Carton packaging sealing and laminating machine

A laminating machine and sealing technology, applied in packaging sealing/fastening, packaging, transportation packaging, etc., can solve problems such as arm soreness, low error rate, easy damage to boxes, etc., and achieve the effect of increasing moving speed and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

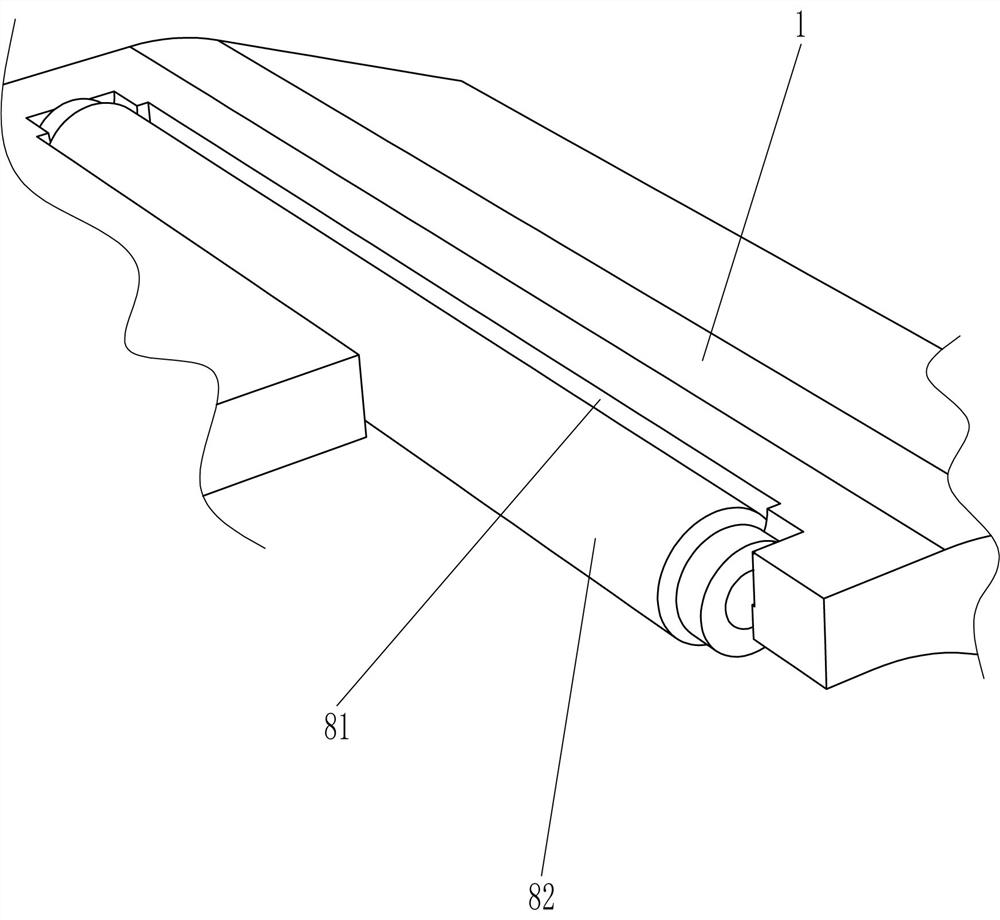

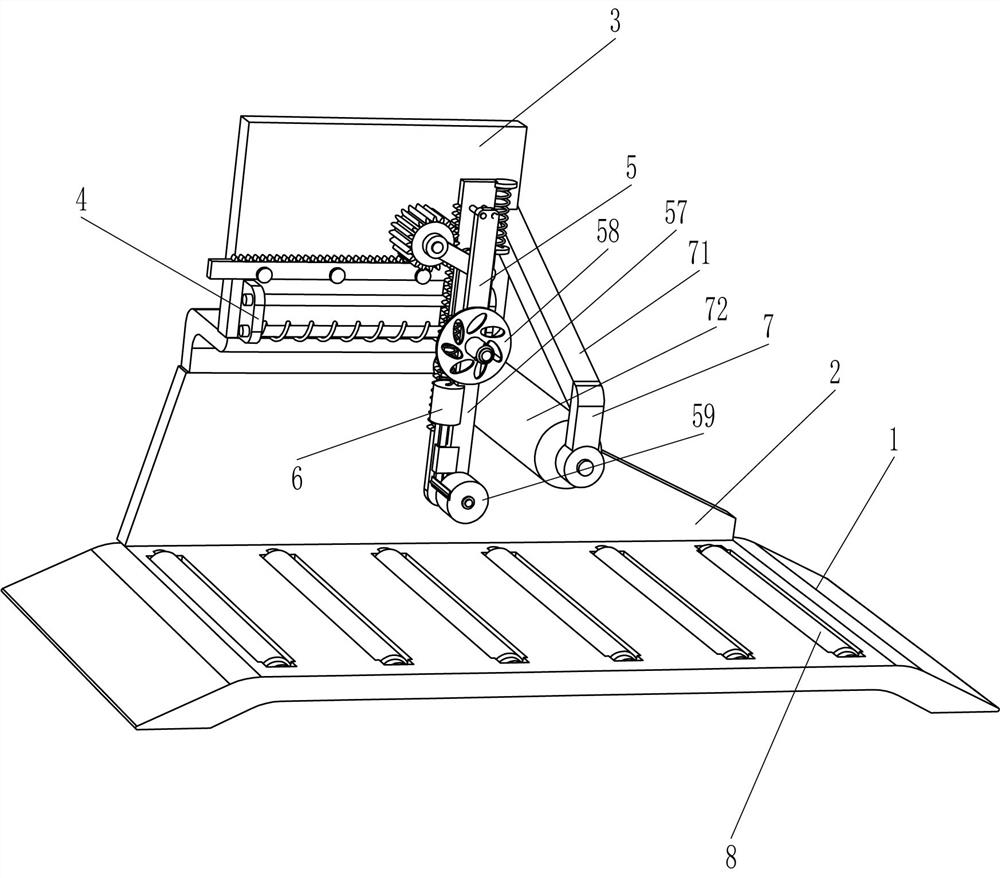

[0047] A carton packaging and sealing laminating machine, such as figure 1 As shown, it includes a placement board 1, a vertical board 2, a mounting board 3, a fitting mechanism 4 and a lifting mechanism 5, the rear side of the top of the placement board 1 is connected with a vertical board 2, and the top of the vertical board 2 is provided with a mounting board 3, and the mounting board The lower part of the front side of 3 is provided with a bonding mechanism 4, and the upper part of the front side of the mounting plate 3 is provided with a lifting mechanism 5, and the lifting mechanism 5 is connected with the bonding mechanism 4.

[0048] When people need to seal the case, the case is first placed on the right side of the placement plate 1, then the adhesive tape is placed on the lifting mechanism 5, and one end of the adhesive tape is pasted on the case seal, and then the case is promoted to move to the left. When fitting with the lifting mechanism 5, the adhesive tape is ...

Embodiment 2

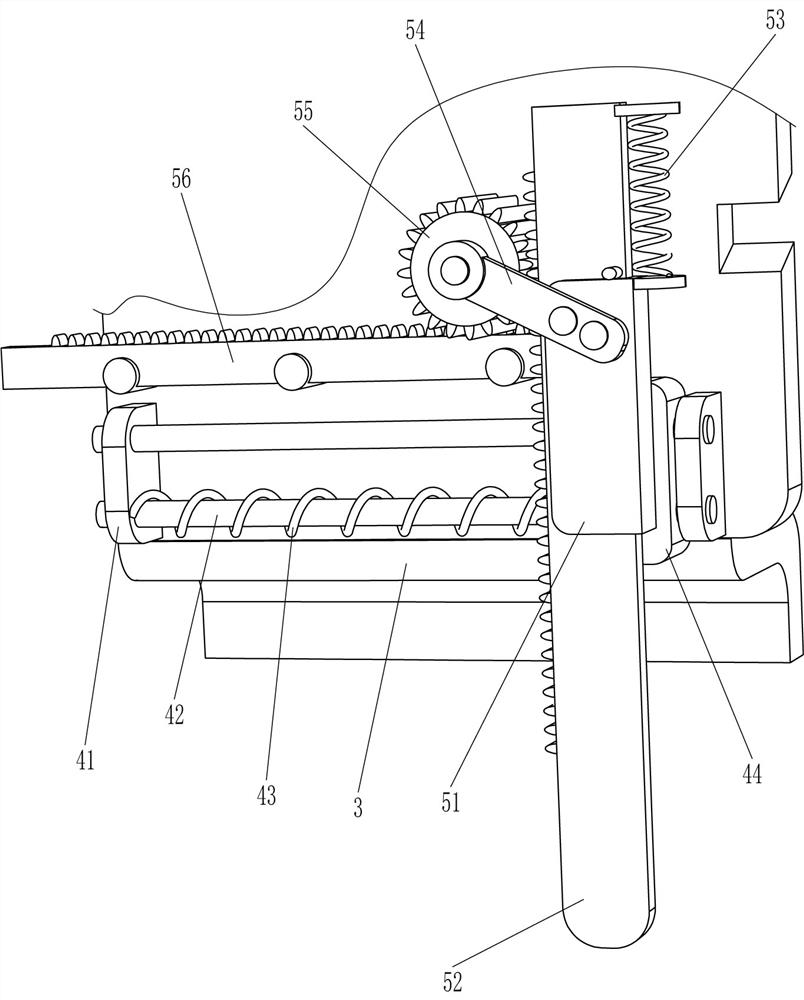

[0050] On the basis of Example 1, such as Figure 1-2 As shown, the bonding mechanism 4 includes a mounting seat 41, a guide rod 42, a first spring 43 and a guide sleeve 44, and the mounting plate 3 is connected to the mounting seat 41 on both sides of the lower part of the front side, the upper and lower sides of the mounting plate 41. Both guide rods 42 are connected, guide sleeves 44 are slidingly connected between the guide rods 42, the front side of the guide sleeves 44 is connected with the lifting mechanism 5, and a first The spring 43, the first spring 43 is sleeved on the outer side of the guide rod 42 on the lower side.

[0051] When the box moves to fit the lifting mechanism 5, it drives the lifting mechanism 5 to move to the left, drives the guide sleeve 44 to move to the left, the first spring 43 is compressed, and then, under the action of the first spring 43, the lifting mechanism 5. The guide sleeve 44 moves to the right and resets.

[0052] Lifting mechanism...

Embodiment 3

[0055] On the basis of Example 2, such as Figure 3-4 As shown, a cutting mechanism 6 is also included, and the cutting mechanism 6 includes a slider 61, a slide rail 62, a cutter 63, a fitting rod 64, a weight 65 and a third spring 66, and the lower left side of the fixed plate 57 is slidingly connected There is a weight 65, the lower part of the left side of the fixed plate 57 is connected with a slide block 61, the slide block 61 is positioned at the underside of the weight 65, the slide rail 62 is slidably connected in the slide block 61, and the bottom of the slide rail 62 is connected with a cutter 63 for cutting. The left side of the knife 63 is connected with a fitting rod 64 , the top of the slide rail 62 is connected with the weight 65 , and the third spring 66 is connected between the top of the weight 65 and the upper left side of the fixed plate 57 .

[0056] When the box and the pressure roller 59 are separated, the fixed plate 57 moves downward, and the downward...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap