Natural gas liquefaction device and method capable of hydrocarbon removal and nitrogen removal synchronously

A liquefaction device, natural gas technology, applied in liquefaction, refrigeration and liquefaction, gas fuel, etc., can solve the problems of increasing LNG product volume, reducing denitrification operation energy consumption, etc., to reduce methane content, reduce device operation energy consumption, Effect of improving methane recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

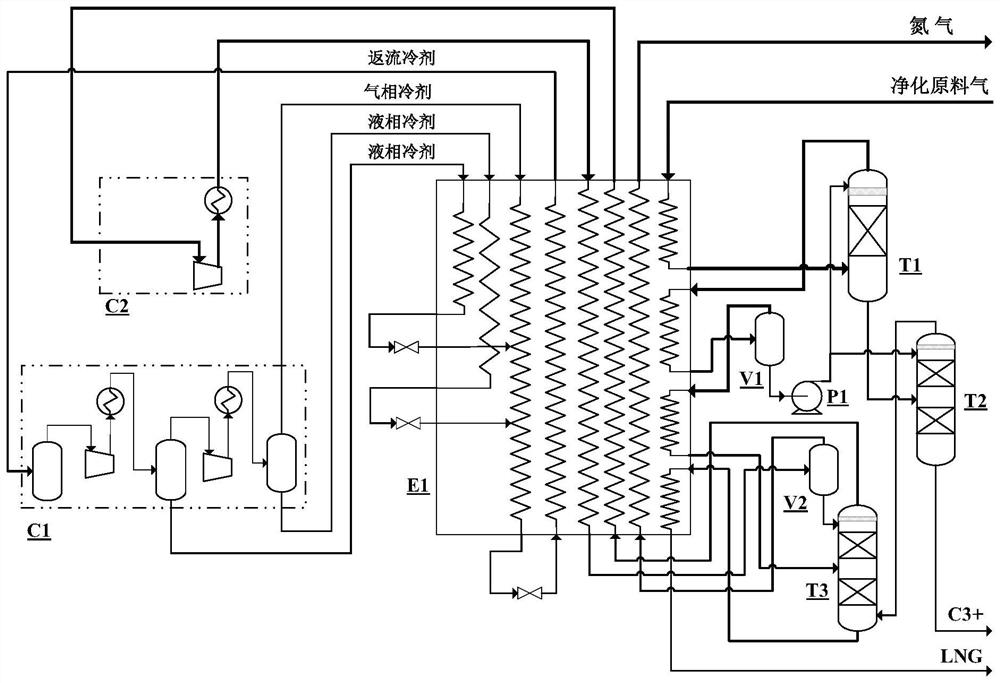

[0032] Such as figure 1 As shown, a natural gas liquefaction device for simultaneous dehydrocarbon and denitrogenation includes cold box E1, heavy hydrocarbon removal tower T1, low temperature separator V1, denitrogenation gas-liquid separator V2, deethanizer T2, denitrogenation tower T3, Denitrogenation gas cycle compressor C2 and cryogenic condensate pump P1; cold box E1 is connected with heavy hydrocarbon removal tower T1 and low temperature separator V1 respectively; the gas phase outlet of low temperature separator V1 is connected with cold box E1, and cold box E1 is connected with denitrification The tower T3 is connected; the heavy hydrocarbon removal tower T1 is connected with the deethanizer T2, and the liquid phase of the low-temperature separator V1 is pressurized by the low-temperature condensate pump P1, and then respectively connected with the heavy hydrocarbon removal tower T1 and the deethanizer T2; The gas phase outlet of the alkane tower T2 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com