Shore power cable conveying device

A cable transmission and cable technology, which is applied in the field of shore power cable transmission devices, can solve problems such as frictional damage, short service life of cables, easy strain of the first main cable, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

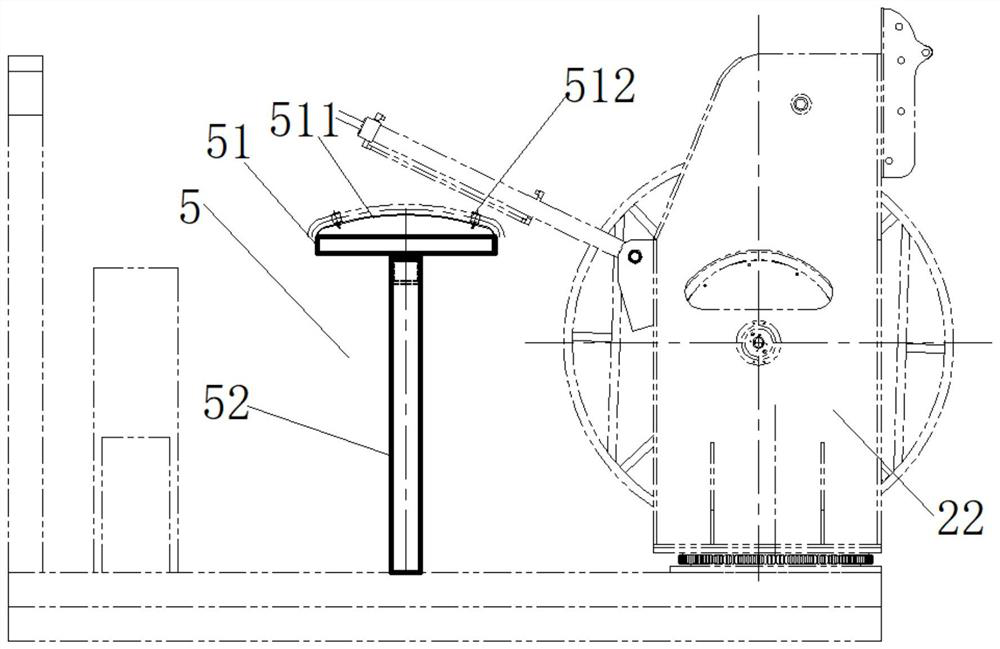

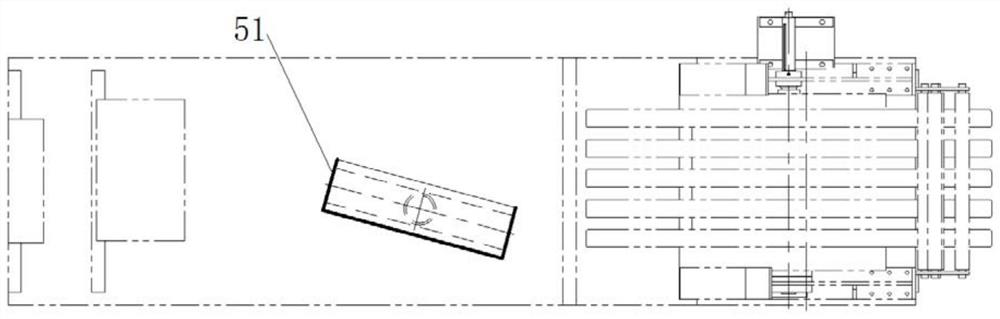

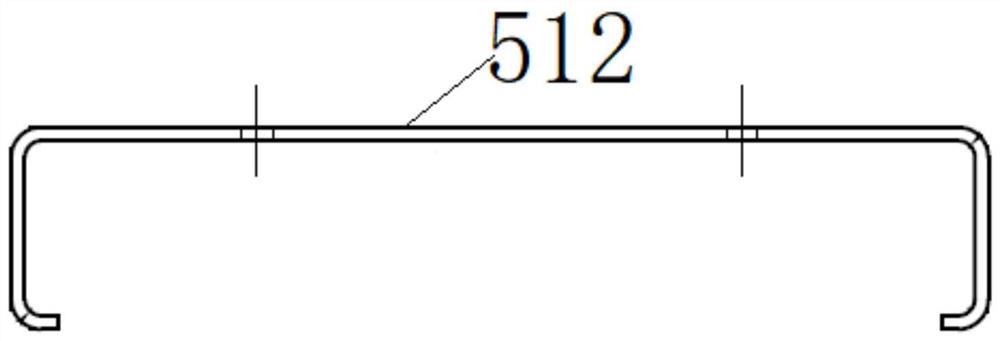

[0051] This embodiment provides a shore power cable transmission device, such as Figure 4 and Figure 5 As shown, it includes a base 1 , a frame, a reel, a cable transfer box 4 and a first cable guiding mechanism 5 .

[0052] Wherein, the frame is rotatably arranged on the base 1 . The frame includes a bottom plate 21 and two lateral support plates 22 vertically arranged on the bottom plate 21. The top of the base 1 is rotatably provided with a circular rotary support plate, and the bottom plate 21 is arranged on the circular rotary support plate. The base 1 is provided with a hydraulic motor, and the driving end of the hydraulic motor is connected to a circular rotary support plate through a gear to drive the frame to rotate.

[0053] The reel is rotatably arranged between the two lateral support plates 22 of the frame; the reel includes a cylinder body 31 and a plurality of cable retaining rings 32, and the plurality of cable retaining rings 32 are parallel to the axis of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com