Batch remote upgrading and degrading method and system for machine tool numerical control software

A technology of numerical control software and software upgrade, applied in the field of numerical control machine tools, can solve problems such as increasing the difficulty of software upgrade function development, affecting factory production efficiency, and huge workload, so as to reduce the difficulty of software upgrade development and the consumption and upgrade of machine tool system resources The status is intuitive and unified, which is conducive to the effect of unified management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

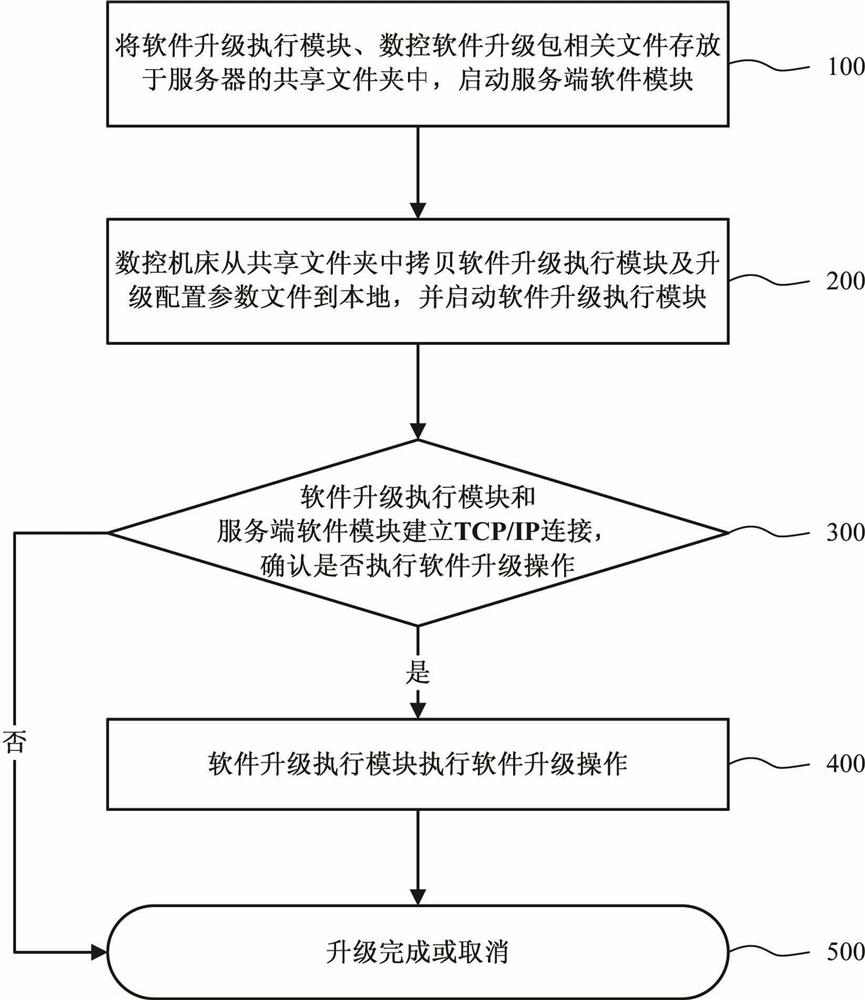

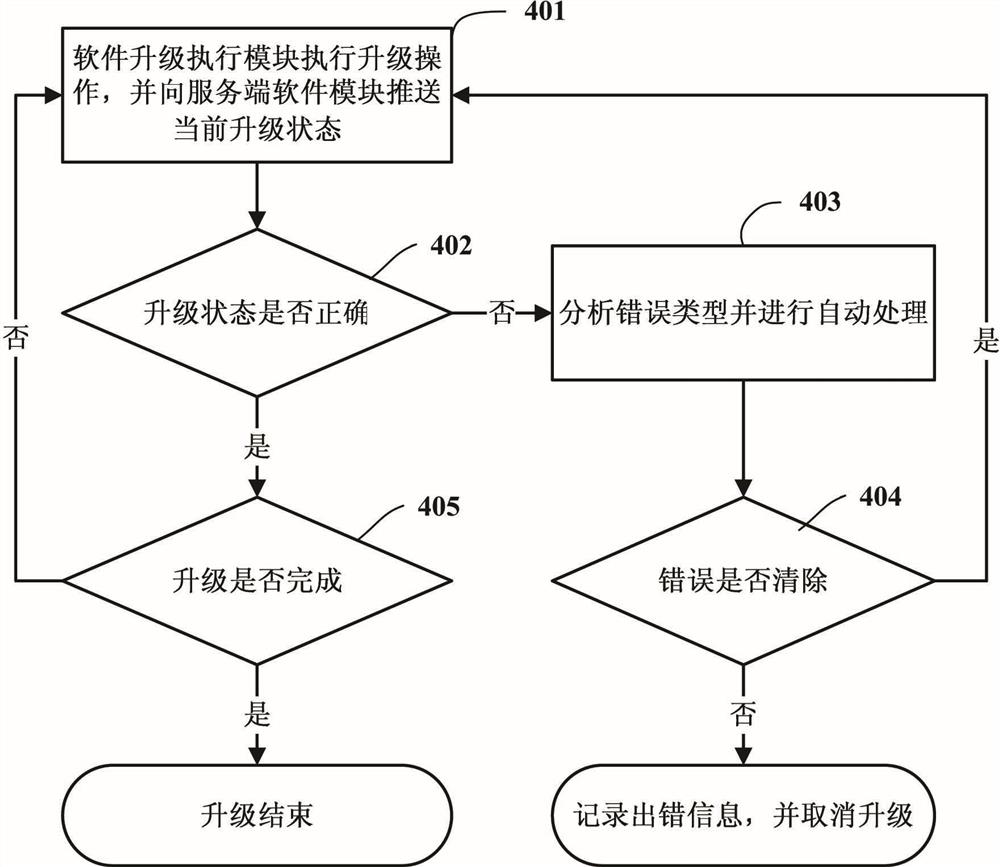

[0029] figure 1 It shows a schematic flow chart of a batch remote upgrading and upgrading method for machine tool numerical control software of the present invention, including the following steps:

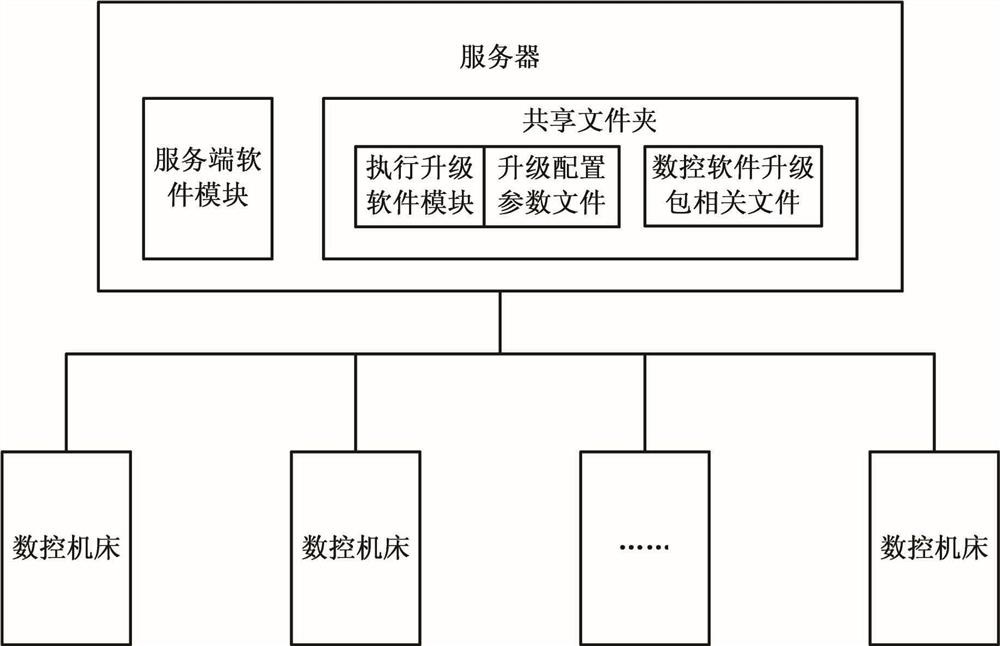

[0030] Step 100, store the relevant files of the software upgrade execution module and the numerical control software upgrade package in the shared folder of the server, the server starts the server software module, generates an upgrade configuration parameter file according to the upgrade target setting parameters and saves it in the designated shared folder Under the directory; the upgrade target includes the ID of the CNC machine tool to be upgraded, the target upgrade version of the CNC software, server configuration, etc.;

[0031] Step 200, the CNC machine tool is started with a system command line program, copying the software upg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com