Shear-fork type distance adjusting device

A technology of adjusting devices and scissors, which is applied in the direction of internal accessories, etc., can solve the problems of lower production efficiency, long time consumption, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

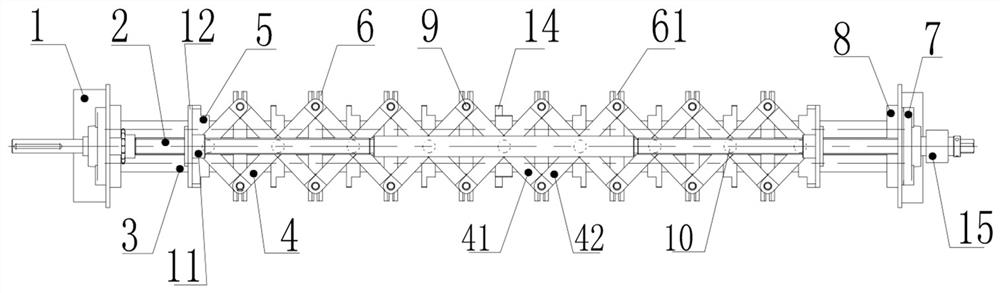

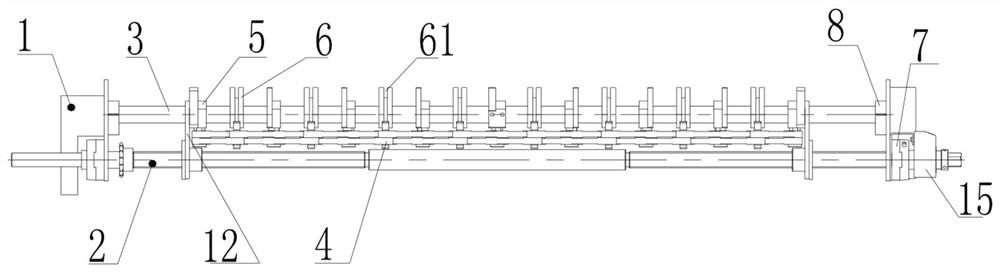

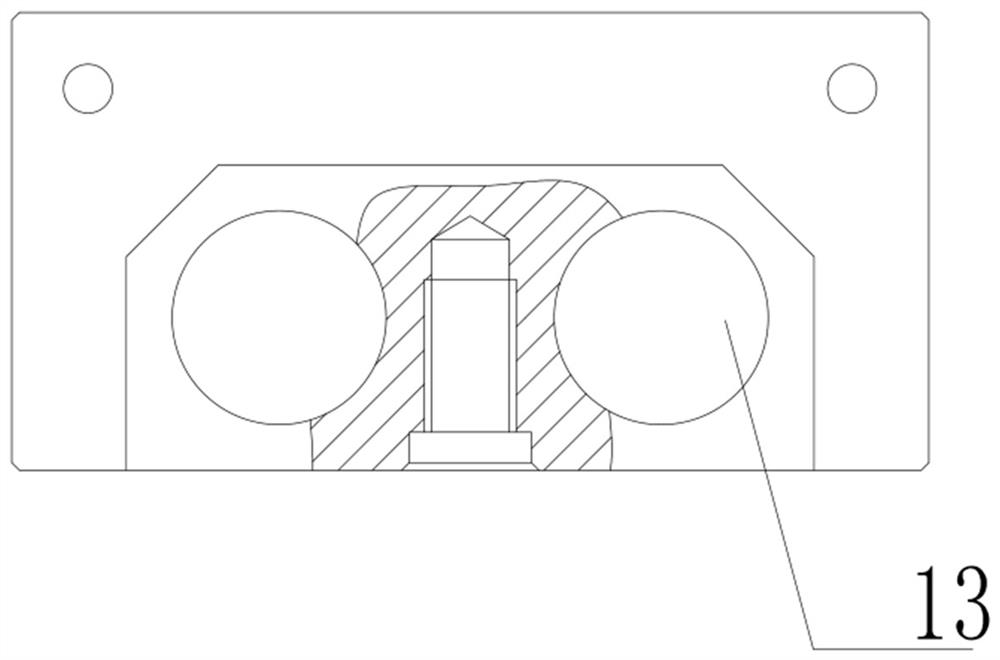

[0011] like Figure 1-2 As shown, a scissors-type spacing adjustment device includes a frame 1, a screw rod 2 with threads at both ends and opposite rotation directions, a guide rail 3, a scissor mechanism 4, a first slider 5 and a second slider 6, The screw mandrel 2 is fixed on the frame 1 through a bearing with a seat 7, the guide rail 3 is fixed on the frame 1 through a fixed block 8, and the scissors mechanism 4 includes a first connecting rod 41 and a second connecting rod with the same length. Connecting rod 42, the end of the first connecting rod 41 and the second connecting rod 42 are hinged by the first latch 9, and the middle part of the first connecting rod 41 and the second connecting rod 42 is hinged by the second latch 10; The block 5 and the second slide block 6 are set on the guide rail 3 at intervals, and the two ends of the screw rod 2 are covered with nuts 11 that match the threads of the screw rod 2, and the nuts 11 at the two ends of the screw rod 2 pass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com