Method for liquefying and rectifying coalbed methane containing oxygen

A coalbed methane and rectification technology, which is applied in the field of liquefaction and rectification of oxygen-containing coalbed methane, can solve the problems of low methane recovery rate, low product recovery rate, difficult operation, etc., and achieve safe and reliable operation process and low power consumption of process flow , easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

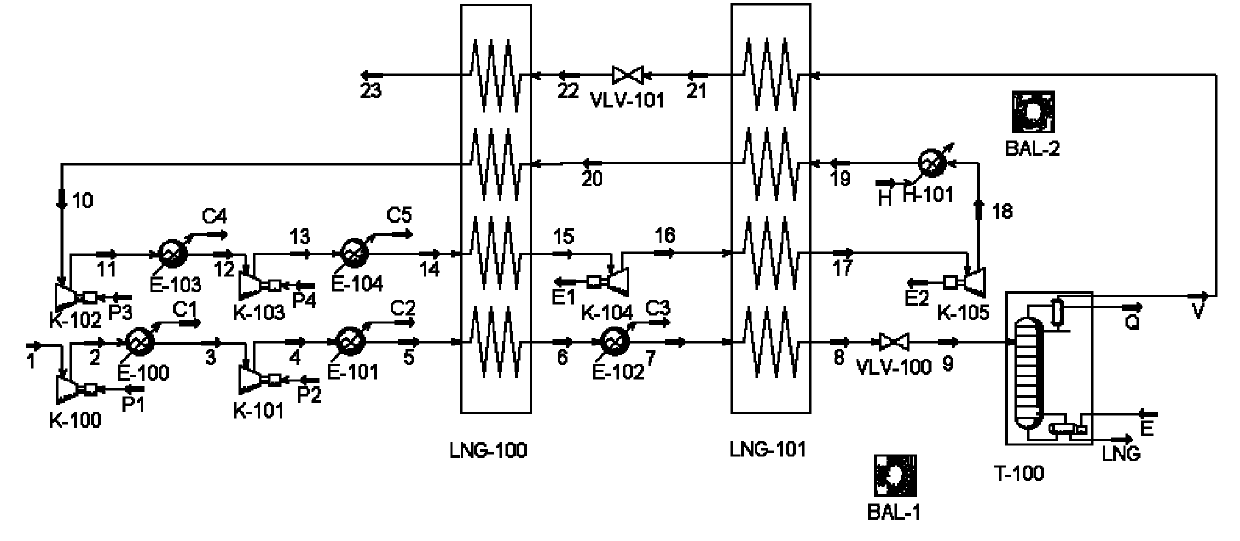

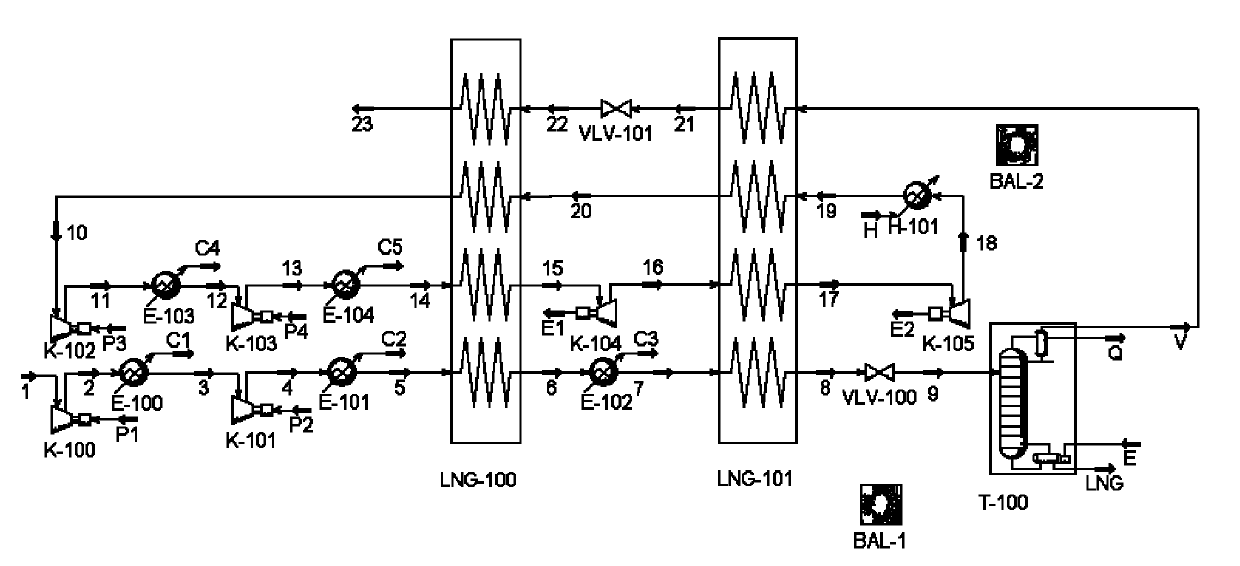

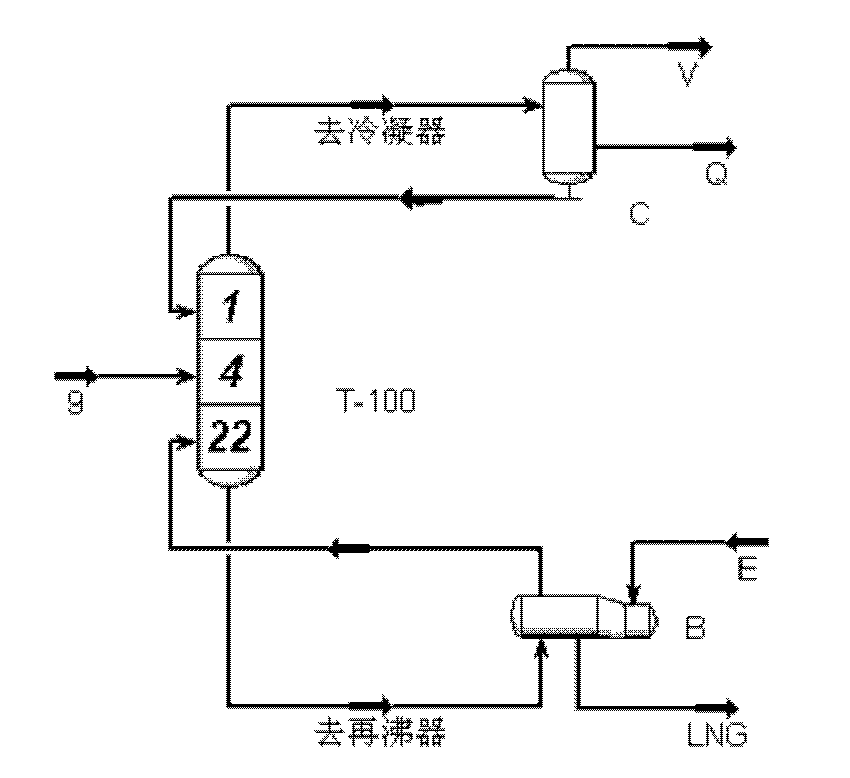

[0020] For oxygen-containing coalbed methane with methane, nitrogen and oxygen components of 68.89%, 24.57% and 6.54% respectively, the liquefaction and rectification process includes the following steps:

[0021] Step 1. CBM is firstly compressed to 1.8MPa by compressors K-100 and K-101, and then enters heat exchanger LNG-100 for pre-cooling to -90°C. The pre-cooled CBM is cooled in cooler E-102 , and then enter the heat exchanger LNG-101 for further cooling and liquefaction. The liquefied coal bed gas is decompressed to 0.2MPa through the throttle valve VLV-100 and then enters the rectification tower T-100. The pressure separated from the top of the rectification tower is 0.19 The impurity gas of MPa, the liquid product LNG of 0.195MPa is obtained at the bottom. In order to reduce the energy consumption of the entire liquefaction and rectification process, the low-temperature impurity gas flowing out from the top of the tower first returns to the secondary heat exchanger for...

Embodiment 2

[0025] For low-concentration oxygen-containing coalbed methane with methane content of 42% and air content of 58%.

[0026] Step 1. CBM is compressed to 1.1MPa by compressors K-100 and K-101, and then enters heat exchanger LNG-100 for pre-cooling to -90°C. The pre-cooled CBM is cooled in cooler E-102. Then enter the secondary heat exchanger LNG-101 for further cooling and liquefaction. The liquefied coal bed gas is decompressed to 0.2MPa through the throttle valve VLV-100 and then enters the rectification tower. Impurity gas, the liquid product LNG of 0.195MPa is obtained at the bottom. In order to reduce the energy consumption of the entire liquefaction and rectification process, the low-temperature impurity gas flowing out from the top of the tower first returns to the secondary heat exchanger for cooling recovery, and the impurity gas coming out of the secondary heat exchanger passes through the throttle valve VLV- 101 The pressure drop is 0.11MPa, and the gas from the thr...

Embodiment 3

[0030] For low-concentration oxygen-containing coalbed methane containing 80.7%, 16.77% and 2.53% of methane, nitrogen and oxygen respectively.

[0031] Steps 1 and 2 are the same as steps 1 and 2 in Example 1

[0032] Step 3. The analysis results of the explosion limit theory and the HYSYS simulation results confirm that there is no need for preliminary deoxygenation of the feed gas, and the entire liquefaction and rectification process can be guaranteed by controlling the output of the bottom product of the rectification tower at 0.7882 kmol / h The operation safety of the process, while the methane recovery rate is as high as 97.66%, and the product purity is as high as 99.99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com