Pipe cutting device used for cutting line pipe

A technology of pipe cutters and wire pipes, applied in the field of pipe cutters, can solve the problems of high construction cost and waste of labor, and achieve the effects of fast cutting efficiency, avoiding uneven force, and fast and convenient adjustment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

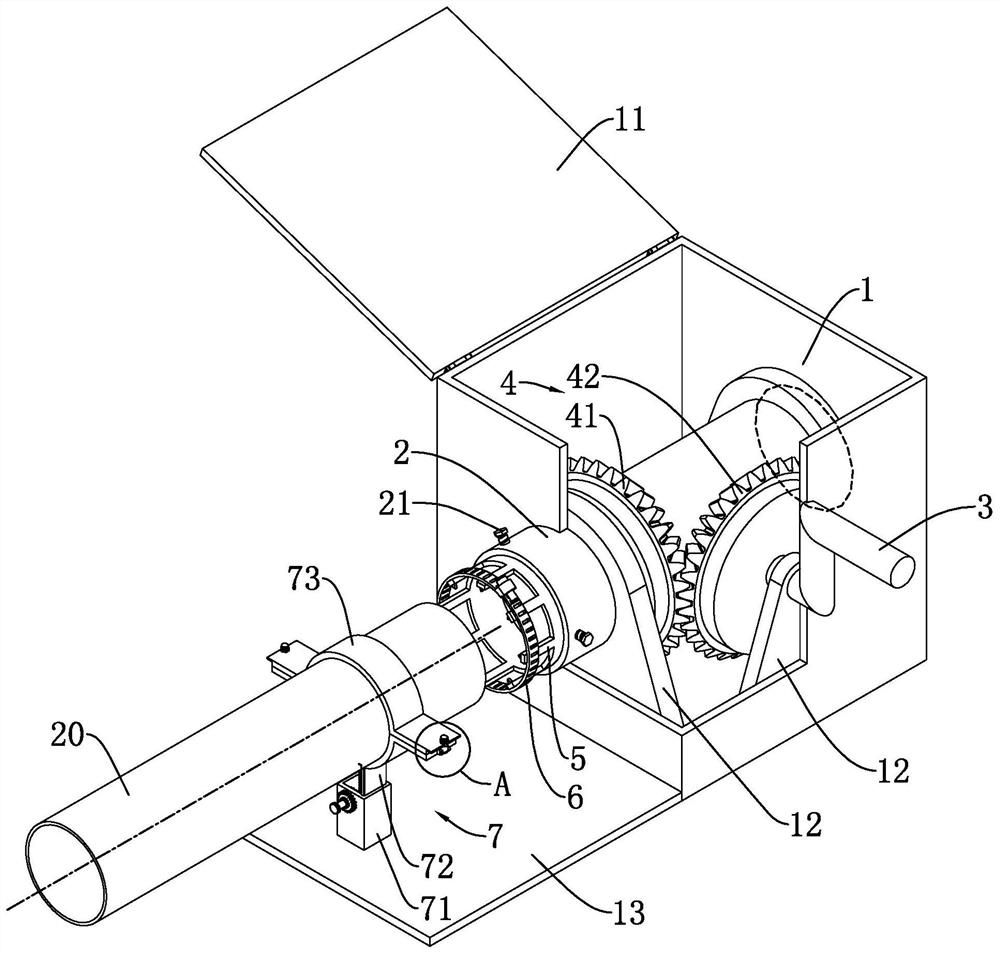

[0036] A pipe cutter for cutting wire pipe, such as figure 1 As shown, it includes a rectangular installation shell 1, the installation shell 1 is hollow inside, its top is open, and a cover 11 that can close or open its top is hinged. The two mutually perpendicular vertical side walls of the installation shell 1 are respectively provided with an installation sleeve 2 and a force-applying handle 3 horizontally, and the installation sleeve 2 penetrates the installation shell 1; a bearing seat 12 is arranged inside the installation shell 1. The part of the casing 2 and the force-applying handle 3 extending into the mounting seat cooperates with the bearing seat 12 to be rotatably mounted on the mounting shell 1 .

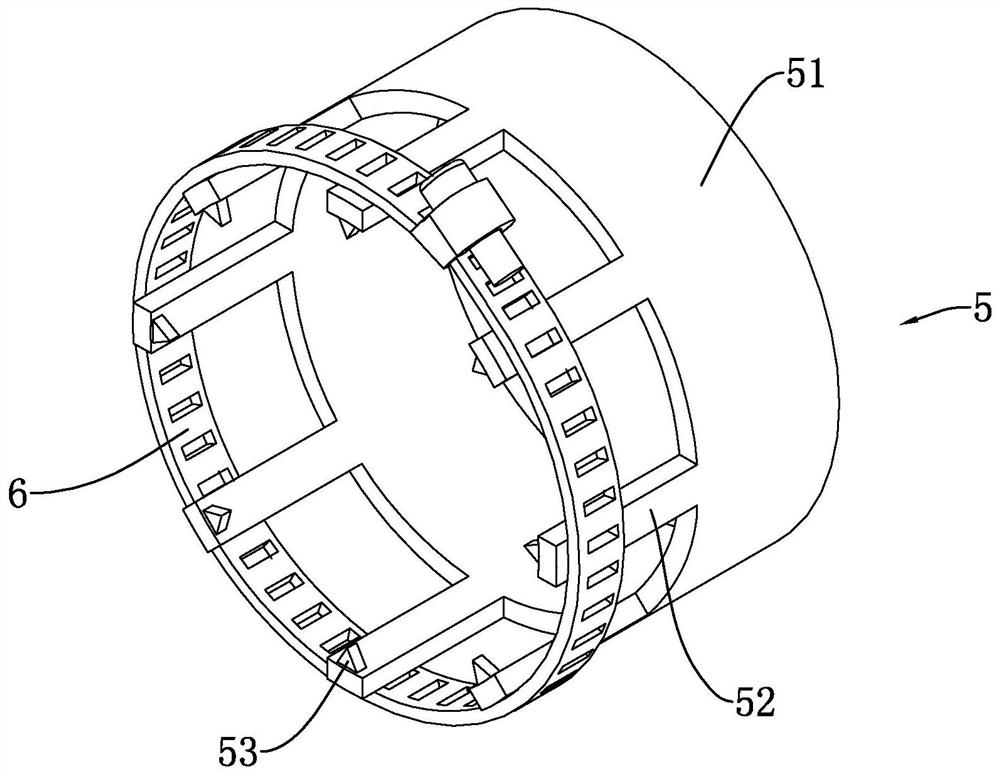

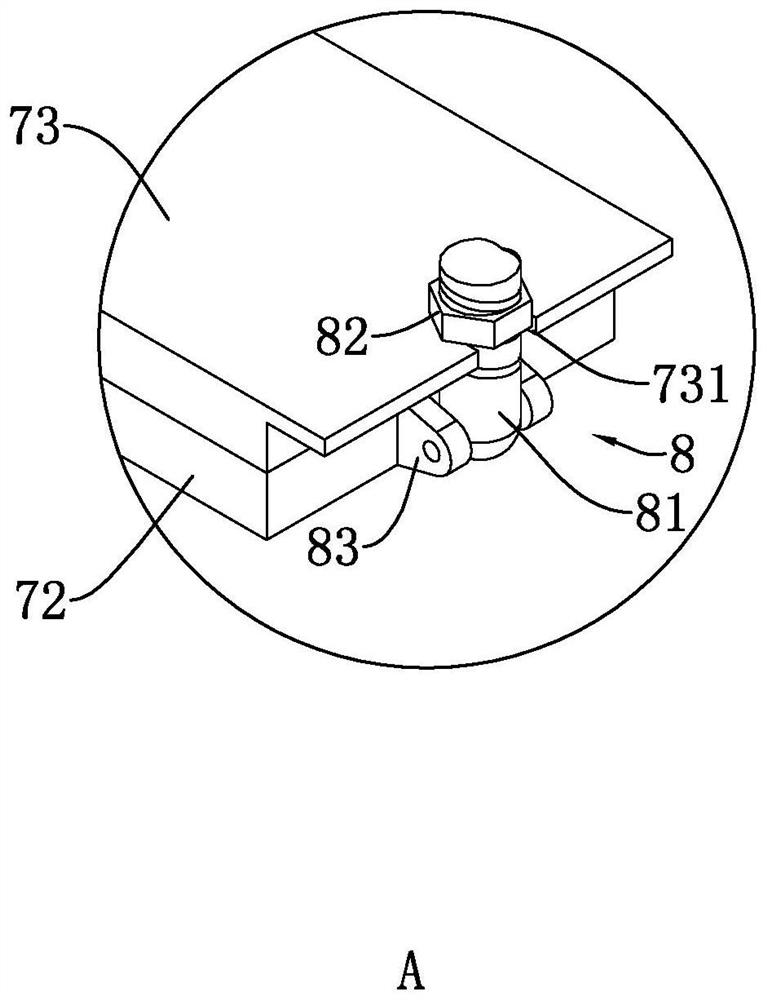

[0037] The inside of the installation shell 1 is also provided with a transmission member 4, the transmission member 4 includes a first bevel gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com