A CNC milling machine with tool breaking protection

A CNC milling machine and knife breaking technology, which is applied in the direction of manufacturing tools, maintenance and safety accessories, metal processing equipment, etc., can solve problems such as tool breakage, waste disposal, and tool injury, so as to reduce injuries and effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

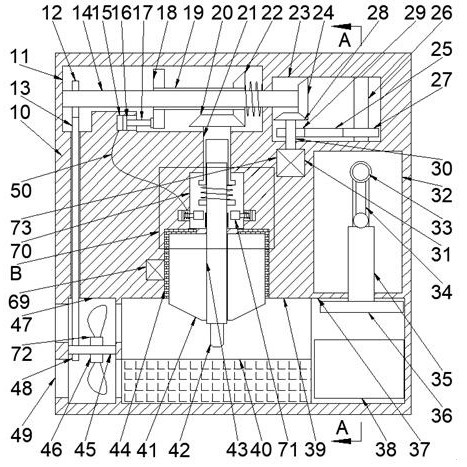

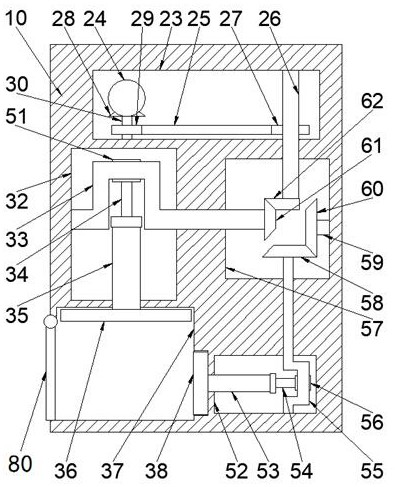

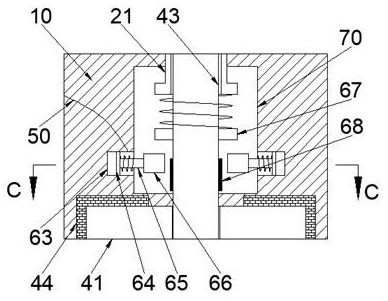

[0015] Combine below Figure 1-4 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0016] A CNC milling machine with tool breakage protection described in conjunction with accompanying drawings 1-4, includes a body 10 and a working chamber 39 disposed inside the body 10, the bottom of the working chamber 39 is fixedly provided with a three-axis base 40, the The inside of the body 10 is provided with a protection device 71 above the working chamber 39. The protection device 71 includes a force-bearing block 41 arranged on the top wall of the working chamber 39 and extending into the body 10. The force-bearing block The outer surface of 41 is fixed with a stress sensor 44, the body 10 is equipped with a cylinder 69 on the left side of the stress sensor 44, and the bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com