Construction method for continuous type hanging net rack platform for hyperbolic reticulated shell venue

A technology of reticulated shell venues and construction methods, which is applied to the accessories of scaffolding, the processing of building materials, and the scaffolding supported by house structures, etc., which can solve the problems of long construction period, difficult maintenance, and complicated steel grid structure. , to achieve the effect of convenient and fast construction and dismantling process, strong construction pertinence, and easy promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

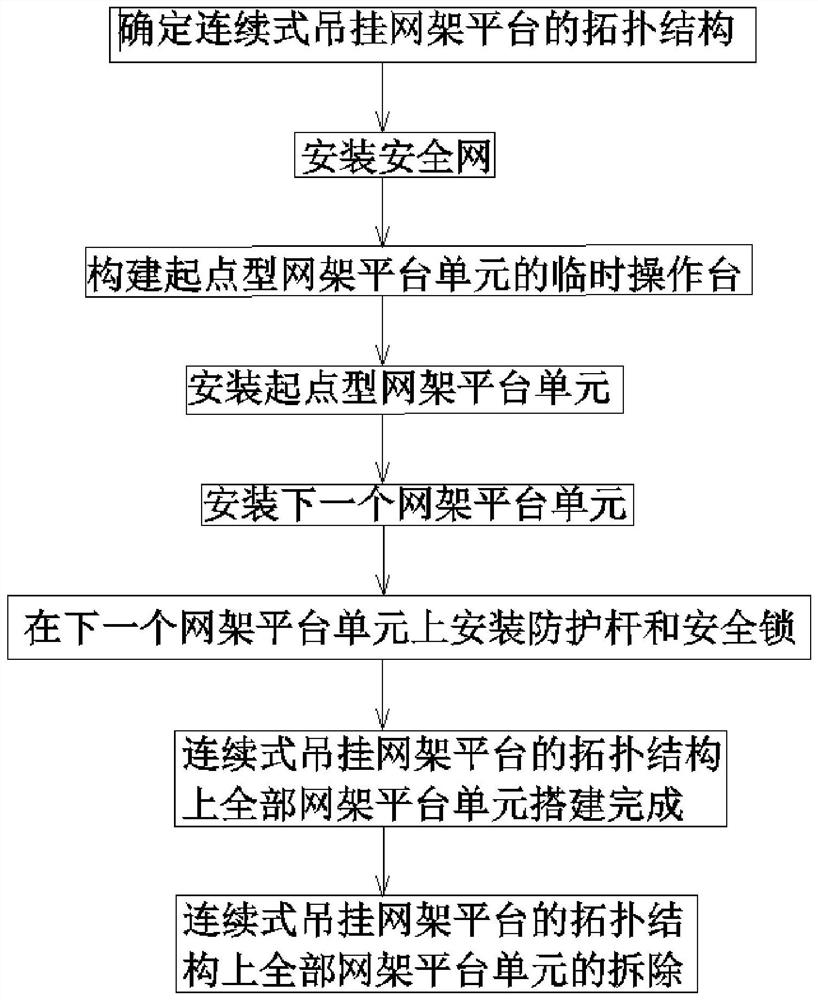

[0059] like Figure 1-Figure 7 Shown, the present invention comprises the following steps:

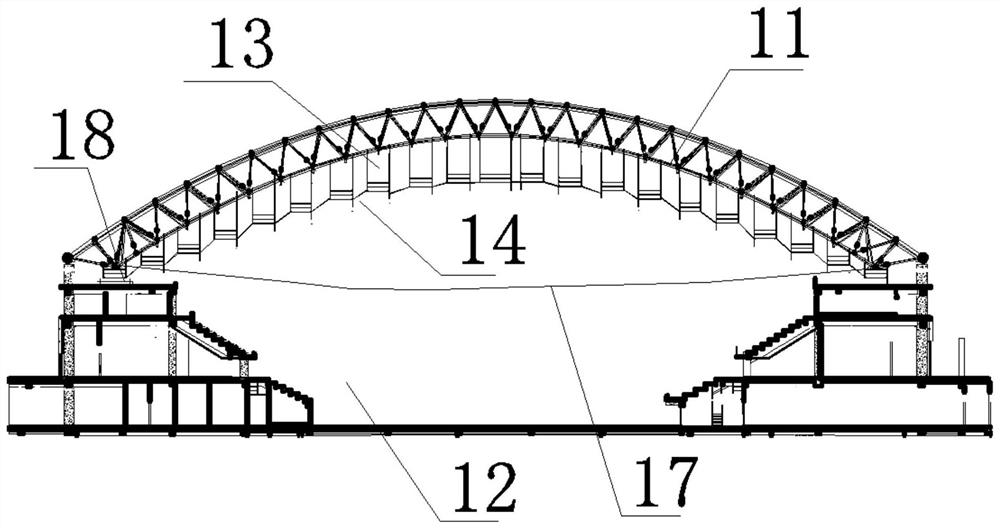

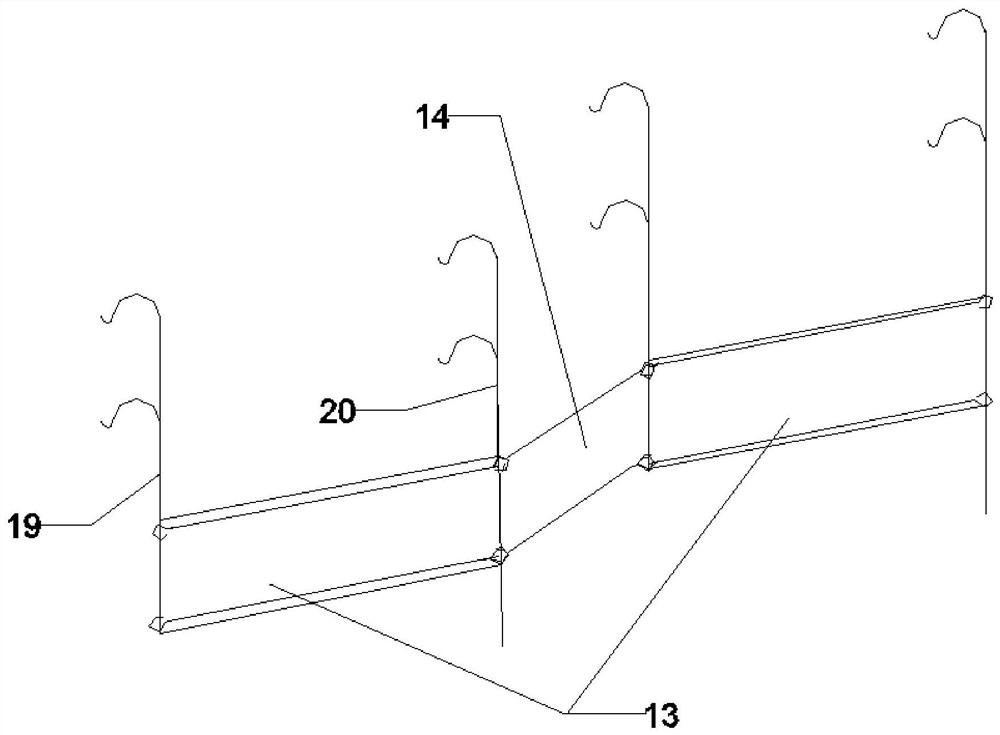

[0060] Step 1. Determine the topological structure of the continuous hanging grid platform: determine the hanging point positions of multiple grid platform units 13 according to the positions to be constructed on the top of the hyperbolic reticulated shell venue 12, and determine the continuous hanging grid according to the principle of optimal path The topological structure of a plurality of network frame platform units 13 in the frame platform;

[0061] like Figure 4 As shown, when the topology of multiple grid platform units 13 in the continuous hanging grid platform is a single-line topology, the continuous hanging grid platform includes sequentially connected start-type grid platform units 13-1 , Transitional grid platform unit 13-2 and terminal grid platform unit 13-3, the number of transitional grid platform units 13-2 is multiple;

[0062] It should be noted that the single...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com