Preparation process of uvioresistant luggage cloth

A technology of anti-ultraviolet and preparation technology, applied in the direction of improved hand-feeling fiber, wear-resistant fiber, light-resistant fiber, etc., can solve the problems of shortening the service life of bags, aging of bag fabrics, reducing the mechanical strength of bag fabrics, etc., to increase Effects of stability, damage reduction, and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A preparation process of an anti-ultraviolet luggage fabric, comprising the following steps:

[0043] S1: Preparation of cloth loading liquid: add 5kg rutile-type nano-titanium dioxide, 2kg fucoidan, 2kg polydimethylsiloxane, 1kg benzalkonium chloride, 2kg diboron trioxide, 3kg brown algae residue and 3kg water to 20kg polyacrylate Mix evenly;

[0044] S2: Cloth load: adjust the pH of the cloth load solution to 5, and under the condition of temperature of 40 °C, put the polyester fabric into the fabric load solution made by S1 and immerse it for 30 minutes, and then dry to obtain the finished fabric.

[0045] Wherein the preparation steps of the seaweed polysaccharide:

[0046] S1: the brown algae raw material is cleaned and chopped, and the brown algae is extracted by ultrasonic crushing, and the filtrate is suction filtered to obtain the leaching solution and the brown algae residue containing the brown algae polysaccharide;

[0047] S2: adding ethyl acetate into th...

Embodiment 2-8

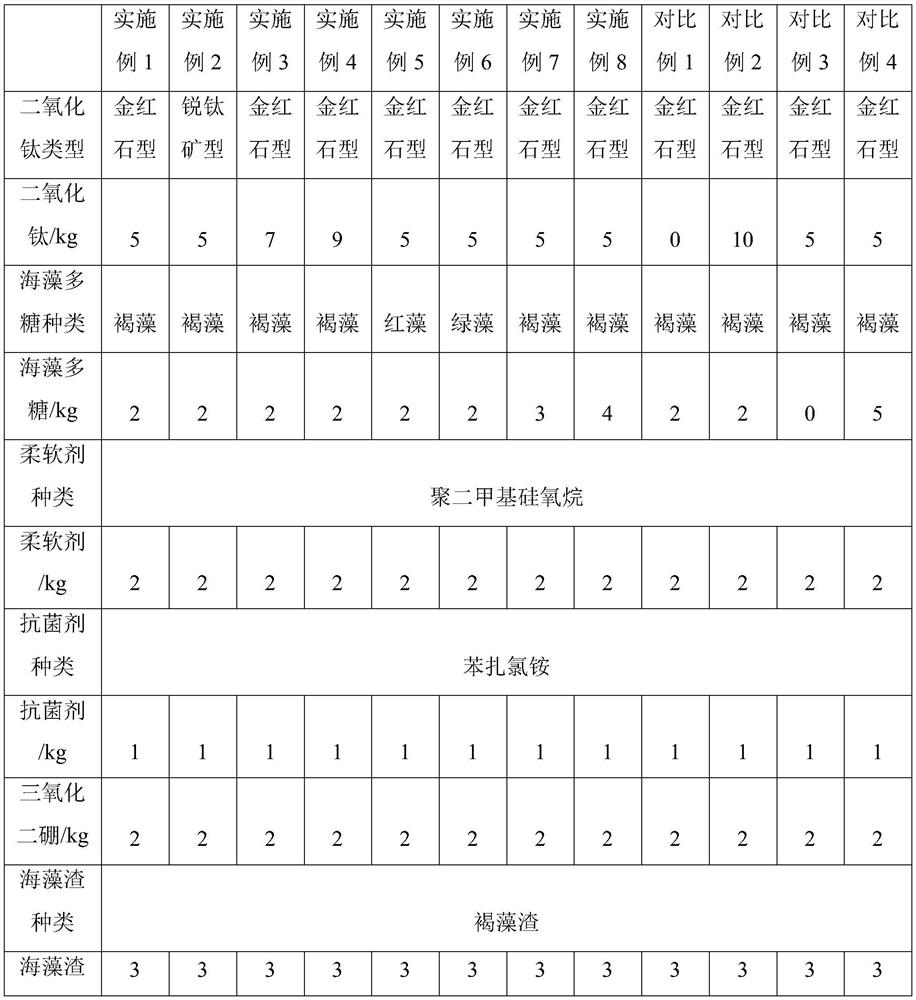

[0049] The difference between Examples 2-8 and Example 1 is that the ratio of raw materials is different, and the specific ratio of raw materials is shown in Table 1.

[0050] The raw material ratio of table 1 embodiment 2-8 and comparative example 1-4

[0051]

[0052]

[0053] performance test

[0054] Ultraviolet transmittance was measured according to GB / T18830-2009.

[0055] According to FZ / T60005-1991, the breaking strength of each group of fabrics was measured.

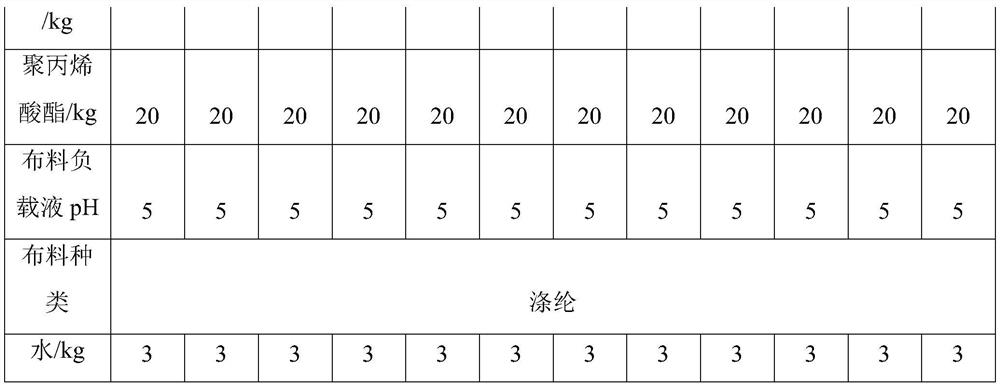

[0056] Test of chalking degree: place the prepared anti-ultraviolet light-resistant luggage fabric in the ultraviolet accelerated testing machine, and the light intensity is 0.9W / m 2 , Under the environment of ultraviolet light wavelength of 310nm, irradiate the sample for 300h, and judge the pulverization level according to the pulverization state in the table below.

[0057] Table 2 Judgment table for the degree of powdering of anti-ultraviolet light luggage fabrics

[0058]

[0059] The experime...

Embodiment 9-20

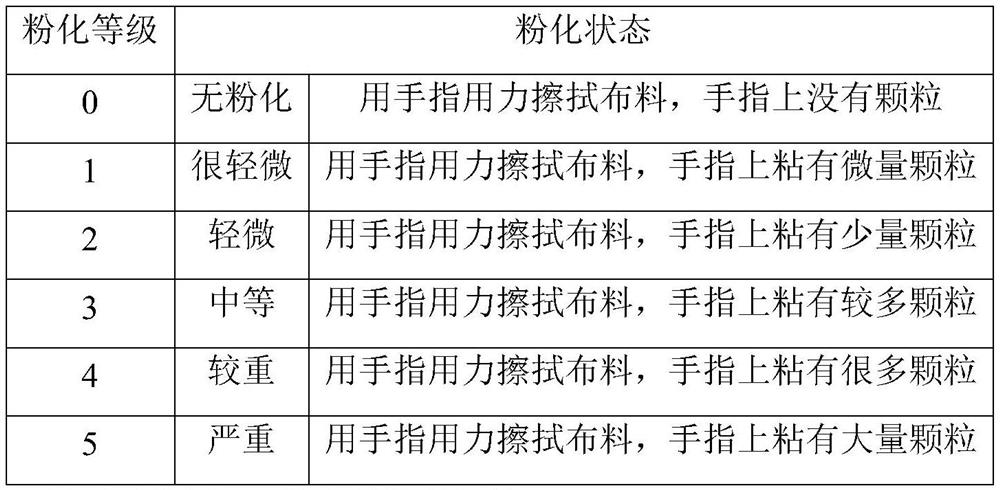

[0065] The difference between Examples 9-20 and Example 1 is that the ratio of raw materials is different, and the specific ratio of raw materials is shown in Table 4.

[0066] The raw material ratio of table 4 embodiment 9-20

[0067]

[0068]

[0069]

[0070] The ultraviolet transmittance and transverse rupture strength of the fabrics in Examples 9-20 were tested and a pulverization experiment was performed. The specific experimental data are shown in Table 5.

[0071] Table 5 Experimental data results of Examples 9-20

[0072]

[0073] According to Tables 1-5, the experimental data of Comparative Example 1 and Example 9 found that the silicone softener can increase the transverse breaking strength of the fabric. The experimental data of Comparative Example 1 and Example 10 found that within a certain range, The more silicone softeners, the more the transverse breaking strength of the fabric can be increased;

[0074] Comparing the experimental data of Example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com