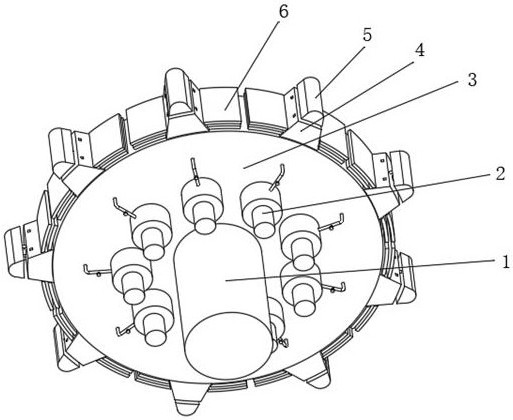

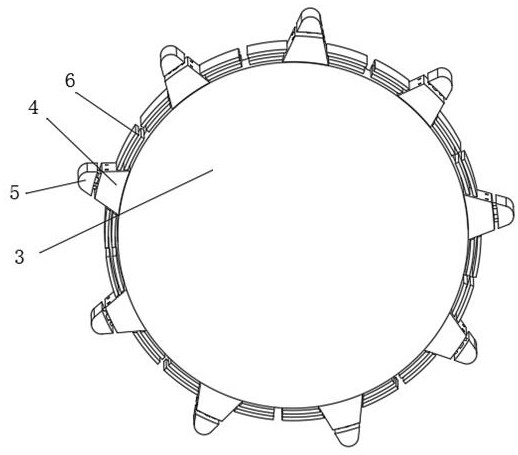

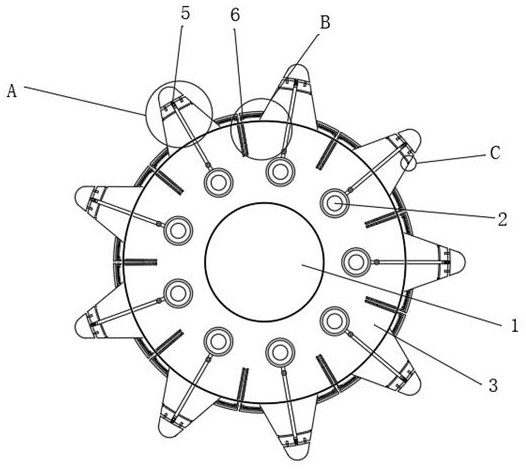

Self-cleaning cylindrical gear for new energy electric logistics vehicle and manufacturing process of self-cleaning cylindrical gear

An energy electric animal, cylindrical gear technology, applied in the direction of gear lubrication/cooling, belt/chain/gear, cleaning method using tools, etc. meshing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0032] As an embodiment of the present invention, the cleaning assembly 6 includes a scraper 61, a sliding block 62, a guide rod 63, a contraction spring 64, a supporting plate 65, a limit plate 66, an insertion rod 67, a return spring 68 and a rod hole 69, The inside of the chainring 3 is provided with a rod hole 69, and one end of the insertion rod 67 is mated and inserted in the rod hole 69, and a return spring 68 is fixedly connected between the bottom end surface of the insertion rod 67 and the bottom side wall of the rod hole 69, and the insertion rod 67 A supporting plate 65 is welded on the top of the supporting plate, and a sliding hole is provided inside the supporting plate 65. A guide bar 63 is installed between the two ends of the sliding hole, and a sliding block 62 is arranged in the sliding hole. hole, the guide rod 63 is set through the through hole, and one end of the guide rod 63 is sleeved with a contraction spring 64, and the two ends of the contraction spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com