A compacting device for road construction

A tamping device and road construction technology, which is applied in the direction of roads, roads, road repairs, etc., can solve problems such as weak adaptability, inability to adjust the tamping strength, and inability to meet the needs of road construction, so as to achieve the effect of improving adaptability and improving tamping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

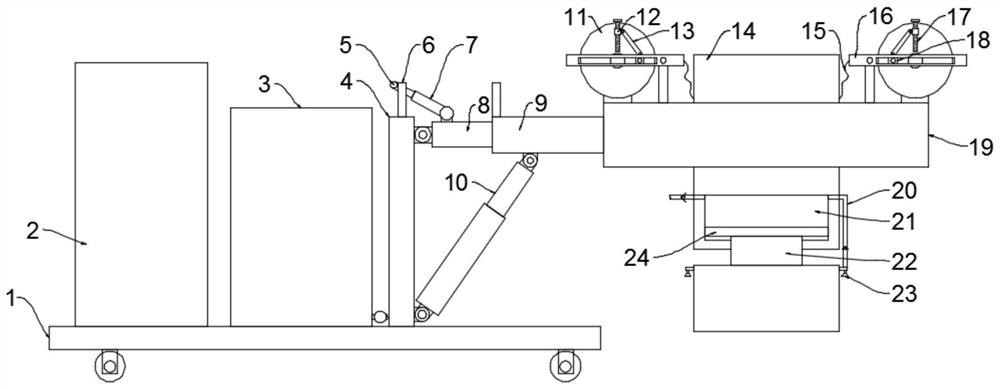

[0025] see figure 1 , in an embodiment of the present invention, a tamping device for road construction, including a tamping unit and a driving car 1 for driving the tamping unit, a counterweight 2 is installed on the end of the driving car 1 away from the tamping unit, and the tamping unit includes a tamping unit Block 14, a mounting frame 19 for installing the tamping block 14, a driving assembly for driving the tamping block 14 to move, and a mounting frame assembly for connecting the mounting frame 19 and the driving vehicle 1, and the tamping block 14 is slidably installed on the mounting frame 19 inside, on the installation frame 19, there are drive components symmetrically installed on both sides of the tamping block 14, the drive components include a first motor, a turntable 11, a drive rod 16 and an adjustment mechanism for the range of motion of the drive rod 16, and the first motor is fixed Installed on the installation frame 19, the output shaft of the first motor ...

Embodiment 2

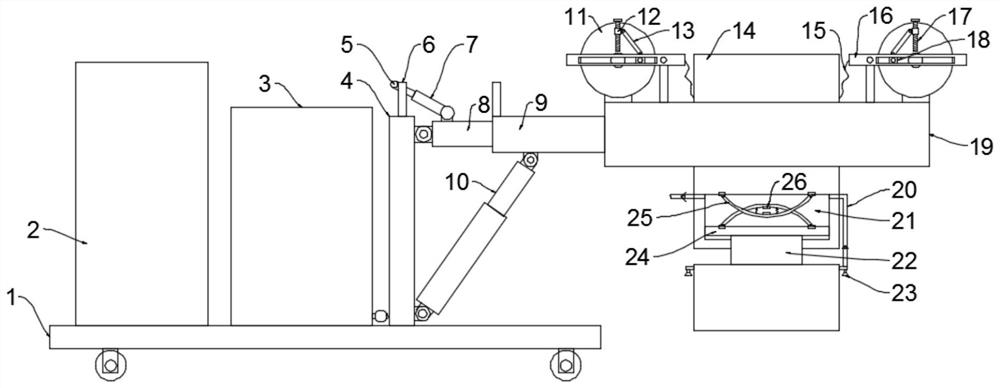

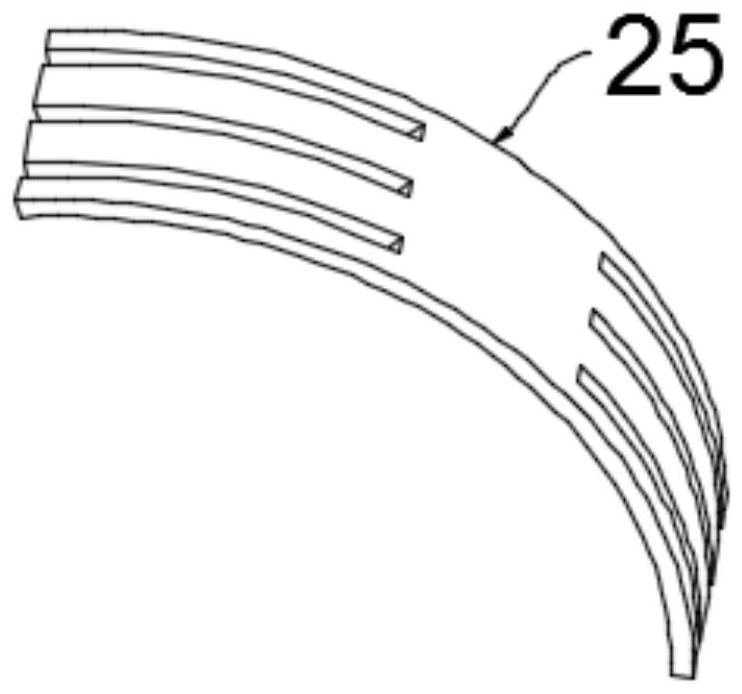

[0029] see Figure 2-3 The difference between this embodiment of the present invention and Embodiment 1 is that a buffer assembly is also provided in the chamber 21, and the buffer assembly includes an elastic member 25 and a magnet 26, and the two elastic members 25 are arc-shaped and symmetrical Setting, two elastic parts 25 are slidably installed on the piston plate 24 and the top wall of the chamber 21 respectively, the two ends of the two elastic parts 25 are rake-shaped and intersected and misplaced, and the middle parts of the two elastic parts 25 are respectively fixed with magnets 26 , the opposite faces of the two magnets 26 are the same magnetic pole, and the two elastic members 25 are also fixedly connected with springs on both sides of the two magnets 26, which can perform good buffering and shock absorption, and prolong the service life of the tamping block 14.

[0030] The working principle of the present invention is: when working, the first motor drives the tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com