Plasma liquid phase treatment device and method for fly ash

A processing device and processing method technology, applied in chemical instruments and methods, chemical/physical/physical chemical processes, chemical/physical processes and other directions of energy application, can solve the problems of complex devices and high operating energy consumption, and reduce device operation. Low energy consumption, low operating energy consumption, high efficiency and non-toxic treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

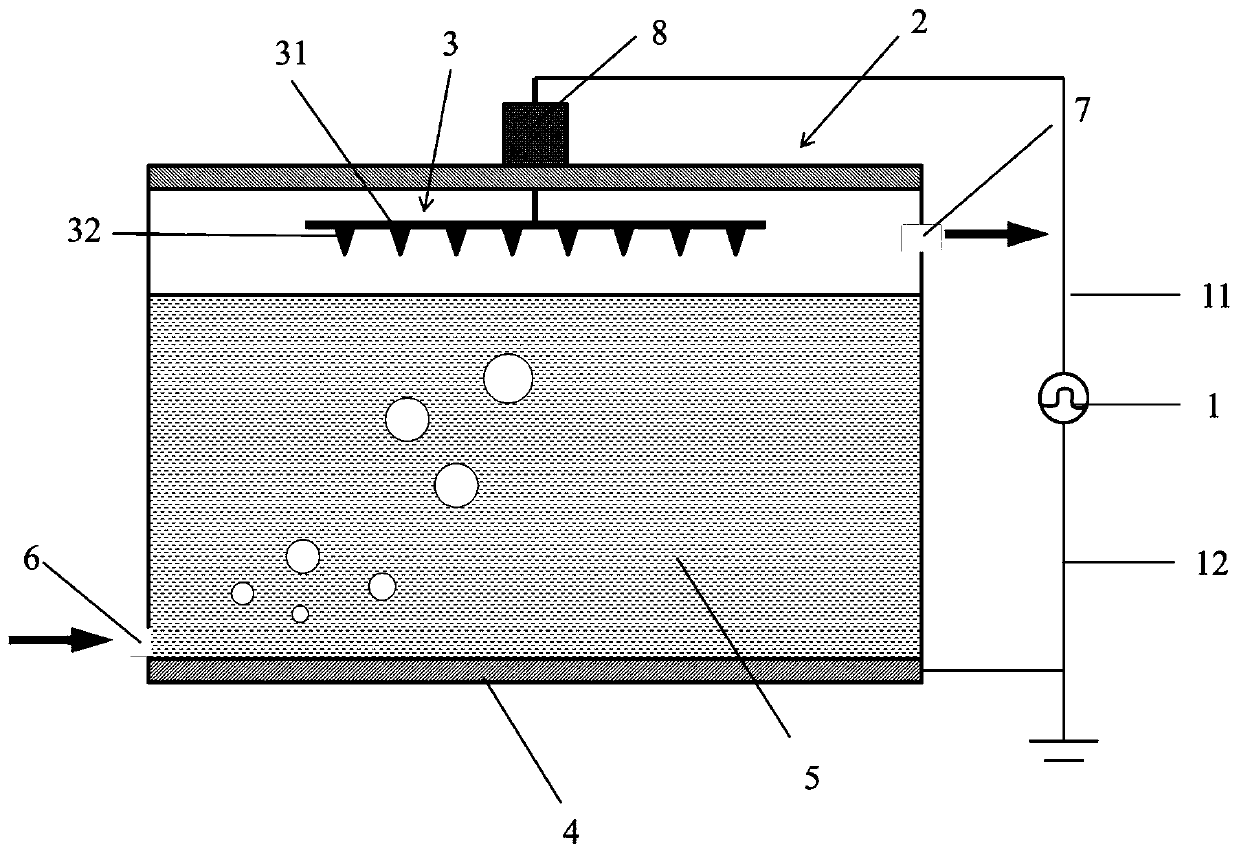

[0040] A plasma liquid phase processing device for fly ash according to the present invention is as figure 1 As shown, the device includes a high-voltage power supply 1 and a reactor; the reactor is cylindrical and includes a housing 2, a needle electrode 3 and a plate electrode 4 disposed in the housing 2, and the lower part of the housing 2 is provided with an air inlet 6 , the upper part is provided with an exhaust hole 7, and the needle electrode 3 includes a circular electrode plate 31, and conical electrodes 32 of equal size are evenly distributed on the electrode plate 31;

[0041] The needle electrode 3 is connected to the top of the housing 2 through an insulator 8, and the plate electrode 4 has the same area as the bottom of the housing 2 and is attached and fixed. The center lines coincide, and a fly ash processing chamber 5 is formed between the needle electrode 3 and the plate electrode 4 .

[0042] The shell 2 is made of polytetrafluoroethylene; the needle elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com