Tube punching die with improved structure

A technology of structural improvement and punching die, applied in the direction of perforation tools, metal processing equipment, manufacturing tools, etc., can solve the problems of easily stuck in vertical holes, deformation of mandrels, difficult to fall out, etc. The effect of cracking, improving strength and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

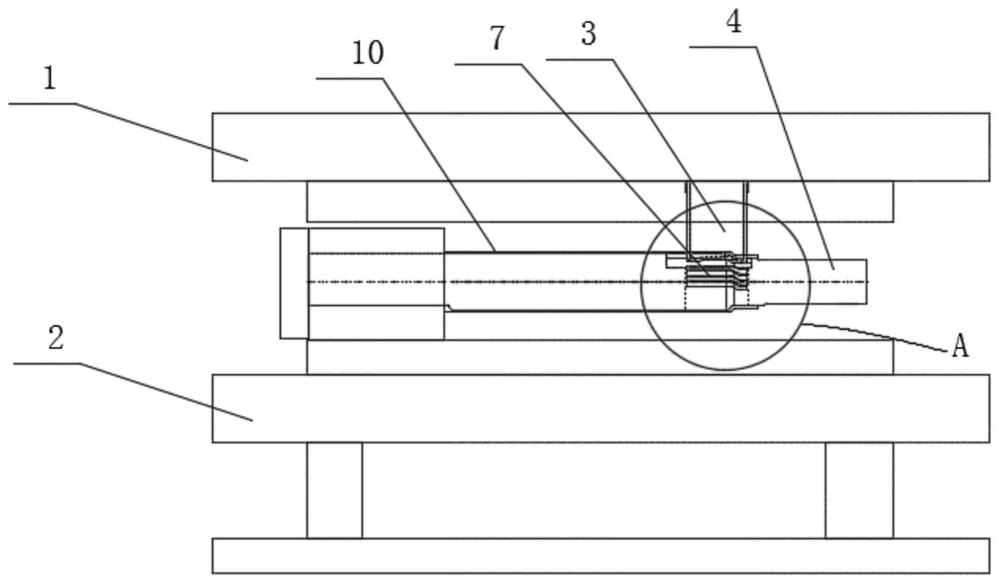

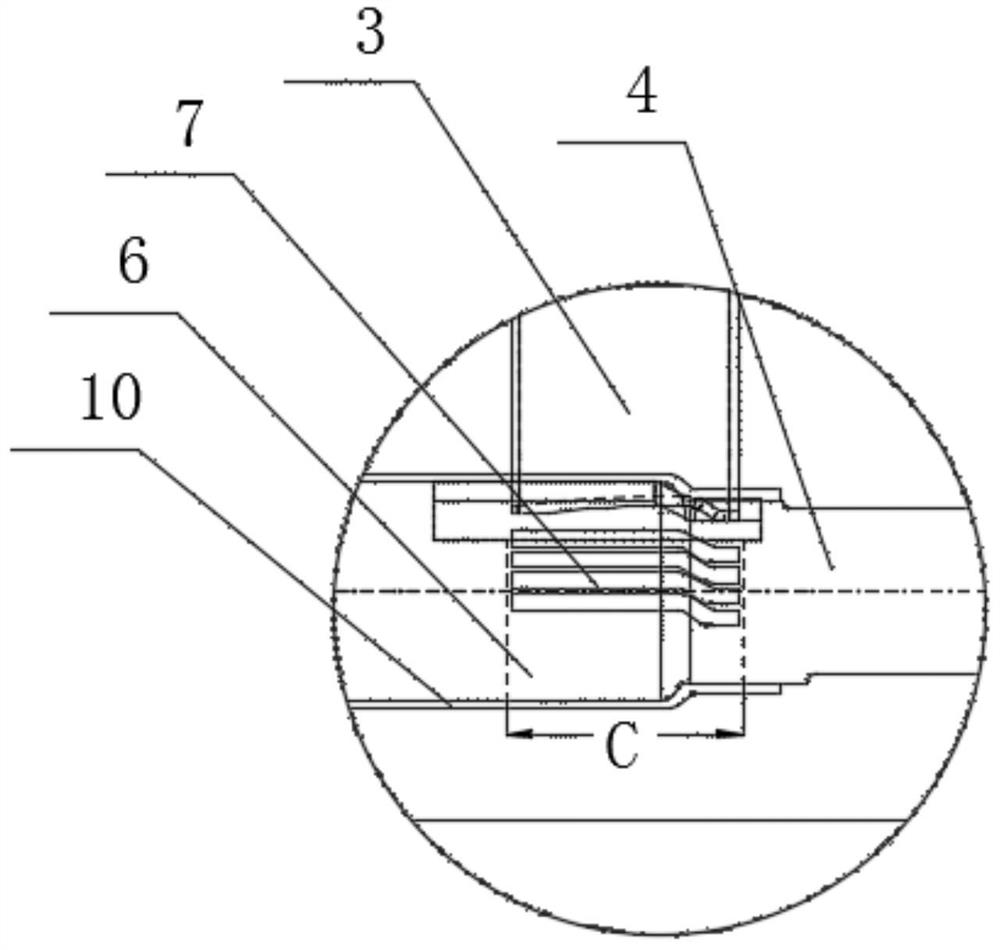

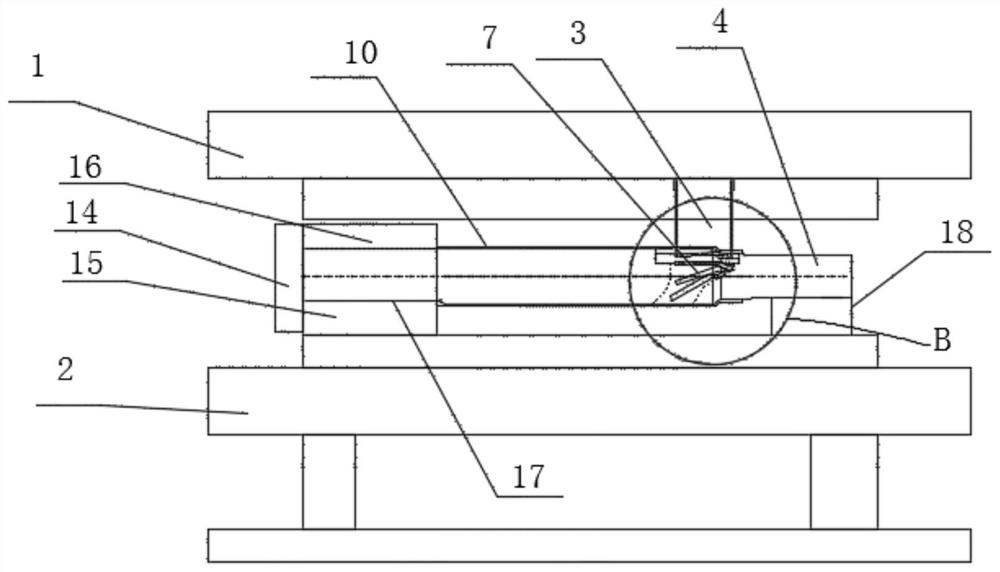

[0023] Example: A pipe punching die with an improved structure, comprising an upper die 1, a lower die 2, a punch 3, a core rod 4, and a core rod positioning device. The upper die 1 can move up and down and is located directly above the lower die 2. , The punch 3 is fixedly installed on the upper mold 1, the core rod positioning device is installed on the lower mold 2, the core rod positioning device can fix the core rod 4 on the lower mold 2, and the pipe to be punched can just be sleeved on On the outer circumference of the core rod 4, the core rod 4 is provided with a die hole 5 and a blanking hole 6. The punch 3 can be inserted into the die hole 5 of the core rod 4. The side wall of the punch 3 and the core rod 4 The side wall of the die hole 5 is formed with a cutting edge, the upper end of the blanking hole 6 and the lower end of the die hole 5 are directly connected to form a radial hollow structure penetrating the core rod 4, and a side wall of the blanking hole 6 is for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com