Full-automatic film sheet forming device

A molding device, fully automatic technology, applied in the direction of static electricity, metal processing, electrical components, etc., can solve the problems of low cutting efficiency, reduced efficiency, affecting film arrangement and packaging, etc., to ensure stability, increase yield, and facilitate Finishing and packaging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

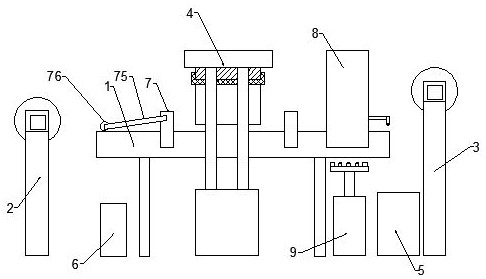

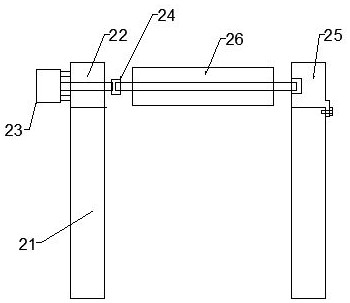

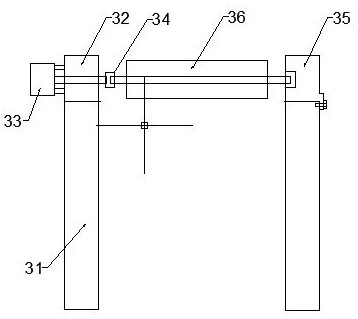

[0025] like Figure 1-6 As shown: this embodiment is a fully automatic diaphragm forming device, including a workbench 1, a conveying mechanism 2 and a winding mechanism 3 respectively arranged on the left and right sides of the workbench 1, and a punching and shearing forming device arranged on the top of the workbench 1. Device 4, the finished product collection box 5 arranged under the side of the workbench 1 close to the winding mechanism 3 and the controller 6 arranged at the bottom of the workbench 1, the conveying mechanism 2 is used to convey the raw material roll to the punching and shearing forming device 4 for punching and forming Afterwards, the waste material is rewound by the rewinding mechanism, and the finished product after punching and shearing falls into the finished product collection box 5; The support plate 42 between the ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com