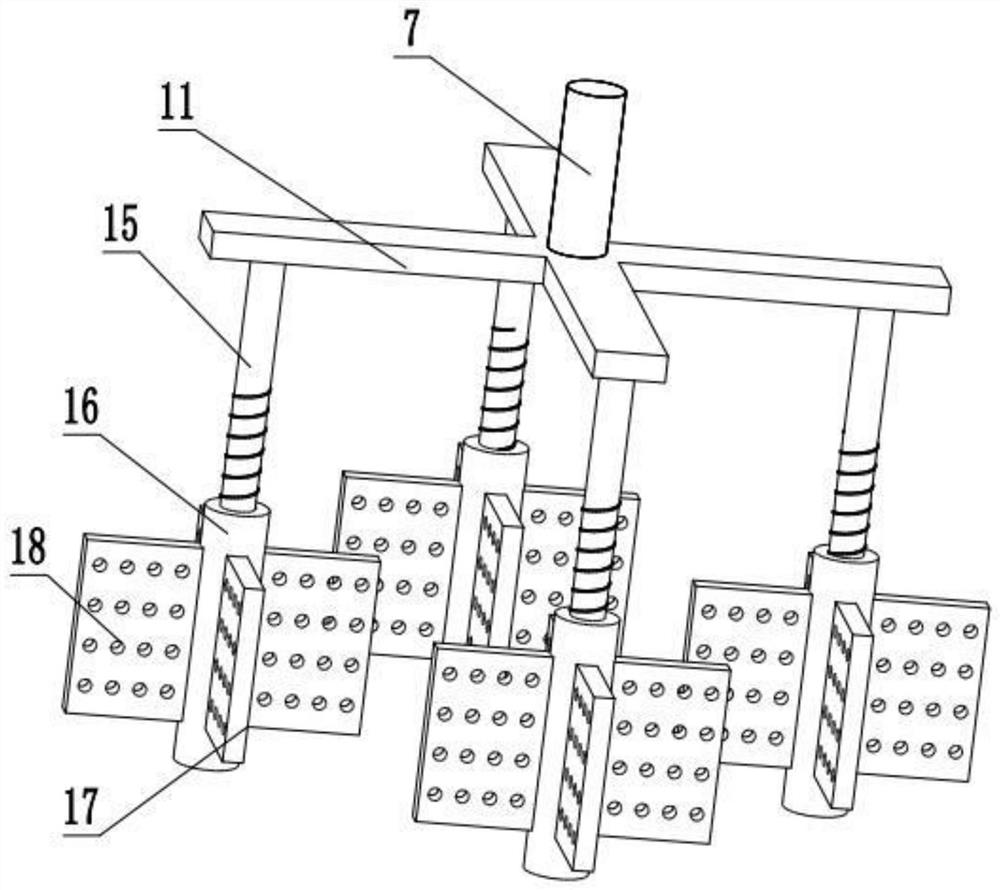

[0019] see Figure 1-4 , a high-efficiency elutriation equipment for rice processing, comprising an elutriation box 1 and a sewage tank 2 arranged side by side, an input hopper 3 and a discharge door 4 are provided on the side of the elutriation box 1, and water replenishment is provided on the top of the elutriation box 1 The pipe 5 is used to supplement the elutriation water. The input hopper 3 and the discharge door 4 are located on the same side of the elutriation box 1, the input hopper 3 is located in the center of the side of the elutriation box 1, and the discharge door 4 is located at the bottom of the side of the elutriation box 1. The washing tank 1 and the sewage tank 2 are connected through the transfer channel 13 located at the bottom of the washing tank 1 and the sewage tank 2. When washing the rice, the rice enters the washing tank 1 through the feeding hopper 3 for washing. The finished sewage is collected in the sewage tank 2 through the transfer pipe, and th...

Embodiment 2

[0023] On the basis of Embodiment 1, the upper part of the outer wall of the elutriation box 1 is provided with a miscellaneous door 8, and the miscellaneous door 8 is used to clean up the impurities accumulated on the lifting plate 9; the inner bottom of the elutriation box 1 is provided There is an interception box 14, and the interception box 14 is set outside the transfer channel 13. When the elutriation process is completed, the sewage is first discharged through the transfer channel 13. During the discharge process, the rice is intercepted by the interception net to prevent the rice from entering the sewage tank 2 Inside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com