A Mechanical Rope Net Compression and Release Mechanism

A release mechanism and mechanical technology, applied in space navigation equipment, transportation and packaging, tools, etc., can solve problems such as large temperature difference changes, large environmental impact, and difficulty in ensuring the reliability of electric fuses or pyrotechnics. Small compression force, easy release of bundles, reducing the effect of separate opening and release process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

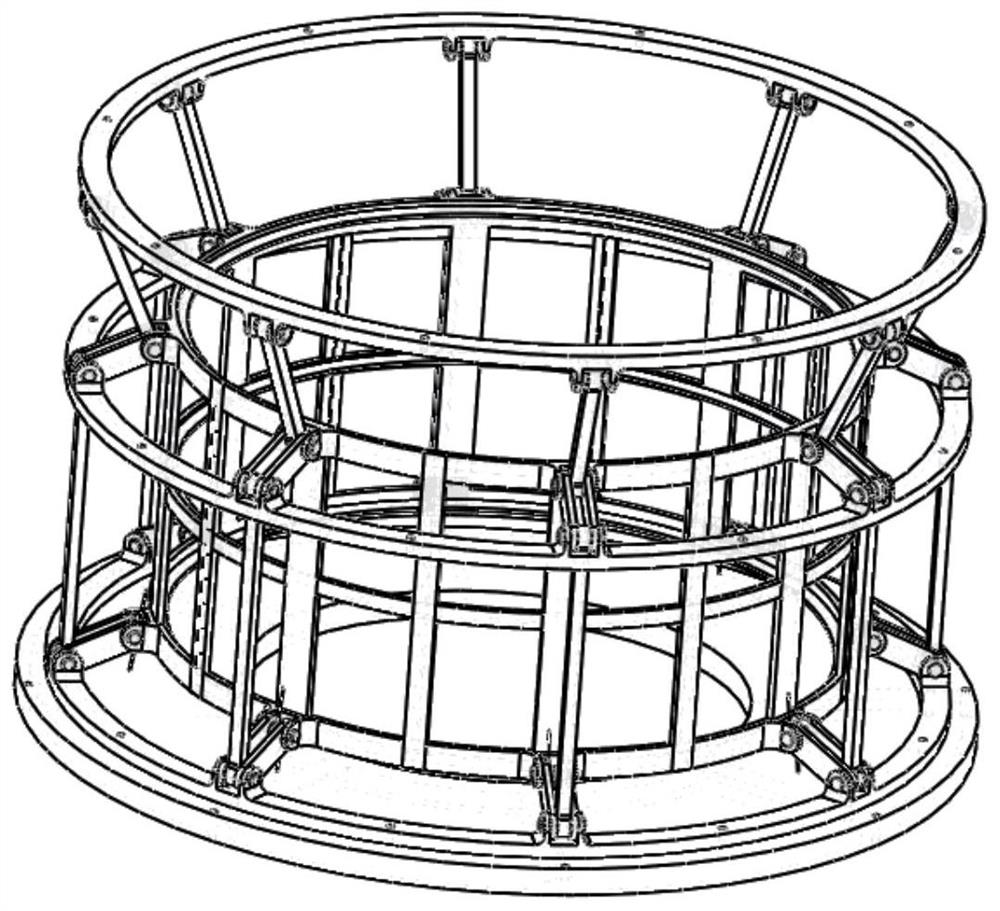

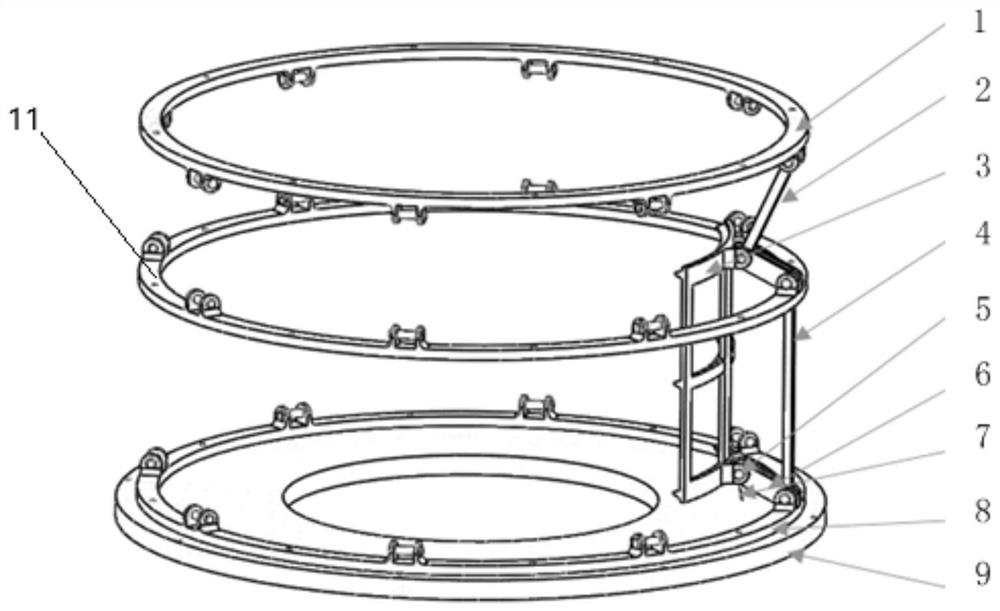

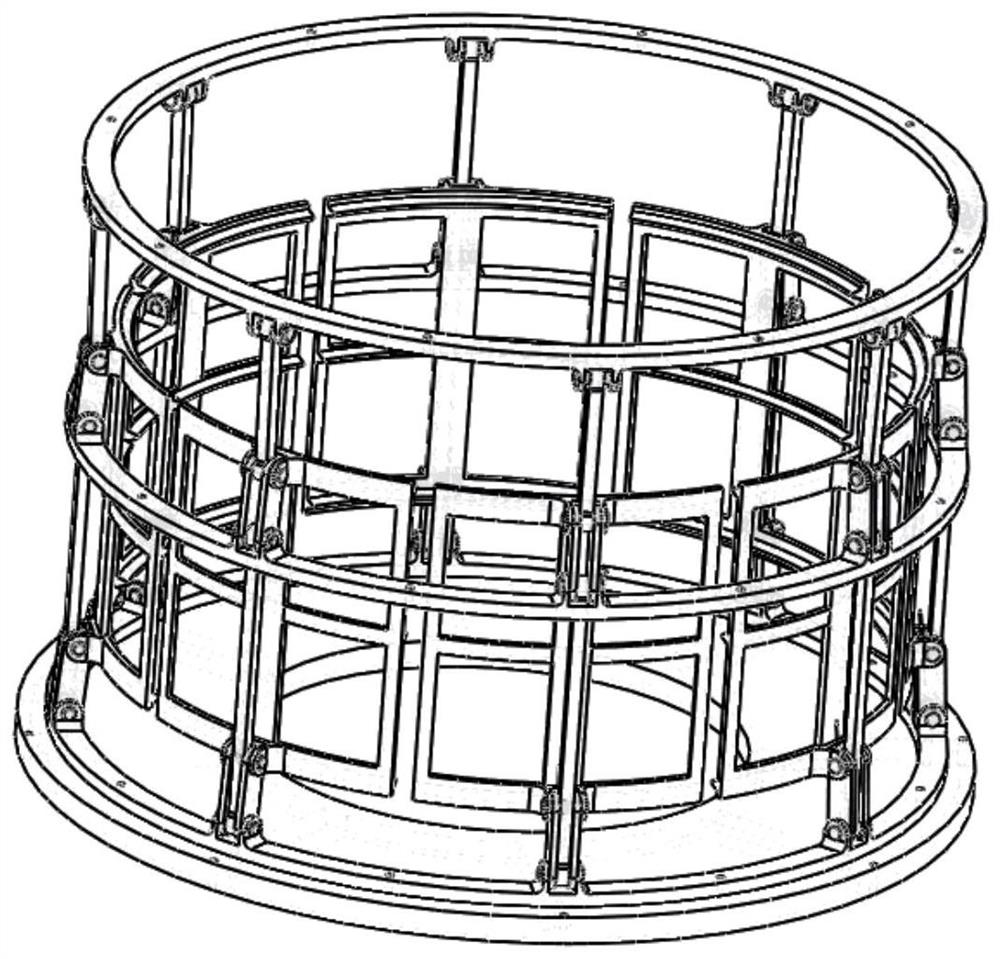

[0030] Such as Figure 1-7 As shown, a mechanical rope net compression release mechanism includes an upper fixing ring 1, an upper connecting rod 2, a pressing plate 3, a long connecting rod 4, a pin shaft 5, a short connecting rod 6, a torsion spring 7, a lower fixing Circle 8, chassis 9.

[0031] The short connecting rod 6 and the long connecting rod 4 are installed in the position corresponding to the lower fixed ring 7 with the pin shaft, and the stop piece is loaded into the groove corresponding to the pin shaft; the other end of the short connecting rod 6 is connected with the corresponding position of the pressing plate 3, and is Insert the pin shaft and install the blocking piece; install the short connecting rod 6 and the upper connecting rod 2 at the corresponding position on the other end of the pressing plate 3, insert the pin shaft and install t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com