Door type emergency leakage stopping device and method for underground diaphragm wall

An underground diaphragm wall and door-type technology, which is applied in excavation, underwater structures, water conservancy projects, etc., can solve problems such as threats to the safety of foundation pits and surrounding buildings, long time-consuming plugging, and loose joints in groove sections, etc., to achieve economical The benefits and social benefits are good, the plugging effect is quick, and the effect of not polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

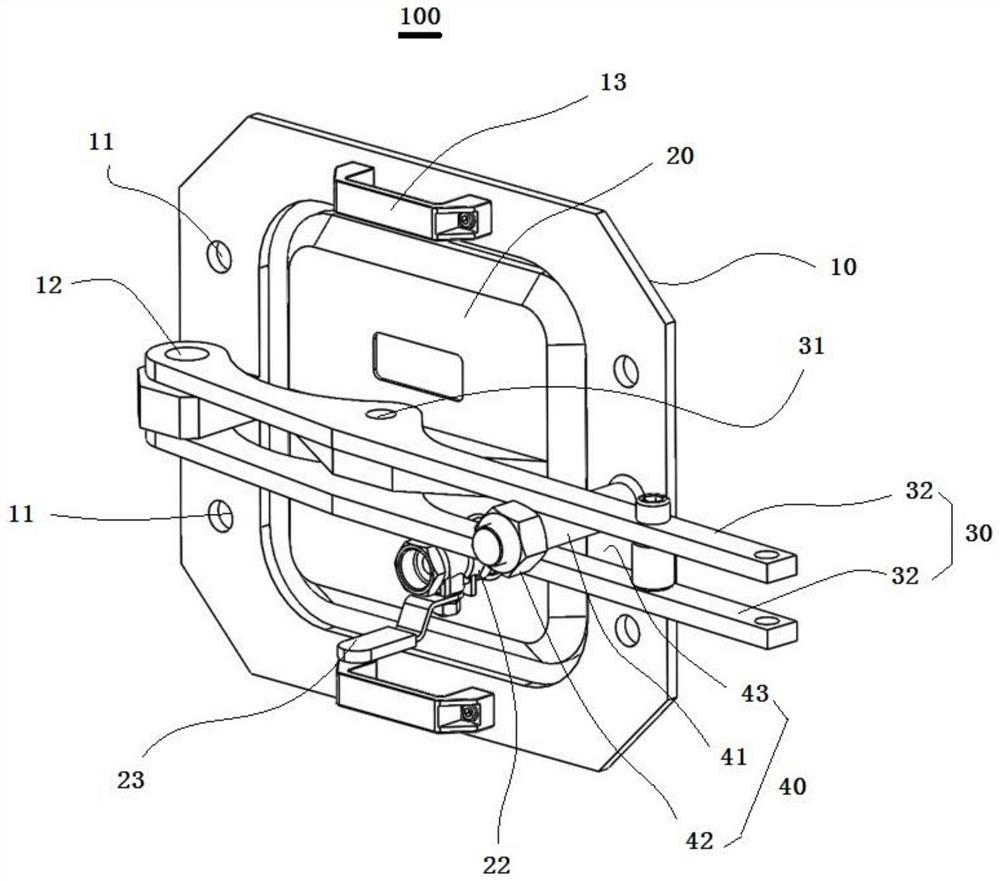

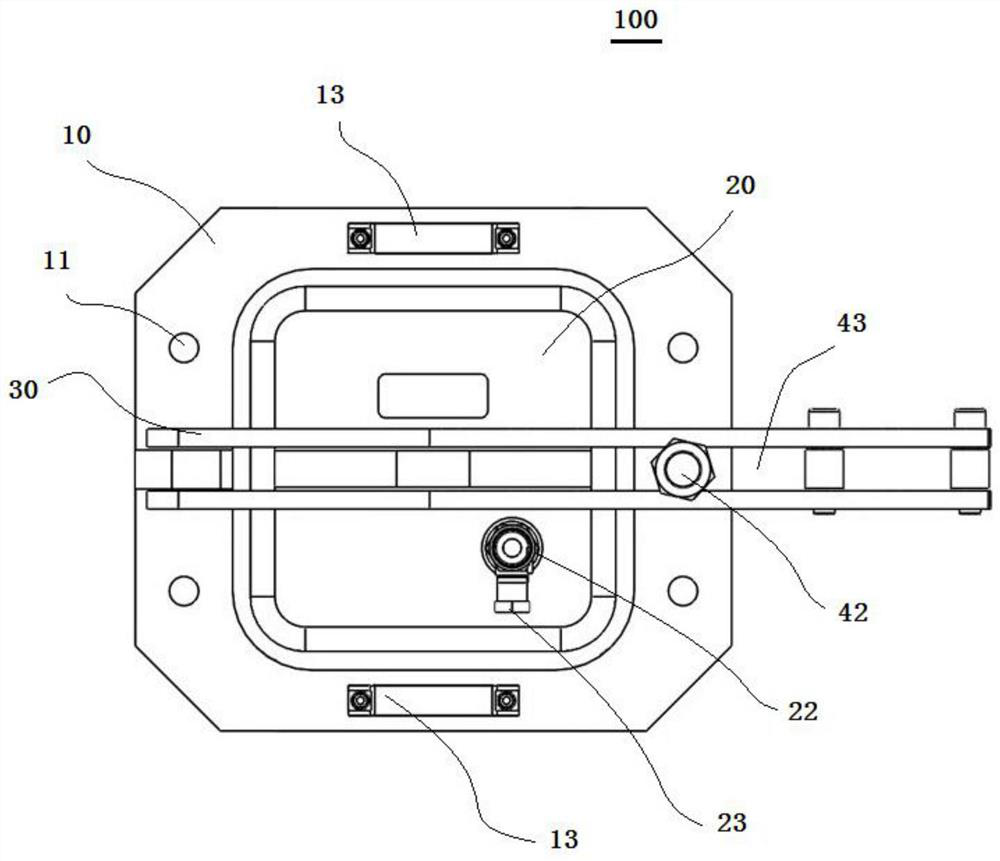

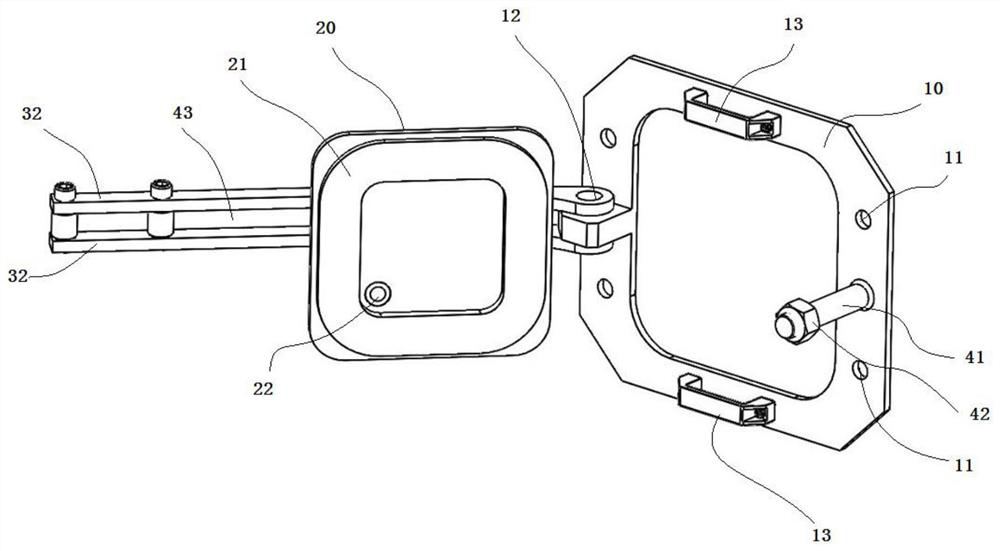

[0044] Such as Figure 1 to Figure 4 As shown, the present embodiment provides a door-type emergency leak plugging device 100 for an underground diaphragm wall, which is used for installation at the seepage of the underground diaphragm wall. The door-type emergency plugging device 100 includes: a frame 10 , a plugging door 20 , a pressing handle 30 and a safety structure 40 . The frame 10 is used to be installed at the leakage location of the underground continuous wall. The frame 10 has an anchor bolt hole 11 passing through the upper surface and the lower surface thereof, and is used to pass an expansion anchor bolt to install the door-type emergency leakage plugging device 100 at the leakage place of the underground continuous wall. The pressing handle 30 protrudes from one end of the frame 10 to the opposite end of the frame 10 . One end of the pressing handle 30 is movably connected to one end of the frame 10 through the first connecting member 12 , so that the other en...

Embodiment 2

[0058] see Figure 1-Figure 4 , the present invention also provides an emergency plugging method for an underground diaphragm wall, which uses the above-mentioned door-type emergency plugging device for plugging, and the method includes the following steps:

[0059] Step 100, find the leakage location of the underground diaphragm wall, clean and polish the surface of the underground diaphragm wall around the leakage location, and remove the floating mud and easily falling cement soil on the surface of the underground diaphragm wall;

[0060] Step 200, according to the size of the hole at the seepage of the underground diaphragm wall, select a suitable size of the door-type emergency plugging device, and drive expansion anchor bolts into the underground diaphragm wall according to the position of the anchor bolt hole 11;

[0061] Step 300, install the door-type emergency plugging device and tighten the bolts, so that the rubber ring 21 is close to the surface of the underground...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com